May

19

A New Way to Get Hydrogen From Water

May 19, 2011 | 1 Comment

Monash University of Australia in the lead role with researchers at UC Davis in the USA and using the facilities at the Australian Synchrotron has published a paper the journal Nature Chemistry Sunday May 15, 2011 describing very simple mineral, commonly seen as a black stain on rocks that oxidizes the oxygen out of water. It’s not a new idea, but the research team thinks they may have the start of a viable commercial process.

Professor Leone Spiccia at the School of Chemistry at Monash says the ultimate goal of researchers in the field is to create a cheap, efficient way to split water, powered by sunlight, which would open up production of hydrogen as a clean fuel, and leading to long-term solutions for our renewable energy crisis.

The team’s effort has been studying complex catalysts designed to mimic the catalysts plants use to split water with sunlight. But the new study shows that there might be much simpler alternatives at hand.

Professor Spiccia comes right to the point saying, “The hardest part about turning water into fuel is splitting water into hydrogen and oxygen, but the team at Monash seems to have uncovered the process, developing a water-splitting cell based on a manganese-based catalyst (based on Birnessite). Birnessite, it turns out, is what does the work. Like other elements in the middle of the Periodic Table, manganese can exist in a number of what chemists call oxidation states. These correspond to the number of oxygen atoms with which a metal atom could be combined.”

The process prompts a bit of astonishment. The manganese in the catalyst cycles between two oxidation states: first, the voltage is applied to oxidize from the manganese-II state to manganese-IV state of birnessite. Then in the sunlight the birnessite goes back to the manganese-II State.

This cycling process is responsible for the oxidation of water to produce oxygen gas, protons and electrons.

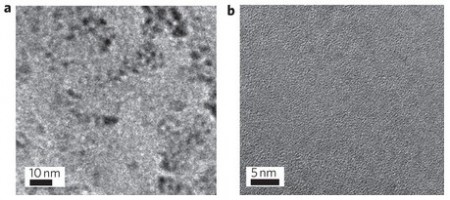

Professor Spiccia explains, “When an electrical voltage is applied to the cell, it splits water into hydrogen and oxygen and when the researchers carefully examined the catalyst as it was working, using advanced spectroscopic methods they found that it had decomposed into a much simpler material called birnessite, well-known to geologists as a black stain on many rocks.”

Co-author on the research paper, Dr. Rosalie Hocking, Research Fellow in the Australian Centre for Electromaterials Science explained that what was interesting was the operation of the catalyst, which follows closely natures biogeochemical cycling of manganese in the oceans.

“This may provide important insights into the evolution of Nature’s water splitting catalyst found in all plants which uses manganese centers,” Dr Hocking said.

“Scientists have put huge efforts into making very complicated manganese molecules to copy plants, but it turns out that they convert to a very common material found in the Earth, a material sufficiently robust to survive tough use.”

The technical explanation is almost too short. The reaction has two steps; first, two molecules of water are oxidized to form one molecule of oxygen gas (O2), four positively-charged hydrogen nuclei (protons) and four electrons. Second, the protons and electrons combine to form two molecules of hydrogen gas (H2). Simple enough . . .

Put your birnessite out in the sun and make a catalyst, put the catalyst in water and apply an electric charge to produce hydrogen and then put the used catalyst back in the sun to get your catalyst back.

Seeing the process in the instruments seems to have set up the discovery. The experimental work was conducted using state-of-the art equipment at three major facilities including the Australian Synchrotron, the Australian National Beam-line Facility in Japan and the Monash Centre for Electron Microscopy, and involved collaboration with Professor Bill Casey, a geochemist at UC Davis.

Dr. Hocking said, “The research highlights the insight obtainable from the synchrotron based spectroscopic techniques – without them the important discovery linking common earth materials to water oxidation catalysts would not have been made.”

The big questions, such as the efficiency of the catalyst vs. electrolysis or the recycling times the catalyst can withstand aren’t answered, yet. But the science here is getting to a process much more akin to what plants use for freeing the atoms in water. There is good reason think that following on this research could lead to much less costly ways to get the hydrogen freed from water.

The H2O bond is a tough one, but better analysis and some vision on where to look has found a payoff that could be a jumping off point to a lower cost hydrogen source. Its not as simple as electrodes in water with some current, but if the electricity demand is greatly reduced, an over night production with a daylight catalyst recovery doesn’t seem like too much of a barrier.

The financial funding flow looks like something that may have staying power with the U.S. Department of Energy, the U.S. National Science Foundation adding to and backing the funds from Monash University, the Australian Research Council through the Australian Centre of Excellence for Electromaterials Science, and the Australian Synchrotron.

It might be more than just a very worthy investment. There’s a long way to go, but this is something to keep an eye on.

Comments

1 Comment so far

I really think that this is great) information that you guys are sharing on your site. So many times I visit sites of people who really don’t know what their talking about. Thanks for sharing pure value and giving your audience great content!