Jun

18

Norway is kicking off at full speed to develop drilling tools that will make it profitable to exploit true geothermal heat. The SINTEF Foundation at the Norwegian University of Science and Technology is leading a group of industrial and technology companies led by Alexandre Kane in a research project called Nextdrill.

Kane, a research scientist said, “What we have done so far is no more than to scratch the surface of the Earth. The heat that many people extract from their gardens and then upgrade in heat pumps is not geothermal, but rather solar energy.”

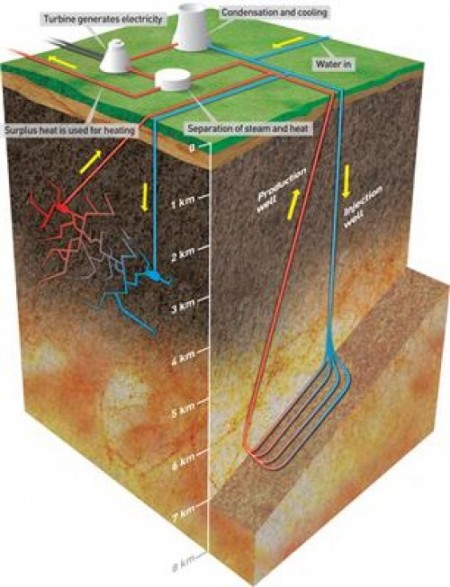

The first goal is impressive. The group’s immediate aim is to drill wells to depths of five to six kilometers (16,400 to 19,685 feet), where temperatures are encountered that are high enough to allow the heat to be used for district heating and electricity generation.

Kane explains, “For this to be commercially viable we will need to drill much more cheaply than the petroleum industry does, and without needing permanent subsidies. At the same time, we need to penetrate bedrock that is much harder than we find on the continental shelf in the North Sea. It may sound as though it will be impossible to do both of these things at once, but we have a great belief in the possibility, as long as research continues along the same lines after this preliminary project has come to an end.”

The Norwegian group definitely has the handle of the problems in hand.

As in all drilling operations, the “taximeter” of expenses rises rapidly. If geothermal heat is to be competitive as a source of energy, the time put into drilling must be kept to a minimum. Drilling operators who want to capture this heat therefore need to be able to drill at high speed. Nor can they afford the loss of time involved if the drill-bit is always having to be brought to the surface, replaced and returned to the bottom of the hole.

The Nextdrill project is a response to this challenge. Three of its members – SINTEF, the Swedish company Sandvik and Germany’s H.C. Starck – are collaborating on the development of materials for a drill bit with a long working life.

Another participant is the Norwegian technology company Resonator, which is in the process of developing an electric percussion rotary drill, a tool that crushes rock by dealing it hammer-like blows as the drill-bit turns. Electrical operation offers the possibility of remote control and more energy-efficient drilling systems than technology based on today’s pneumatic or hydraulic systems.

For those readers with experience in drilling with a standard drill and a hammer drill the possibilities the Norwegians could exploit may finally put deep geothermal into a competitive framework.

During this the rest of this year the Nextdrill project will carry out its first small-scale drilling trials near Ås in Akershus County. In August and again in November, a specially designed version of Resonator’s percussion rotary drill will tackle hard rock. It will be fitted in turn with commercially available drill-bits and bits made of the highly wear resistant materials that are being developed by the project.

The Nextdrill project is developing materials that will give drill-bits an extremely long useful life. The project uses materials such as tungsten carbide and cobalt. Tungsten carbide is extremely hard, and will protect the drill-bit against wear. Cobalt is a hard brittle metal that absorbs energy from impacts.

These trials have two main purposes. They will provide new knowledge about how wear occurs on drill-bits when rock is crushed using an electric percussion rotary drill. The tests will also show how the number of impacts per unit of time affects the speed of drilling.

“Although we will not be drilling very deep during these tests we do expect to gather important data for the next stages of our efforts to develop highly durable materials,” said Kane.

Here is a little background. The heat that SINTEF wants to capture is known as geothermal energy, and is derived from two sources that lie far beneath our feet. About one third of it is heat that has been stored in the Earth’s molten core since our planet was formed. The other two-thirds have their origin in the decay of radioactive isotopes in the Earth’s crust. This process releases heat, which means that the temperature rises, meter by meter, the further one drills into the interior of the planet.

Two types of well need to be drilled to exploit the heat; one to pump cold water down, and the other to bring hot water up again. (See the illustration above).

The drill-bit that does this job must be able to crush hard rock types such as granite. The main aim of the Nextdrill project is to identify a combination of hard-wearing, durable materials and technical solutions that can do this.

Kane expands. The drill-bit needs to be able to withstand a high level of friction, in addition to enormous amounts of mechanical abuse resulting from the high-frequency hammer impacts.

“Laboratory trials and virtual experiments performed by computer models have taught us a great deal about drilling through granite, and have enabled us to develop models that we use to find the optimal form and composition of the drill-bit. The drilling trials at Ås will give us measurements that will let us further improve the computer model,” says Kane.

The Norwegian group is sure to make progress. As they note though, this is just a start. It is not a simple matter to drill miles into granite.

That leaves the other problem, the concerns about making the fractures deep down that some expect will cause earthquakes and other nasty events. Your humble writer is pretty suspicious of such ideas as the drilling is nowhere near deep enough or energy intensive enough to cause or make an “earthquake”. That’s not to say the effort to create the water passage ways aren’t going to shift, crack and move some rock.

Its difficult to image the amount of energy needed to set off a genuine earthquake. But some diesel driven pumps, water and sand aren’t going to get very far. They will shake things up, but an earthquake? Its a PR problem, one that will need dealt with.