Sep

23

A Solution for Solar Cell Power Conversion Efficiency

September 23, 2014 | Leave a Comment

University of Massachusetts Amherst (UMass) scientists have developed a more efficient, easily processed and lightweight solar cell that can use virtually any metal for the electrode, effectively breaking the “electrode barrier.” Polymer scientists and synthetic chemists have been working for decades to improve the power conversion efficiency of organic solar cells. The effort has been hampered by the inherent drawbacks of commonly used metal electrodes, due their instability, susceptibility to oxidation and other issues.

UMass’s Thomas Russell, professor of polymer science and engineering describes a barrier that has bedeviled research, “The sun produces 7,000 times more energy per day than we can use, but we can’t harness it well. One reason is the trade-off between oxidative stability and the work function of the metal cathode.” Work function relates to the level of difficulty electrons face as they transfer from the solar cell’s photoactive layer to the electrode that delivers the power to a device.

Russell likes to use a lock-and-dam analogy to talk about electron transfer. “People have thought you’d need to use tricks to help electrons, the water in the lock, over an obstacle, the electrode, like a dam. Tricks like sawing the dam apart to allow the flow. But tricks are always messy, introducing a lot of stuff you don’t need,” he says. “The beauty of the solution reached by these synthetic chemists is to just move the dam out of the way, electronically move it so there is no longer a difference in energy level.”

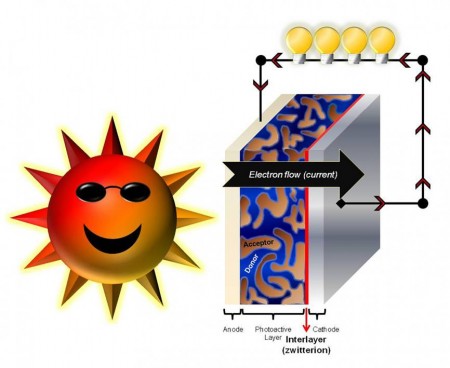

Synthetic chemist and polymer science professor Todd Emrick agrees, “That challenge was unmet and that’s what this research is all about.” He and polymer chemistry doctoral student Zak Page in his lab had been synthesizing new polymers with zwitterions on them, applying them to several different polymer scaffolds in conjugated systems, also known as semiconductors, in the inter-layer of solar cells. Zwitterions are neutral molecules with both a positive and negative charge that also have strong dipoles that interact strongly with metal electrodes, the scientists found.

Zwitterion Assisted Photo Cell. Click image for the largest view. Image Credit: Todd Emrick, University of Massachusetts Amherst.

Emrick asked Page to see if he could synthesize conjugated polymers, semiconductors, with zwitterionic functionality. With time, and by enlisting a system of multiple solvents including water, Page was able to prepare these new “conjugated polymer zwitterions,” or “CPZs”.

Emrick explains, “Once we could make CPZs, we were able to incorporate any conjugated backbone we wanted with zwitterionic functionality. That allowed us to make a library of CPZs and look at their structure-property relationship to understand which would be most important in electronics. In particular, we were interested in electron transport efficiency and how well the CPZ could modify the work function of different metals to help move electrons across interfaces towards more powerful devices.

Page explained that in choosing a metal for use as an electrode, scientists must always negotiate a trade-off. More stable metals that don’t degrade in the presence of water and oxygen have high work function, not allowing good electron transport. But metals with lower work function (easier electron transport) are not stable and over time will degrade, becoming less conductive. That pulls out the power generated with resistance shedding the energy out as heat.

Page was guided by UMass Amherst’s photovoltaic facility director Volodimyr Duzhko in using ultraviolet photoelectron spectroscopy (UPS). Page categorized several metals including copper, silver and gold, to identify exactly what aided electron transport from the photoactive layer to the electrode. Page and Emrick found that “if you want to improve the interlayer properties, you have to make the interface layer extremely thin, less than 5 nanometers, which from a manufacturing standpoint is a problem,” he said.

To solve the problem Page and Emrick began to consider a classic system known for its good electron transport: buckyballs, or fullerenes, often used in the photoactive layer of solar cells. “We modified buckyballs with zwitterions (C60-SB) to change the work function of the electrodes, and we knew how to do that because we had already done it with polymers,” Page pointed out. “We learned how to incorporate zwitterion functionality into a buckyball as efficiently as possible, in three simple steps.”

That’s when the synthetic chemists turned to Russell’s postdoctoral researcher Yao Liu, giving him two different fullerene layers to test for electron transfer efficiency: C60-SB and another with amine components, C60-N. From UPS analysis of the zwitterion fullerene precursor, Page suspected that the amine type would enhance power even better than the C60-SB variety. Indeed, Liu found that a thin layer of C60-N between the solar cell’s photoactive layer and the electrode worked best, and the layer did not have to be ultra-thin to function effectively, giving this discovery substantial practical advantages.

Page said, “That’s when we knew we had something special.”

Emrick added, “This is really a sweeping change in our ability to move electrons across dissimilar materials. What Zak did is to make polymers and fullerenes that change the qualities of the metals they contact, that change their electronic properties, which in turn transforms them from inefficient to more efficient devices than had been made before.”

Russell offered, “Their solution is elegant, their thinking is elegant and it’s really easy and clean. You put this little layer on there, it doesn’t matter what you put on top, you can use robust metals that don’t oxidize. I think it’s going to be very important to a lot of different scientific communities.”

This could be a major manufacturing step into the future. Electrical junctions such as soldered connections, must number in the trillions across the world’s electronic and electrical device fleet. If the research leads to a new connection method that reduces resistance, power needs would be reduced, labor costs cut back and the toxicity of electronic waste would go down as well. Lets hope the research goes on to join the full array of electrical connections and some work includes the mechanical strength aspect as well.