Mar

22

Progress With a New Idea on Getting the Sugar From Biomass

March 22, 2013 | 1 Comment

Ionic liquids are the current leading edge of research to get the tough to get sugars from cellulosic and lignin tissues of plants. News has broken via a prepublication release of a paper from a team at the Joint BioEnergy Institute (JBEI). The JBEI team at the Lawrence Berkeley National Laboratory has developed a novel one-pot process to extract sugars liberated from biomass in aqueous ionic liquid (IL) solutions.

The new process is described in an open access paper in the journal Biotechnology for Biofuels. The new approach could potentially significantly reduce costs of sugar production from lignocellulose by eliminating the need for costly enzymes and decreasing the water consumption requirements. So far JBEI hasn’t offered a press release.

Ionic liquids are basically molten salts with melting points below 100 °C, the boiling point of water. A lot of recent research and development efforts for cellulosic biofuels have explored a two-step bioconversion process where step 1 is liberation of fermentable sugars from lignocellulose and then conversion of sugars into fuels and/or chemicals by fermentation. It sounds fairly simple. Getting the sugars out for fermentation has been a multi-decade struggle.

Getting the sugars and other monomers from cellulosic biomass out for conversion at low cost is one of the major challenges to the cost-effectiveness of cellulosic pathways to make biofuels.

The use of ionic liquids as biomass solvents is an attractive alternative for the pretreatment of lignocellulosic biomass that releases the sugars for making fuels. Previous research has shown that pretreatment with imidazolium-based ionic liquids can greatly accelerate the subsequent enzymatic hydrolysis of biomass, or that ionic liquids can be used with acid catalysts to liberate the sugars without having to resort to enzyme driven conversions.

Using the ILs can be made to work that far, but the next step of separation of the sugars from the IL, as well as an effective means to recover and recycle the IL, also pose their own economic and sustainability challenges.

The JBEI team reports their process uses the phase separation behavior of imidazolium ILs of alkali/water solutions in tandem with acid catalyzed hydrolysis to extract the sugars liberated from biomass from the aqueous IL solutions. The new approach offers the potential of reducing costs of sugar production from lignocellulose by eliminating the need for enzymes and decreasing the water consumption requirements of more traditional IL pretreatment approaches.

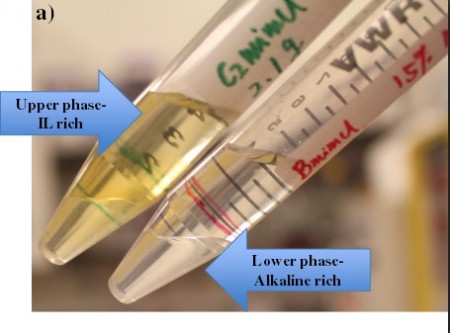

The process starts with the mixing of milled switchgrass with the IL, followed by acid hydrolysis. That produces biomass sugars in an aqueous ionic liquid solution. The addition of NaOH (sodium hydroxide, an alkaline solution) induces the formation of the biphasic system: a bottom, sugar-rich phase, which is neutralized for fuel synthesis; and a top IL-rich phase that is recycled back to the pretreatment system.

For the results reported in the paper the team has achieved maximum yields of 53% of the glucose and 88% of the xylose recovered in the alkali phase, based on the amounts present in the initial biomass.

The team is working through different temperatures finding better production at higher temperatures from the glucose.

The innovation is the team has focused more on alkaline ILs rather than only the acids. They’ve progressed far enough that partition coefficients of glucose and xylose between the IL and alkali phases can be accurately predicted using molecular dynamics simulations.

Being a two-event process in one tank so to speak, or “biphasic” the new process may well be the route of choice for separating the sugars and recycling the working chemicals.

The team shows relatively high yields without the need for any enzymes, the aqueous biphasic system enables simultaneous recovery of the sugars and IL, and the water needed is reduced.

The problems remaining aren’t simple. Removing the remaining biomass in the IL rich phase needs figured out. Then the alkaline rich phase needs the alkali salts removed for compatibility with the downstream fermentation microbes.

They may well get it done. If they do, then the vast supply of lignin and cellulosic products that could be fuel may well get to the fuel market.

Comments

1 Comment so far

Great post. I was checking constantly this blog and I

am impressed! Extremely useful information specifically the last part

🙂 I care for such information a lot. I was seeking this particular info for a

very long time. Thank you and best of luck.