Nov

20

Engineering a Much Better Lithium Metal Battery

November 20, 2018 | 1 Comment

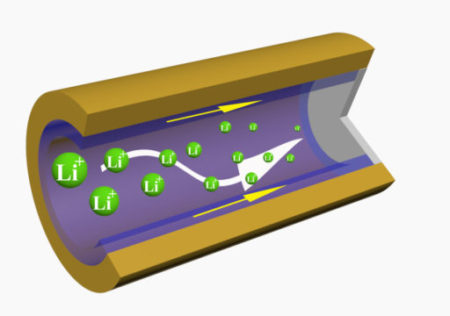

Described in Nature Energy the researchers developed a three-dimensional, cross-linked polymer sponge that attaches to the metal plating of a battery anode.

A three-dimensional cross-linked polymer sponge attaches to the metal plating of a lithium ion battery anode, allowing ion transfer and limiting deterioration. Image Credit: Donghai Wang, Penn State University. Click image for the largest view.

Donghai Wang, professor of mechanical engineering and the principal investigator of the project said, “This project aims to develop the next generation of metal batteries. Lithium metal has been tried in batteries for decades, but there are some fundamental issues that inhibit their advancement.”

Under additional strain, like in the fast-charging methods desired in electrical vehicles, lithium ion (Li) batteries are vulnerable to dendritic growth – needle-like formations that can reduce cycle life and potentially cause safety issues – including fires or explosions.

“Our approach was to use a polymer on the interface of Li metal,” Wang explained. The material acts as a porous sponge that not only promotes ion transfer, but also inhibits deterioration.

“This allowed the metal plating to be free of dendrites, even at low temperatures and fast charge conditions,” he said.

Wang, who is an affiliated faculty member at the Penn State Institutes of Energy and the Environment, also belongs to the Battery Energy and Storage Technology Center, a leading research institute in energy storage.

A critical component of both IEE and the BEST Center’s mission, this project brought together researchers from different disciplines within the University.

“The collaboration in this cohort really helped drive this paper forward,” Wang explained. “It allowed us to examine the different aspects of this problem, from materials science, chemical engineering, chemistry, and mechanical engineering perspectives.”

In this collaborative work, Long-Qing Chen’s group in the Department of Materials Science and Engineering conducted modeling work to understand the improvement of Li metal anodes.

The practical applications of this work could enable more powerful and stable metal battery technologies integral to everyday life, according to the researchers.

“In an electric vehicle, it could increase the range of a drive before needing a charge by hundreds of miles,” said Wang. “It could also give smartphones a longer battery life.”

Looking to the future, the team will explore the practical applications in a large-format battery cell to demonstrate its advantages and feasibility.

Wang said, “We want to push these technologies forward. With this work, I’m positive we can double the life cycle of these Li metal batteries.”

Your humble writer sure hopes Wang has a major win. Here the outside temperatures make the lithium ion smartphone battery a short day device unless carried inside the coat. One isn’t seeing batteries of any kind developing full energy output. The electric vehicles are driven only from heated garage to heated location or risk getting stranded.

The low temperature assistance from this technology will be much more than welcome. If the temperature levels are low enough and the performance high enough electrification could get a very large boost.

Comments

1 Comment so far

Always interested in new battery tech,

especially if it applies to mobile.

I would respectfully request the “humble writer”,

to do some investigation on how many electric

vehicles that do NOT go from heated garage to

heated station actually get stranded due

to lack of energy.

Range anxiety is virtually non existent and to

add that “alarmist” comment was unnecessary.

But I guess that is what writers do.