Aug

28

Old Tires Become New Lithium Battery Parts

August 28, 2014 | Leave a Comment

Oak Ridge National Laboratory (ORNL) scientists have found a way for recycled tires to see new life in lithium-ion batteries. By modifying the microstructural characteristics of carbon black, a substance recovered from discarded tires, a team is developing a better anode for lithium-ion batteries.

The team led by Parans Paranthaman and Amit Naskar is developing a better anode for lithium-ion batteries. An anode is a negatively charged electrode used as a host for storing lithium during charging.

Paranthaman said, “Using waste tires for products such as energy storage is very attractive not only from the carbon materials recovery perspective but also for controlling environmental hazards caused by waste tire stock piles.”

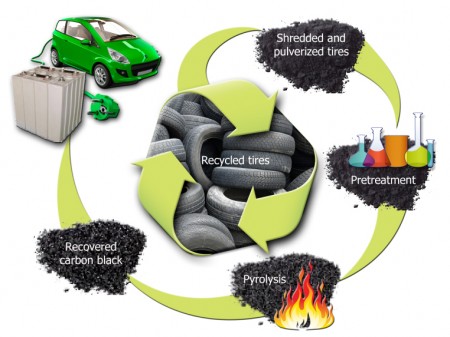

The ORNL technique uses a proprietary pretreatment to recover carbon black material, in a morphologically tailored pyrolysis process, which is similar to graphite but man-made. When used in anodes of lithium-ion batteries, researchers produced a small, laboratory-scale battery with a reversible capacity that is higher than what is possible with commercial graphite materials.

The surprising result is after 100 cycles the capacity measures nearly 390 milliamp hours per gram of carbon anode, which exceeds the best properties of commercial graphite. Researchers attribute this to the unique microstructure of the tire-derived carbon.

“This kind of performance is highly encouraging, especially in light of the fact that the global battery market for vehicles and military applications is approaching $78 billion and the materials market is expected to hit $11 billion in 2018,” Paranthaman said.

Naskar noted anodes are one of the principle battery components, with 11 to 15 percent of the materials market share and that the new method could eliminate a number of hurdles.

“This technology addresses the need to develop an inexpensive, environmentally benign carbon composite anode material with high-surface area, higher-rate capability and long-term stability,” Naskar said.

ORNL plans to work with U.S. industry to license this technology and produce lithium-ion cells for automobile, stationary storage, medical and military applications. ORNL has posted the solicitation titled, “Low-Cost, Graphite Anodes For Lithium-Ion Batteries,” in FedBizOpps (www.fbo.gov). The solicitation (#ORNL-TT-2014-08) closes Sept. 15. Other potential uses include water filtration, gas sorption and storage.

The technology ideas for lithium-ion batteries keeps on coming. So fast that commercial integration is a difficult challenge. This idea could well get to scale as the recycling product would have a high value added to the other products from recycled tires. Maybe one day recyclers will pay us to get old tires inside of us paying them to take the tires away.