Dec

17

A Practical Way to Use Expensive Platinum

December 17, 2012 | 1 Comment

A research group at the National Institute of Standards and Technology (NIST) has developed a method of depositing ultrathin layers of platinum atoms on a surface. Using a revised method of electrodeposition that’s relatively simple, fast and effective the team achieves the highly desired uniformity. Uniformity offers greatly reduced costs of the platinum and improves the catalytic surface’s reactivity.

The NIST’s new process exploits an unexpected feature of electrodeposition of platinum – if you drive the reaction much more strongly than usual, a new reaction steps in and shuts down the metal deposition process, allowing an unprecedented level of control of the platinum film thickness.

Laying down platinum uniformly is a challenging problem. NIST’s research model system deposits a platinum layer on gold. A voltage is applied to drive the deposition of platinum from an electrode onto the gold surface in an aqueous solution.

Normally, this leads to a patchy and rough surface rather than the desired smooth and even layer of platinum, because platinum tends to attach first to any defects on the gold surface, and then tends to attach to itself, rather than the gold.

The NIST team found the unexpected feature by increasing the voltage, the driving force of the reaction, far higher rates than normal. The voltage rate was taken to the point where the water molecules start to break down and hydrogen ions form, leading to an unexpected and useful result.

The hydrogen quickly forms a layer covering the freshly deposited platinum islands and completely quenches further metal deposition.

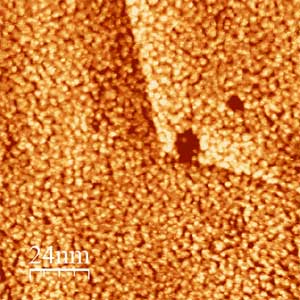

Using a battery of analytic techniques, including a quartz crystal microbalance, X-ray photoelectron spectroscopy and scanning tunneling microscopy, the group found that the formation of the hydrogen layer was rapid enough to restrict deposition to the formation of a single layer of platinum atoms. The team further discovered that by pulsing the applied voltage, they could selectively remove the hydrogen layer to enable the platinum deposition process to be repeated to form another layer.

The deposition process occurs in a single plating bath and is surprisingly fast – 1,000 times faster than making comparable films using molecular beam epitaxy, for example. It’s also faster, simpler and less prone to contamination than other electrochemical techniques for depositing platinum films, making it much less expensive.

The researchers believe the new technique may also work with a number of other metal and alloy combinations, which is a subject of ongoing research. The team’s paper has been published in Science.

Platinum is a rare element, and quite expensive, so materials engineers try to use it as sparingly as possible as a thin layer on a substrate. They’d like to be able to control the deposition process down to uniform, single layers of atoms. So far platinum hasn’t been very cooperative. Now there looks like cause for some relief in the expense.

Thin layers of platinum are quite common. Platinum is a widely used industrial catalyst, its in automobile catalytic converters and the leading catalyst in hydrogen fuel cells. It’s also a key component in microelectronics, so the discovery may have widespread application in the design and manufacture of platinum-based devices.

We’re using it in very small amounts more than we realize. The NIST’s work looks like a route to even better lower cost applications that should lead to ever more efficient devices and some deices that for now are not economically viable.

Its very good news.

Comments

1 Comment so far

This is exactly the kind of discovery that makes you wonder why no one thought of it before?