Jun

14

A New Way to Make Carbon Fiber

June 14, 2010 | 9 Comments

Carbon fiber – it’s the current holy grail of structural material for transportation vehicles like airplanes, cars, trucks, busses and rail. Moving the person or the freight is one thing; the thing that moves them is the other. The less the moving thing weighs the more efficient and less energy required.

But carbon fiber is expensive, other than boutique scale products, only the aerospace industry has the economics to make carbon fiber practical. Graphene research might be pointing the way forward.

James Tour, professor of chemistry at Rice University explains graphene isn’t very soluble, partly because of its dimensions, and partly because of its chemistry. Graphene is just one atom thick, but its surface area is huge. “If you want to work with graphene, you’re working dilute, which makes sense, because this is a huge whopping molecule.”

The Rice University researchers have made graphene solutions 10 times more concentrated than any before. They’ve used these solutions to make transparent, conductive sheets similar to the electrodes on visual displays, and they’re currently developing methods for spinning the graphene solutions to generate fibers and structural materials for airplanes and other vehicles that promise to be less expensive than today’s carbon fiber.

Most methods for making graphene start with graphite and involve flaking off atom-thin sheets of graphene, usually using chemical means. Yang Yang, professor of materials science and engineering at the University of California, Los Angeles explains, “The key is to make single-layer graphene, to not destroy it in the process, and to do it in high volume.”

The Rice University researchers are building from know-how using carbon nanotubes. Dispersing the nanotubes in a liquid makes it possible to process them into macroscopic fibers and films. Most solvents are incapable of dispersing carbon nanotubes, but Rice group uses “superacids” such as fuming sulfuric acid and chlorosulfonic acid to disperse them at high concentrations without harming or altering the carbon nanotube sidewalls.

The late Nobel laureate Richard Smalley discovered that highly concentrated sulfuric acid, so strong it’s called a “superacid,” can bring carbon nanotubes into solution by coating their surfaces with ions.

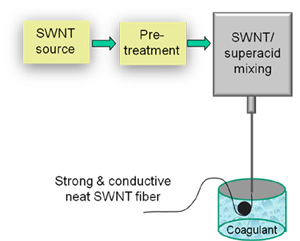

Building SWNT Fiber. Image Credit: Rice Chemical and Biomolecular Engineering. This is the largest image.

The Rice work with nanotube dispersions enabled research on the production of single walled carbon nanotube (SWNT) fibers using a method similar to that used in the industrial production of Kevlar fibers. Highly concentrated nanotube dispersions in acid can be extruded as a continuous filament; removal of the acid in a coagulant bath causes the dispersion to solidify into a solid fiber composed entirely of carbon nanotubes.

Last year, the Rice group, now led by chemist Matteo Pasquali, showed they could use superacid solutions of carbon nanotubes to make fibers hundreds of meters long. The Rice advance in making and processing graphene in solution may make it practical to work with the material at manufacturing scale. The group has successfully contracted with a major chemical company to commercialize the process in hopes of making electrical transmission lines.

Professor Tour says the superacid solution does not degrade the material’s properties. The group has used the solutions to make sheets of graphene with low electrical resistance and is now “full steam ahead” using these solutions to make graphene fibers.

Tour expects the graphene processing method to have two major applications: transparent electrodes and structural materials as it may bring down costs.

Indium tin oxide, the transparent conducting material most commonly found in touch screens and solar cells, is expensive and brittle, says Benji Maruyama, senior materials research engineer at the Air Force Research Laboratory in Ohio. The U.S. Air Force is funding the Rice research. Many groups have demonstrated the advantages of graphene electrodes in terms of conductivity and flexibility; the Rice method should make it possible to manufacture them over large areas.

Second, the process could also be used to bring down the costs of lightweight, tough structural carbon fiber materials. These materials have been around for decades, but they remain expensive because the processes used to manufacture them are complex and result in lost material. Instead of making pure carbon into fibers directly, as in the Rice process, the current process starts with a nitrile polymer fiber that’s heated to turn it into graphite. These fibers are then woven into mats and glued together to make a bulk material. “They’re used in aircraft, but not in automobiles, because the costs are too high,” says Tour. “If we can do this more cheaply and get as good or better properties, there is the potential for a real advance in carbon fibers.”

Pasquali’s group at Rice may well have a commercial scale new way to make carbon fibers and sheets of “conductive circuit boards” and conductors for visual displays. The experience of getting the nanotube process licensed bodes well for some level of commercial production for the graphene based carbon products.

The test remains getting to the economies of commercial scale such that carbon fiber is competitive with heavier materials such as steel and aluminum. Pasquali said some months back, “For transmission lines you need to make tons, and there are no methods now to do that,” he says. “We are one miracle away.”

The graphene acid solution method is looking good. Parts for very strong lightweight transport vehicles might be coming soon.

Comments

9 Comments so far

[…] the original post: A New Way to Make Carbon Fiber | New Energy and Fuel By admin | category: RICE University | tags: efficient-transportation, make-graphene, […]

Thanks very much for your wonderful website;this is the stuff that keeps me on track through my day. I have been searching around for this site after I heard about them from a buddy and was pleased when I was able to find it after searching for some time. Being a demanding blogger, I’m happy to see others taking initiative and contributing to the community. I just wanted to comment to show my support for your post as it is very enticing, and many bloggers do not get acknowledgment they deserve. I am sure I’ll be back and will spread the word to my friends.

This is a wonderful technological iluminating study, very interesting useful add value to new inventions and science.

Many thanks, wish further successes.

Couldnt agree more with that, very attractive article

Ive got to say, the layout alone made me come back to this blog again. But now that Ive read what youve got to say, Ive got to share it with the world!

This post makes a lot of sense !

Interesting read, perhaps the best article iv’e browse today. We learn everyday cheers to you!

I’ve just started off a blog, the knowledge you give on this site has aided me extremely. Thank you for all your time & work.

Intriguing post. I have been searching for some good resources for solar panels and discovered your blog. Planning to bookmark this one!