Apr

19

A New Way to Produce Hydrogen

April 19, 2011 | 5 Comments

A research team at Ecole Polytechnique Fédérale de Lausanne (EPFL) in Switzerland has announced they have come upon a new catalyst for electrolysis to split hydrogen out of water. In a serendipitous moment the team led by Xile Hu made this discovery during an electrochemical experiment. Hu said, “It’s a perfect illustration of the famous serendipity principle in fundamental research. Thanks to this unexpected result, we’ve revealed a unique phenomenon.” Being alert has rewards when lightning strikes, thanks to Professor Hu and his group the new hydrogen catalyst has been found.

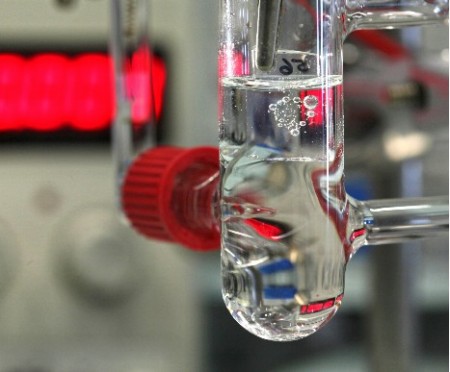

Molybdenum Based Water Splitting Catalyst Working on the Lab Bench. Click the press release link at the beginning of the post for more quite large photos.

Splitting hydrogen is an energy expensive process. For industrial use most hydrogen is extracted using heat for the energy and sources such as natural gas with more easily cracked apart molecular bonds. Cheap free hydrogen is a dream of energy nirvana for many, but as a practical matter having cheap hydrogen sources would have a basic cost savings across a wide swath of industrial production. It’s an important breakthrough, and how low the operating costs get are important data.

Professor Hu’s team discovered that a molybdenum-based catalyst allows hydrogen production at room temperature, and is inexpensive and efficient. EPFL has already started an international patent filing based on the discovery.

The background is water is composed of hydrogen and oxygen. The water molecule can be cracked apart from flowing an electrical current between electrodes in the process known as electrolysis. As this is a slow and energy consuming reaction, platinum is generally used as a catalyst to improve the production rate. But platinum is a dreadfully expensive material that has tripled in price over the last decade.

Now EPFL scientists have shown that abundant and commercially available amorphous molybdenum sulphides are efficient catalysts and hydrogen production cost can be significantly lowered. That’s a grand statement yet the press release isn’t conveniently clear on making a comparison. What is clear is 15 mA cm−2 at η = 200 mV) will get the job done. This is not a lot of power and someone will kick in the comparative numbers.

The other significant benefit is the catalysts are stable and compatible with acidic, neutral or basic conditions of the water and the rate of the hydrogen production is faster than other catalysts of the similar price.

The discovery opens up some interesting possibilities for industrial applications. Plus it could offer a tool in the area of solar energy storage.

The catch is as with all the water splitting technologies is the hydrogen gas bubbles out along with the oxygen making oxyhydrogen gas also known as Browns Gas, a ready to ignite fuel mixture. Getting the hydrogen and oxygen separated without any possible ignition is the next step to useful electrolysis of water beyond a process that reignites the oxyhydrogen gas for the heat and pressure gain.

Its quite a breakthrough, the dam holding up hydrogen production has a trickle over the top now, a hint that splitting water is an idea that with more research might get to a lower cost industrial scale. Some engineers are already calculating if money can be saved, and the independent experimenters are likely thrilled to get an improvement over the popular stainless steel plate method.

The EPFL team has made the breakthrough. It has certainly set off a new round exploration. We’re one step closer to economical hydrogen production from water.

Comments

5 Comments so far

I have this idea. It is a cylinder of water 2000 feet high. At the bottom are electrodes, creating hydrogen and oxygen. The gas floats up through the water, turning turbines all the way, creating electricity. When they gas gets to the top, it is used to create steam and turn turbines. The idea is that the machine creates more energy than it uses.

Maybe this fantasy can be a reality with this new knowledge of molybdenum.

Question: Will this process be adaptable to placing it on an automobile and producing hydrogen on demand in quantities needed? Thereby enableing the engine to be operated solely on hydrogen from water? Also safely?

I would sincerely appreciate knowing more about this development.

There is many questions I would like to know about weather this system could produce enough brown gas to run a car by slowly shutting off the gasoline to the engine and having it runs solely on brown gas.What is the perfect PH level of water that would not only help speed up the process but help reduce the power needed to produce the brown gas.

Question : In a automotive Hydrogen on demand System, Would you need to replace all 316L Stainless Steel Plates with molybdenum plates or only the Cathodes, in order to receive all the benefits of this new recovery ? And is a electrolyte required or plain water is ok ?

Kind Regards, Peter petergrote@hotmail.com

The better manufacturers will boast a custom unique blend only

they have. The points actually protect the sharp inside curves that continue the

cut, thus the curves have less wear over time.

The design is very intuitive to operate with little or no direction required on how the lock functions.