Feb

18

An Artificial Leaf Process Makes Isopropyl Alcohol

February 18, 2015 | Leave a Comment

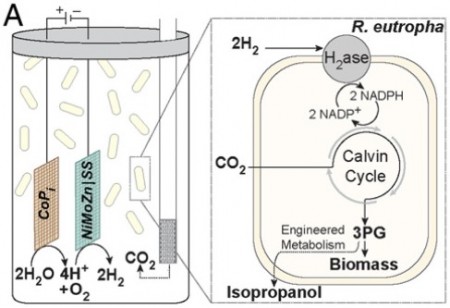

The work integrates an “artificial leaf,” which uses a catalyst to make sunlight split water into hydrogen and oxygen, with a bacterium engineered to convert carbon dioxide plus hydrogen into isopropanol.

Schematic diagram of bioelectrochemical cell. Click here to go to the PNAS paper for full details.

The team is reporting the process enables production of the fusel alcohol isopropanol at up to 216 mg/L, the highest bioelectrochemical fuel yield yet reported by more than 300%.

Pamela Silver, the Elliott T. and Onie H. Adams Professor of Biochemistry and Systems Biology at HMS and an author of the paper, calls the system a bionic leaf, in a nod to the artificial leaf invented by the paper’s prolific senior author, Daniel Nocera, the Patterson Rockwood Professor of Energy at Harvard University. The co-first authors are Joseph Torella, a recent PhD graduate from the HMS Department of Systems Biology, and Christopher Gagliardi, a postdoctoral fellow in the Harvard Department of Chemistry and Chemical Biology.

Silver, who is Core Faculty at the Wyss Institute said, “This is a proof of concept that you can have a way of harvesting solar energy and storing it in the form of a liquid. Dan’s (Nocera) formidable discovery of the catalyst really set this off, and we had a mission of wanting to interface some kinds of organisms with the harvesting of solar energy. It was a perfect match.”

Silver and Nocera began collaborating two years ago, shortly after Nocera came to Harvard from MIT. They shared an interest in “personalized energy,” or the concept of making energy locally, as opposed to the current system, which in the example of oil means production is centralized and then sent to gas stations. Local energy would be attractive in the developing world.

“It’s not like we’re trying to make some super-convoluted system,” Silver said. “Instead, we are looking for simplicity and ease of use.”

In a similar vein, Nocera’s artificial leaf depends on catalysts made from materials that are inexpensive and readily accessible. “The catalysts I made are extremely well adapted and compatible with the growth conditions you need for living organisms like a bacterium,” Nocera said.

In their new system, once the artificial leaf produces oxygen and hydrogen, the hydrogen is fed to a bacterium called Ralstonia eutropha. An enzyme takes the hydrogen back to protons and electrons, then combines them with carbon dioxide to replicate – making more cells.

Next, based on discoveries made earlier by Anthony Sinskey, professor of microbiology and of health sciences and technology at MIT, new pathways in the bacterium are metabolically engineered to make isopropanol.

Brendan Colón, a graduate student in systems biology in the Silver lab and a co-author of the paper explained, “The advantage of interfacing the inorganic catalyst with biology is you have an unprecedented platform for chemical synthesis that you don’t have with inorganic catalysts alone. Solar-to-chemical production is the heart of this paper, and so far we’ve been using plants for that, but we are using the unprecedented ability of biology to make lots of compounds.”

The team’s immediate challenge is to increase the bionic leaf’s ability to translate solar energy to biomass by optimizing the catalyst and the bacteria. Their goal is 5% efficiency, compared to nature’s rate of 1% efficiency for photosynthesis to turn sunlight into biomass.

“We’re almost at a 1% efficiency rate of converting sunlight into isopropanol,” Nocera said. “There have been 2.6 billion years of evolution, and Pam and I working together a year and a half have already achieved the efficiency of photosynthesis.”

This group has made quite a leap with an artificial leaf that might well be part of a home or small business fuel production device. There is a long way to go, but as a comparison American corn ethanol produces something like a bit over 9 gallons of ethanol per square yard per year and sugar cane much more. If Nocera and the team get to 5% solar efficiency, solar energy would be a very different thing than what we think of now.

One of these days Professor Nocera is going to hit one out of the park.