Aug

26

A New 5 Stroke Internal Combustion Engine

August 26, 2009 | 54 Comments

Never count out the leaders in real world technology. For readers familiar with auto racing the name Ilmor Engineering will sound a claxon. Ilmor is a creature of some sort of partnership with legend Roger Penske as a co-owner and surely a managing role of some kind. Honda, of motorcycle and auto fame is the major racing engine customer for the whole of the U.S. Indy car program running on ethanol and some of the worldwide Formula One teams. It comes as no surprise this company is on the bloodiest edge of technological development in internal combustion engine design.

Ilmor is going to develop a “5-stroke”, yes – that’s 5-stroke, engine up to auto scale. Ilmor has already shown Europe the lab model at the Stuttgart Engine Expo. The next engine, more of a test engine will be installed in an automobile. Now, its not said if the test auto will be road type or racing type, but real world testing will build out some more foundation under the lab model’s results.

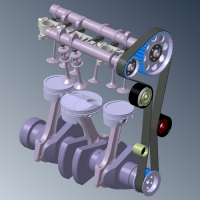

The patented 5-stroke concept, which was invented by Gerhard Schmitz, utilizes two fired cylinders operating on a conventional 4-stroke cycle, which alternately exhaust into a central expansion cylinder, where the hot exhaust gases act on a third cylinder. The third cylinder is an additional low-pressure expansion cylinder decoupled from the expansion and compression processes of the 4-stoke pair, and enables the optimum expansion ratio to be selected independently of the compression ratio.

From that one has learned the expansion ratio, the value between the intake air into the 4-stoke cylinder and its exhaust gases are of considerable interest. The engine runs an overall expansion ratio in the region of 14.5:1, which approaches the ratio of a diesel engine. The advantage to following the expansion ratio in the design is the compression ratio can be reduced to delay knock (pre ignition, where the conditions inside the combustion chamber ignite the air fuel mixture) onset without a reduction in performance. These insights in the use of the thermodynamics has the running of the lab engine producing impressive fuel consumption readings over a very wide operating range.

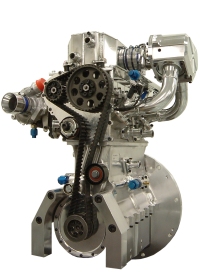

The building of the new engine is a cast cylinder head, a machined solid cylinder block and separate electrically powered oil and water pumps. Two overhead camshafts operate the conventional coil spring valve gear with the camshaft for the 4-stoke cylinders running at one half crankshaft speed and the fifth stoke cylinder’s camshaft running at crankshaft speed. The engine is also turbocharged to increase the engine rating. The entire construction uses current manufacturing technology as well.

The payoff is in the early results. From 700cc peak power is 130 bulk horsepower @ 7000 rpm with torque up to 166 newton meters @ 5000 rpm using a paltry 226 grams of fuel per kilowatt hour.

Ilmor says the prototype is up and ready for road testing and could be used as a conventional engine or as part of a hybrid drive train. The company says it is “keen” a British term expressing a strong motivation, to find a partner to help develop the engine and it is talking to automakers and top suppliers about the technology.

It all sounds very good. Racing has for decades led the way in improvements in automobile technology and a new engine seems to be a logical step. Over time it may be possible for internal combustion engine builders to stay in the market of converting fuels to work. That race is really about thermodynamic efficiency, and Ilmor seems to get it.

Out there in the wilderness are other designs that offer mechanical scavenging of heat and thermal expansion to get more work per fuel molecule. One example is Kazimierz Holubowicz, a physicist skilled in quantum electrodynamics that has designed an engine that recycles the hot gasses multiple times. It’s a design known to run as well.

But this time it’s Ilmor Engineering, Roger Penske, Honda and others. While the basic invention comes from a lone inventor, it takes this level of skills, management and connections to get further along. From the press releases over the past few months on automobile model announcements calling out electric drive, a hybrid generator’s engine is of supreme interest.

As we saw last week from Professor Burke at UC Davis, the hybrid power needed will be low horsepower and very high efficiency. For the littlest engines its going to get very interesting to see what engines mate to what generators or alternators for hybrid drive trains. Ilmor might be just in time or simply to late.

Comments

54 Comments so far

Eh?

Check Wiki (or any other reference…you’ll see same)

Ilmor motor, 226g/kw-hr (0.37 lb/hp-hr)

Best efficient production auto otto

225 g.kw-hr (0.37)

Wright R-3350 compound aero engine from 1940

0.4 lb/hp – hr

VW V8 Turbo Diesel (yr 2000),

205 g/kw-hr, (0.33)

Audi 2.5 l TDI, 198 g/kw-hr

Volvo diesel truck engine,

188 g/hp-hr

Because of the expense and complexity, and because there is no demonstrated fuel efficiency advantage, I would say the Ilmor motor is a dead end.

JPS

i cant see how it would work the fact that driving another cam shaft takes energy and using burnt gases in a low cmpression cylinder dosnt add up what about vibrations or are you using counter balance weights to compensate stil they use energy ?

My cousin recommended this blog and she was totally right keep up the fantastic work!

i cant able to know the working of the engine………….

Plz explain the strokes and thermal cycle.

nice but still can be made better.

if need futher guide contact to my address

five stroke engene fuel and the losses in engene are maxm> a

I would like to say “wow” what a inspiring post. This is really great. Keep doing what you’re doing!!

can i get seminar ppt on this topic ? plz mail me.

Of course, what a great site and informative posts, I will add backlink – bookmark this site? Regards, Reader

[…] concept, the creation of the first diesel engine that was built in 1897 by Rudolf Diesel.The development of the motor car can be traced back to 1769, when a French engineer Nicolas Cugnot i…that the modern automobile is the result of over 100.000 patents at various […]

Hello, this is my first time i visit here. I found so many interesting in your blog especially on how to determine the topic. keep up the good work.

Good! Thank you! I always wanted to write in my site something like that. Can I take part of your post to my blog?

it’s good to know that 5 stroke engine soon will be on the market.But please be so kind to give the fuel consumption.Do you think it could lessen or much more than the conventional type.Thanks

sir, pleas explain the thermal cycle of 5 stroke engin is this technology is possibale in petrol engine

please sir its working explain in brief for better understanding…

can u tell wat s difference 5 stroke engines from the other engines

plz tell me it works .

plz tell me how

it works .

It’s good to know that 5 stroke engine soon will be on the market.plz tellm me it works.

tats really agood1….

sir plz difine the work and Plz tell working cycle

sir, i need for cycle… And working principle..

Its ok but please send me the detail working principle with actual calculation and drawing.Really it is a revolution.

.Very nice that engine i am very impressive this engine that peak power very surpise it. And h.p. 130 very good. Wow…….

Plz. Sir proper detail in the engine. I am gain proper knowledge in this engine.

Send us blue prints

douglassmith.seton@gmail.com

that was amazing….

i want jobs anywhere

i want jobs anywhere

Rotor Root Engine2 – two combustion chamber RRE2

Power per 1 kg weight of the engine ” power density” – 110 kwt/kg.

None of the crankshaft, pistons, valves, camshaft.

Absence of friction only rolling friction

No lubrication system, clutch, gearbox.

Uses compressed air, gasoline, diesel fuel, bio-fuel and gas.

Working in water and underwater conditions with no atmosphere.

I have developed a design of RRE2, and centrifugal compressor for air and gases. a complete set of drawings.

I am looking for partners for prototyping, testing and implementation.

Plez define its working &diff b/w 5 strok and other engine

Deficiencies and disadvantages of piston engines

1. A full cycle of a four-stroke piston engine consists of two full turns of the crankshaft, of which only one half of one turn comprises the power stroke (the only part of the whole cycle that produces any useful work). The other one and a half turns of the crankshaft the piston engine functions as a compressor.

2. More than half of the thermal energy released in the combustion process inside the cylinder is wasted in the beginning of the power stroke. Maximum pressure (Pmax) in the combustion chamber is achieved at the beginning of the power stroke when the combustion takes place (which is right after spark ignition in the gasoline engine, or right after fuel injection in a diesel engine).

At this point, the piston is located at the upper dead center (UDC, see the drawing), with the lever (R) responsible for the creation of the moment of rotation (M) being equal to zero. And since R = 0, it also follows that the moment, M = Pmax x R, is also equal to 0.

Half a power stroke later (after 90° turn of the crankshaft), the cylinder pressure drops from its maximal value down to its intermediate point (Pmid, somewhere b/w Pmax and atmospheric pressure). At this point, lever R is at its maximum, (Rmax) and, therefore, M = Pmid x Rmax.

90° to 180° is what remains of the power stroke, during which both the pressure (P) and the lever (R) drop, providing little, if any, useful work. Much of the released thermal energy is lost on heating the piston and cylinder walls.

3. Piston engines achieve their maximal rotational moment (M) only at midrange of the RPM ranges. Reasons for this are many-fold:

(a) Insufficient filling up of the cylinder with air at low RPM;

(b) Insufficient filling up of the cylinder with air at high RPM;

(c) Inertial loading of valve mechanisms and resultant loss of kinematic linkage due to the inability of valve springs to close valves fast enough at higher RPM.

As a result of the above, fuel consumption is high, engines run hot, air pollution is high, and much power is lost.

Above-mentioned peculiarities of piston engines require the use of gearbox/transmission, starter, etc. The Roots Rotary Engine (RRE) design being offered should have none of the above disadvantages or deficiencies. It requires neither a crankshaft nor a camshaft, nor pistons, valves, intake manifold, transmission/gearbox, etc. Read our patent application at US PTO: Internal combustion engine with direct air injection, or see it at any other patent search and/or listing website, such as at http://www.google.com/patents/US20120285415, http://www.freepatentsonline.com/y2012/0285415.html, etc.

Plz mail a ppt on this for a seminar

plz mail mi its ppt for seminar plZzzzzzz

plz mail mi its pdf for knowledge purpose plZzzzzzz

what is the number of revolutions of the crankshaft?

explain valve timing diagram, difference b/w 5 strokes and other strokes!

plz mail me ppt of this engine.

what is the effect on performance parameter of this engine.

Hi, Neat post. There is an issue along with your web site in internet explorer, could check this?

IE nonetheless is the marketplace leader and a good section of people will leave out your magnificent writing because of this problem.

can u plsss send me a p.p.t

of five stroke engine & i was interested to prepare it

if u dont have any objection

send me how to prepare a model of five stroke engine

Very nice …

Plz mail me on this seminar ppt…

i cant know how it works ,the pictures of working can be shown more eiffently

sir

could you please send me ppt about 5 stroke engine with detailed their cycles

my email :

kshafi1994@gmail.com

thankyou

sir,please provide me the blueprints

if you could, can u please also send me the ppt of this engine?

sir, can you send me more information about it? here is my email id vishvambhar96@gmail.com thank you

Could u pls send me ppt regarding 5-s ic engine…?

The concept is good but I have a doubts about,

1) Does engine is capable of working in all conditions? If means explain me how it works in different conditions?

2) what about vibrations and cooling?

3) what about consumption rate of fuel by the engine? Regarding loads, Weight capacity and roads condition ?

4) I want to know working cycle?

5) what’s the advantage of 5 stroke engine over a present 4 stroke engine?

6) Explain me about the exhaust system and in detail of exhaust gases with their percentage?