Aug

22

Mechanical Energy to a Battery in One Step

August 22, 2012 | 1 Comment

The technology eliminates the need to convert mechanical energy to electrical energy for charging a battery. Its more efficient, a hybrid generator-storage cell utilizes mechanical energy more efficiently than systems using separate generators and batteries.

Wang estimates that the self-charging power cell will be as much as five times more efficient at converting mechanical energy to chemical energy than a two-step generator-storage system.

Wang compares the present with the potential saying, “People are accustomed to considering electrical generation and storage as two separate operations done in two separate units. We have put them together in a single hybrid unit to create a self-charging power cell, demonstrating a new technique for charge conversion and storage in one integrated unit.”

Central to the self-charging power cell is a piezoelectric membrane that drives lithium ions from one side of the cell to the other when the membrane is deformed by mechanical stress. When deformed the lithium ions driven through the polarized membrane by the piezoelectric potential are directly stored as chemical energy using an electrochemical process.

Supported by the Defense Advanced Research Projects Agency (DARPA), the U.S. Air Force, the U.S. Department of Energy, the National Science Foundation, and the Knowledge Innovation Program of the Chinese Academy of Sciences the research is in the current issue of the journal Nano Letters.

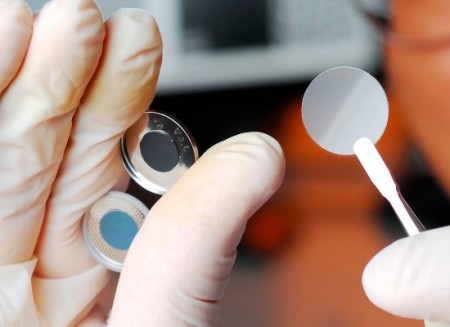

The self-charging power cell consists of a cathode made from lithium-cobalt oxide (LiCoO2) and an anode consisting of titanium dioxide (TiO2) nanotubes grown atop a titanium film. The two electrodes are separated by a membrane made from poly(vinylidene fluoride) (PVDF) film, which generates a piezoelectric charge when placed under strain. When the power cell is mechanically compressed, the PVDF film generates a piezoelectric potential that serves as a charge pump to drive the lithium ions from the cathode side to the anode side. The energy is then stored in the anode as lithium-titanium oxide.

Charging occurs in cycles. First, the compression of the power cell creates a piezopotential that drives the migration of lithium ions until a point at which the chemical equilibrium of the two electrodes are re-established and the distribution of lithium ions can balance the piezoelectric fields in the PVDF film. Then, when the force applied to the power cell is released, the piezoelectric field in the PVDF disappears, and the lithium ions are kept at the anode through a chemical process.

To complete the cycle an electrochemical process oxidizes a small amount of lithium-cobalt oxide at the cathode to Li1-xCoO2 and reduces a small amount of titanium dioxide to LixTiO2 at the anode. Compressing the power cell again repeats the cycle.

To get the electricity, a load is connected between the anode and cathode, the electrons flow to the load, and the lithium ions within the cell flow back from the anode side to the cathode side.

The team used mechanical compressive force at a frequency of 2.3 Hertz, increasing the voltage in the power cell from 327 to 395 millivolts in just four minutes. The device was then discharged back to its original voltage with a current of one milliamp for about two minutes. The researchers estimated the stored electric capacity of the power cell to be approximately 0.036 milliamp-hours.

These folks are serious; so far the team has built and tested more than 500 of the power cells. So far much of the mechanical energy applied to the cells is consumed in deforming the stainless steel case the researchers use to house their power cell. Wang understands using an improved case would boost the power storage.

Wang explains, “When we improve the packaging materials, we anticipate improving the overall efficiency. The amount of energy actually going into the cell is relatively small at this stage because so much of it is consumed by the shell.”

In the context of using the self-charging power cell the cell should also greatly reduce weight and space required by separate generators and batteries.

If there is enough energy in something moving to deform the membrane energy can be harvested. The list is immense beyond the obvious walking, vehicle suspensions, ocean waves, wind, sound, and many, many more.

Wang is still cautious; the technology isn’t factory ready. But the idea has legs, its simpler, smaller and inevitably will be cheaper than most charging procedures now. The current prototype the self-charging power cell generates enough current to power a small calculator. The hunt is on.

Comments

1 Comment so far

Your means of describing all in this post is actually nice, every one be capable of

effortlessly know it, Thanks a lot.