Nov

5

Getting Ready for a Rotating Detonation Engine

November 5, 2012 | Leave a Comment

U.S. Navy is always looking for ways to improve the fuel consumption of gas-turbine engines for propulsion and electric power generation. Naval Research Laboratory (NRL), scientists are studying the complex physics of Rotating Detonation Engines (RDEs) which offer the potential for high dollar savings by way of reduced fuel consumption in gas-turbine engines.

Current gas-turbine engines are attractive because they scale well to larger power, are relatively small and self-contained, and are relatively easy to maintain. Gas-turbines are based on the Brayton thermodynamic cycle, in which air is compressed and mixed with fuel, combusted at a constant pressure that expands to do work for either generating electricity or propulsion.

NRL researchers believe that one attractive possibility is to use the detonation cycle instead of the Brayton cycle for powering a gas-turbine. NRL has been on the forefront of this research for the last decade and has been a major player in developing Pulse Detonation Engines (PDEs). The RDE is an even more attractive and different strategy for using the detonation cycle to obtain better fuel efficiency. NRL researchers have constructed a model for simulating RDEs using earlier work done on general detonations, as a foundation.

NRL researchers believe that RDEs have the potential to meet 10% increased power requirements as well as 25% reduction in fuel use for future Navy applications.

Before we start on the technology we’ll use some imprecise terms for simplicity and clarity. The Brayton cycle is a slow reaction, fuel burns. In an energy production process oxygen and a fuel are mixed, compressed, ignited and burned creating a quick but steady pressurized gas to convert the reaction energy to mechanical work. A detonation is a fast reaction; the fuel explodes. In an energy production process oxygen and fuel are mixed and initiated to a detonation event exploding the mixture creating a near instantaneous high gas pressure. That’s where the technology kicks in.

Detonations have long been associated with explosions not with engines. Detonations produce extremely high pressures, shock waves, and high-velocities. Another difficulty for engine applications is repeatedly generating detonations consistently and efficiently.

Research over the last several decades on materials that are able to withstand the high pressures, temperatures, and heat fluxes associated with detonations, and on initiators that are efficient, fast, and reliable, have made detonation engines a possibility.

A Brayton cycle turbine relies on a multistage compressor in order to increase the pressure of the air from atmospheric to a higher pressure. Detonations, on the other hand, are close to a constant volume reaction process, and naturally generate high pressures that can then be expanded to do work without any compressor at all.

Much simpler compressors can be used to generate the equivalent efficiency. Adding a compressor to a detonation engine increases the efficiency further, so technology developed for Brayton cycle engines can still be used for detonation engines.

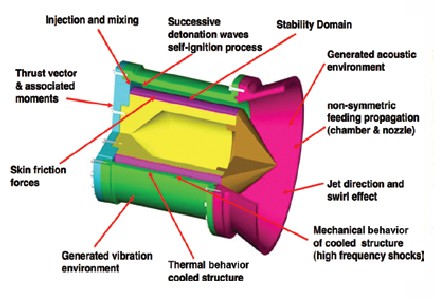

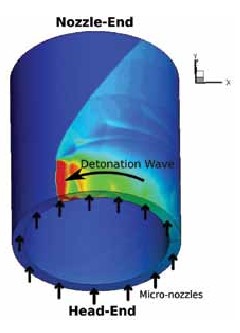

An RDE takes a new approach toward realizing the efficiency of the detonation cycle. By allowing the detonation to propagate azimuthally around an annular combustion chamber, the kinetic energy of the inflow can be held to a relatively low value, and thus the RDE can use most of the compression for gains in efficiency, while the flow field matches the steady detonation cycle closely.

An RDE is illustrated above. The combustion chamber is an annular ring, in which the mean direction of flow is from the injection end (bottom in the graphic) to the exit plane (top). A series of micro-nozzle injectors introduce a premixture of fuel and air or oxygen axially from a high-pressure plenum, and a detonation propagates circumferentially around the combustion chamber, consuming the freshly injected mixture. The gas then expands azimuthally and axially, and can be either subsonic, supersonic or both, depending on the backpressure at the outlet plane. The flow has a very strong circumferential aspect due to the detonation wave propagation. Because the radial dimension is typically small compared to the azimuthal and axial dimensions, there is generally little variation radially within the flow. Because of this, the RDE is usually “unrolled” into two dimensions, and NRL does this for many simulations with small thickness-to-diameter ratios.

The Rotating Detonation Engine (RDE) is an even more attractive and different strategy than Pulse Detonation Engines for using the detonation cycle to obtain better fuel efficiency. NRL researchers have constructed a model for simulating RDEs using earlier work done on general detonations, as a foundation.

As with Pulse Detonation Engines RDEs have the potential to be a disruptive technology that can significantly alter the fuel efficiency of ships and planes; however, there are several challenges that must be overcome before the benefits are realized, explains Dr. Kailasanath, head of NRL’s Laboratories for Computational Physics and Fluid Dynamics. NRL scientists are now focusing their current research efforts on getting a better understanding of how the RDE works and the type of performance that can be actually realized in practice.

Many Navy aircraft use gas-turbine engines for propulsion and the Navy depends on gas-turbine engines to provide propulsion and electricity for many of its ships. Even as future ships move toward the model of an “all electric” propulsion system, they will still need gas-turbine engines to produce electricity for the propulsion system and other critical systems.

Using extensive simulations over a wide range of conditions, the NRL has been able to form a picture of how performance is affected by different common engine parameters and sizing parameters. Continued work in this area will help to further understand the performance envelope of these engines and to develop experimental test rigs and eventually functioning engines.

There’s a lot of money to save. Currently there are about 430 gas turbine engines on 129 U.S. Navy ships that burn approximately 2 billion dollars worth of fuel each year. By retrofitting these engines with the rotating detonation technology the NRL researchers estimate that the Navy could save approximately 300 to 400 million dollars a year.

Go Navy!