Jan

9

A Monolithic Foldable Battery Electrode Developed

January 9, 2020 | Leave a Comment

With the launch of wearable devices and smartphones that require high capacity of electricity such as foldable phones and 5G phones, the interest in batteries is increasing and various battery types are getting developed.

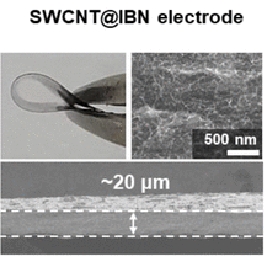

POSTECH’s foldable battery electrode Three views, life size, 500 nm, ~20 µm. Image Credit: Pohang University of Science & Technology. Click image for the largest view.

For example, think of flexible batteries embedded in the mobile watch band or wireless power sharing batteries that have developed from wireless charging systems. However, there is no manufacturing of a battery that produces a battery with thousands of milliamp Hour (mAh) capacity that can be foldable. Now a research team from Korea has developed a monolithic electrode that can replace heavy copper collectors and enables the development of a flexible battery with high capacity.

Professor Soojin Park of Chemistry and Division of Advanced Materials Science with his postdoctoral researcher, Jaegeon Ryu and his PhD student, Jieun Kang successfully developed a flexible battery with a thin and three-dimensional organic electrode in collaboration with Korea Institute of Materials Science.

The team was able to lower the weight of a battery to a tenth of the conventional copper collector by using a three-dimensional copper collector. Instead of using a graphite anode, they utilized organic materials and were able to increase the energy density of a battery by four times and more.

Their research achievement report has been published in a recent issue of ACS Nano.

Electrical conductivity of an organic material is low and there was no solution to integrate collector and an organic material. For this reason, it had not been possible to demonstrate a monolithic electrode with organic materials before their study. The research team studied a new way to replace a current collector that makes a battery heavy and a graphite anode with low energy density in order to innovatively lower the weight of battery.

The team produced a three-dimensional structure with high electrical conductivity by using single-walled carbon nanotube (SWCNT) aerogels. Then they constructed thin monolithic organic electrodes by coating a nanometer-scale imide-based network (IBN)2) organic material.

The three-dimensional monolithic electrodes coated with 8nm thin and adjustable thick organic IBN layers delivered capacity of up to 1550 mA h g-1 and it was possible to recharge it more than 800 times. These electrodes were coated with organic materials.

Despite of their poor intrinsic electrical conductivity, the electrodes had high electrical conductivity and they also demonstrated improved the electrochemical performances of the rechargeable battery by helping fast transfer of lithium through abundant redox-active sites. Moreover, thickness of coated organic materials can be controlled easily and they were able to greatly improve current density of organic electrode.

The newly developed electrode can replace the metal-based collector and this enables development of light and flexible rechargeable battery which later can be applied to wearable electronic devices, flexible devices, telecommunication and electronic vehicles of the next generation.

Professor Soojin Park who led the research commented, “We can lower the weight of a rechargeable battery enormously by using this newly developed monolithic electrode with SWCNT organic materials. This can overcome the limitations of the conventional rechargeable battery and can realize flexibility and weight lightening of an organic battery.

The march to better more versatile batteries is really getting going strong. It will be interesting to see how many make it to commercial viability and just how much they improve our relationship with personal electrical devices.