Jan

27

A Jet Turbine Engine for Your Hybrid Vehicle

January 27, 2010 | 23 Comments

A jet engine for a hybrid vehicle generator set seems at first a little extreme. But is it? The scale for jet turbines for outside observers is the huge engine hanging from the wings of airliners. That’s a little deceptive, as those jet’s turbine engines are much smaller than what’s visible. The power turbine inside is turning the big slave turbine that is so visible. The slave turbine is really a very high-speed propeller. The mass of pulled and forced air bypasses the smaller power turbine inside.

Inside is a much smaller turbine engine. These engines have seen immense improvements since the early days when the easy to recognize torpedo shape was common. Those engines worked by exhausting a hot high-speed gas flow. But a lot of energy is wasted in heat. Much energy could be recovered by mechanically connecting to the rotating shaft.

Even so, jet turbines we recognize are big. From natural gas turbines powering utility size generation sets to ship-sized turbines these are massive power engines. But little ones have been built. Some of you can remember the Chrysler automotive turbine model in the 1960s. Small turbines have come a very long way since.

A consortium led by the UK’s micro gas turbine company Bladon Jets with Jaguar Land Rover and leading electrical machine company SR Drives, has secured investment from the UK’s Technology Strategy Board to develop an Ultra Lightweight Range Extender (ULRE) for next-generation electric vehicles. That’s Brit speak for a hybrid vehicle generator set. The allure is – turbines are very tolerant about the fuel they can use.

The consortium’s objective is to produce the world’s first commercially viable – and environmentally friendly – gas-turbine generator specifically for automotive applications. Their ULRE will incorporate the Bladon Jets’ patented axial-flow gas turbine engine coupled to a high-speed generator using SR Drives’ proprietary switched-reluctance technology. Engineers at Jaguar Land Rover will oversee the design of the ULRE’s packaging and integration into vehicles.

The advantages in Bladon’s claim for small external combustion gas turbine engines are they’re more efficient, less polluting and lower cost than internal combustion reciprocating engines. Add to that gas turbine engines will run on just about any type of fuel including natural gas and bio-fuels. Turbines are not dependent on specific fuels, external combustion allows a wide range for fuel choice. Rigged for liquid fuel, a turbine could use ethanol up to heavy diesel. It’s fuel accessibility risk reducer as well.

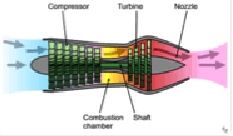

Axial Jet Engine Flow

Bladon’s specific choice in turbines is to use axial flow instead of radial flow. An axial flow turbine uses more fans to compress close to the axial shaft. That allows very high compression. A radial flow uses less fan compression with the compression increase coming from a squeeze between the extended shaft body and the outer wall. Radial flow is much less costly to build, but axial flow is much more efficient.

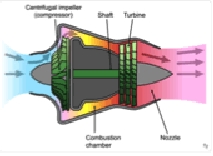

Radial Jet Engine Flow

Bladon may have answered some of the radial build advantage with a new process to manufacture the blades and hubs. Bladon is doing a full bladed hub and blades in one piece. That allows the machining to be quite precise and the singular casting is stress free at lower mass. No more assembled blades to the hubs. Plus engineering adaptations are easily accommodated in manufacturing. The surprise is Bladon is now at 75mm (just under 3 inch) rotor diameter. Now one can see the hybrid vehicle potential.

Bladon Jets 75mm Compressor Rotor

Turbine engines while expensive, might finally be cost comparable to internal combustion. The turbine won’t need the water-cooling system components, or catalytic converters and much of the emission equipment. The fuel system will be simpler; the total number of parts will be greatly reduced as well as the total weight. They warm up in just seconds saving cold start inefficiency.

The Bladon route to hybrid vehicle generation sets might just work if the costs can be driven low enough. Turbines are high-speed precision engines. Fed clean air they should last a very long time with very little attention. Keep in mind, compared to sophisticated piston engines the 5% effect applies to size, weight, part count and power output. An effective turbine HEV generator set isn’t going to be very big or heavy.

It’s all about cost. The materials are not cheap, but what power and rotational speed requirements would be needed isn’t discussed yet. Bladon has a patented technology to reduce manufacturing costs and claims they can address material from the lower cost to the most expensive. One just has to assume, the Bladon team must have the numbers to make the effort, and if they do, series hybrid designs with turbine generator sets might just really take off.

It’s very encouraging. The ability to catch an emergency fill from the cooking oil in the kitchen, or a simple kerosene fill up or ethanol or whatever might be cheapest is an alluring feature that should support the Bladon effort for quite some time.

Comments

23 Comments so far

There is a lot of merit to this concept. Jet engine technology, if I understand it correctly, is significantly more efficient than internal combustion engines are. The big downside to jet technology is that it cannot produce the dynamic power changes that the internal combustion engine can. That issue, however is addressed with hybrid technology. The battery systems provide the power dynamics, the jet engine maintains the charge in the batteries.

That said, there are a couple of other very efficient power systems that should be reconsidered now that the power range issues have been settled. The ones that come to mind are steam, and stirling cycle engines.

The Chevy volt has one thing going for it that should be considered, with modification.

With a good sized battery pack, a car should be able to confidently provide round-trip power on batteries alone. However, for long trips, an engine able to produce average consumed energy is required. I propose that the engine be removable. For short trips, the engine (turbine, steam, stirling or internal combustion) is removed. For long trips, it is mounted into place. This is the most efficent model for a universal vehicle that I can think of.

[…] This post was mentioned on Twitter by Allen Yorke and Energy Doctor, Johann Wrede. Johann Wrede said: RT @Energy4uNews A Jet Turbine Engine for Your Hybrid Vehicle | New Energy and Fuel http://bit.ly/drBlOJ: Energy4u… http://bit.ly/c4RwAc […]

[…] A Jet Turbine Engine for Your Hybrid Vehicle […]

It is a great thing to be able to use variety of fuel for Range Extension.

Looks like Bladon claims, according to the article, that Axial Compressor has more compression capacity than radial, which is a strange comment. Radial Compressors are known for their higher compression ratio and Axial compressors are generally used for high mass flow low compression ratio.

I built the CMT380. This is a sportscar that has an electric drive train (the AC150 from the Emini and licensee to Tesla), 24kwh of Kokam LiPoly batteries and a Capstone C30 Liquid Fueled Microturbine.

It currently gets between 40-50mpg on the highway at 70MPH, while haveing a 60 Miles pure EV range.

To get the Efficency up to 30% or above, you need to recooperate as much heat as possible into the intake charge. Lost heat is lost KW’s. You can use a regenerator (active component usually used with Axial Turbines) or recooperators (passive systems usually used with Radial Turbines.

Mine is more like a T34 Turbo with a combustion chamber connecting the compressor and turbine stages, with the exhaust routed through a recooperator for heat recovery.

The Turbine/EV drive have been very reliable. I have had more problems with door latches and windshields than turbines and AC drive systems.

Now there is the little thing about cost, but at 5000 units or less, the economics aren’t there yet…

I thought of this a couple of years ago after the electric versus range thing came up in a conversation at a poker game. I live in San Francisco which is very hilly so there’s a lot of energy wasted going up hills and a lot of brake wear going down. That got me thinking about the advantages of regenerative braking with an electric vehicle, and how that would be perfect for local trips.

But what about going to Santa Cruz or Death Valley? I figured a turbine could be small, light and reliable but had no idea about cost.

I also realized that using GPS systems and telling the car what you’re planning to do would help efficiency. For example it’s 506 miles from my house in SF to Furnace Creek in Death Valley. With a stop overnight in Mojave and several short stops along the way, the car can use these stops to recharge the batteries, as well as charging while driving, and GPS info would allow the car to anticipate the terrain ahead. The latter is significant considering that when approaching Death Valley from the south west via the Panamint Valley the road rises almost straight up 3,000 feet from the valley floor to Towne Pass, and then drops 5,000 feet to sea level at Stovepipe Wells in Death Valley.

If charging “meters” existed at rest stops, restaurants and motels, then that would of course reduce the need to use the generator thus saving fuel and emissions.

This certainly seems like a better way than the idea of swapping batteries.

The article in EVO Magazine on this really caught my eye. My only question though is what about the systems or accessories that currently run off of the accessory belts, vacuum, or coolant from our current internal combustion engines…

Belts running for power steering and water pump aren’t a big issue since we have electric racks now a-days, the need for an alternator would obviously be gone, and there will be no need to circulate coolant through the block because well–there is no block, so no water pump either.

However there will be a need for heat, I for one don’t want to be running around in winter without some toasty air running across my frozen hands. What would be an effective way to harness the heat produced from these little turbine engines and how are the interiors of all electric cars currently on the market heated now?

This obviously brings us the the next point, which is cooling. We obviously use accessory belts to run the ac compressor, so how would we do this with the new hybrid-car design?

The next thing would be vacuum, right now MOST cars on the road still use the conventional vacuum assisted master cylinder type brake setup. Some more recent, mostly higher end cars are using brake-by-wire electric fluid pumps instead of the master but unless I’m mistaken they still rely on some sort of vacuum from the engine. I would imagine this is a small hurtle since jet engines probably produce sufficient vacuum you can pull from.

Just curious.

I guess a little Google never hurt anybody…

Photo:

http://www.rover.org.nz/pages/jet/images/jet9c.jpg

And article it came from:

http://www.rover.org.nz/pages/jet/jet2.htm

Respectful disagreement with the above poster who mentioned a removable engine. The jet turbines are so incredibly lightweight that you wouldn’t even want to go through the effort of removing it unless it was on a motorcycle. You’re talking about a drivetrain that would have several hundred pounds of batteries, a couple hundred pounds of motor, and an engine that weighs probably less than 100. The batteries would also have to be much heavier to have an acceptable range without constant charging.

There are other unforseen consequences in terms of weight. Converting to an electric brake system is not only inherently heavier, but would have to be built in such a way that it would never lose power even if the batteries were dead. Probably a completely separate electrical system would be in order for the power brakes. And if there’s a motor at each wheel, a conventional brake system would not necessarily bolt right on. No matter how you swing it, in the short-term future, no hybrid will ever be as light as a similarly powerful internal combustion drivetrain. Batteries are just not that efficient in terms of energy to weight.

But in my opinion, the thing that would hold this product back would be the publics unwillingness to adapt to new things. The high pitched whine would scare people, people would be stupid and try to burn unsuitable fuels, either damaging the car or disrupting the peace with acrid fumes (an unintended consequence that will get the emissions czars concerned) and idiots everywhere would think of dumb reasons to hate on it. You’d literally have people filling up with nail polish remover, unfiltered frier oil, and bacon fat! I wonder how those rotors would take to unrefined animal fats..

I hope this technology sees fruition but in the short term (next 15-25 years) I see cleaner emitting rotary engines as being the future of hybrid electric powertrains. They can be built to be so tiny and with such density of power, and shoved anywhere. They’re cheap, simple, infinitely scalable, and pose no weird crash safety issues. Such a system is still significantly more efficient compared to a non-hybrid car, and that’s good enough for most people, even if a rotary engine is less efficient in terms of fuel in -> power out then any of these other technologies.

I think this jet turbine technology would be more at home in vehicles that see more extreme situations and where cost is less of an issue, like marine applications, heavy planes, trains, 4x4s that see extreme adventure, vehicles that are otherwise “off the grid”, and even heavy duty construction equipment. So I don’t have my doubts at all about the potential of this technology, but I don’t see it appearing in driveways any time soon except in halo cars. The thing that would really turn people on to this tech would be a major interruption to the conventional fuel supply.

So when and were can I buy one. I would like to use just the turbine and generator portion as a genset on my hybrid, no internal combustion, sailboat. Electric motors to drive the props powered by batteries that are charged by solar, wind and if need be Turbine.

With a twinned set of batteries and a small jet engine used only to recharge a one battery pack at a time (one pack would run the motors, while the other accepts a charge), the possible range is limited only by the gas tank size. Cooling batteries could be accomplished by the incoming air running over the batteries in the front of the car. The heating and cooling system requirements might be accomplished by recapturing the heat from the jet combustion system through a small scale steam powered system (byproduct heat!). The weight of the battery packs might seem an issue but the cabin forward design of some Dodge vehicles show that the engine compartment can be manipulated and the positioning of the batteries might enhance the low center of gravity. While everyone loves the idea of an electric sports car, I really think this is a technology better suited for the family of 5 with storage needs, going on a long vacation. I would like to see this used in a hybrid minivan constructed from lighter weight materials and using the hybrid to get the 50mpg rating to the soccer mom mobiles!

This jet engine will be loud, but I guess no louder than some of the motorcycles/ hot rods on the road. I don’t see how they can build it cheap because the materials will have to be able to withstand really high temps and pressure. The batteries alone for EV’s cost around 14,000.00…Maybe with a jet engine to recharge they could use a cheaper battery than lithium ion batteries and cut cost in that way?

Hybrid cars are really necessary these days if we want to stop pollution. ‘

Technology Submission – Novel Rotary-Turbo-InFlow Tech / Featured Development

*GEARTURBINE PROJECT:

Atypical InFlow Thermodynamic

Technology Proposal Submission

Innovative [TURBO-ROTARY]

Novel (Fueled) Motor Engine Type

-The Gearturbine comes from the contemporary ecological essential global needs of an efficient power plant fueled motor engine. -Power thrust by bar (tube); air, sea, land and power generation, work use application.

*Have the similar simple basic system of the “Aelopilie” Heron´s Steam Turbine device from Alexandria, [10-70 AD] one thousand nine hundred years ago. Because; the circular dynamic motion, with 2/Two Opposites power [polar position] lever, and is feeds from his axis center.

YouTube Video/10.30 min; * Atypical New • GEARTURBINE / Retrodynamic = DextroRPM=> VS to <=front; "Collision-Interaction Type" – inflow vs. blades-gear-move. Technical unique dynamic innovative motion mode. [Retrodynamic Reaction = When the inflow have more velocity the rotor have more RPM Acceleration, with high (XY Position) Momentum] Which the internal flow (and rotor) duplicate its speed, when activated being in a rotor (and inflow) with [inverse] opposite Turns. A very strong Novel concept of torque power thrust. At field explanatory example with a metaphor is like if a sailboat take the wind from his prow front to move; wind/inflow + knots/rpm + wind/inflow + knots/rpm + wind/inflow + knots/rpm + etc… = Acceleration x Acceleration = Exponential Acceleration. Whereas it has more movements forwards, it receives a frontal impulse still but to move more forwards. A present example of the implementation of the Retrodynamic effect is in the application in the accelerator (and collider) of particles that this in the border of Switzerland and France.

-Shape-Mass + Rotary-Motion = Inertia-Dynamic / Form-Function Wide [Flat] Cylindrical shape + positive dynamic rotary mass = continue Inertia kinetic positive tendency motion / all the complete Rotary motor mass weight is going with the power thrust move circular direction.

-Non-waste parasitic looses system for cooling, lubrication & combustion; -Lubrication & Combustion, inside a conduit radial position, out way direction, activated by Centrifugal Force-Fueled Injected. -Cooling; a) IN-Thermomix flow, & b) OUT-Air Thermo transference.

-Combustion 2Two [Inside-Rotary-Dynamic] continue circular [Rockets] flames. Like two dragons trying to bite the tail of the [ying yang] opposite other.-Increase the first compression by going of flow reduction of one big circumference blades going pass to 2TWO reduced, very long distance (total captive compression) INFLOW [inside propulsion] CONDUITS [long flow interaction] [like a digestive system] Start were ends, in perfect shape balance in perfect equilibrium well balanced, like a snake bite his own tale. -4 TURBOS Rotary [inside-rotary-active] [In-Flow, Out-Flow] Total Thrust-Power Regeneration [Complete] Power System. -Mechanical direct 2two [Small] "Planetary Gears" at polar position. Like the Ying Yang Symbol/Concept. Wide out the Rotor circumference were have much more lever [HIGH Torque] POWER THRUST. -Military benefits, No blade erosion by sand & very low heat target profile.-3 stages of inflow turbo compression before combustion; 1)1-Turbine, 2)2-Turbos 3)2-Turbos. -And 3 points of power thrust; 1-flow way, 2-gear, 3-turbine.

*The most innovative power plant motor engine project today. Higher efficient % percent. Next trend wave toward global technological coming change.

Patent; Dic. 1991 IMPI Mexico #197187 – Carlos Barrera. – Individual Designer – Inventor and project owner. / All Rights Reserved. – Monterrey NL Mexico.

YouTube Video/10.30 min; * Atypical New • GEARTURBINE / Retrodynamic = DextroRPM=> VS to <=front; "Collision-Interaction Type"

Hybrid cars will be the standard vehicle in the future

I would be interested to see what is being designed for the gear connection to the generator. Gears are often overlooked in the costings by people focussing on the primary components, there are tricky technical issues to overcome. Small turbines mean high speeds so a high speed generator would reduce the low speed torque and overall ratio. Better to use latest tech and run generator at turbine speed with no gears if it’ll hold together!

Technology Submission – State of the Art – Novel InFlow Tech – Featured Project Development; / ·1; Rotary-Turbo-InFlow Tech / – GEARTURBINE PROJECT Have the similar basic system of the Aeolipilie Heron Steam Turbine device from Alexandria 10-70 AD * With Retrodynamic = DextroRPM VS LevoInFlow + Ying Yang Way Power Type – Non Waste Looses *8X/Y Thermodynamic CYCLE Way Steps. Higher efficient percent. No blade erosion by sand & very low heat target signature Pat:197187IMPI MX Dic1991 Atypical Motor Engine Type /·2; Imploturbocompressor; One Moving Part System Excellence Design – The InFlow Interaction comes from Macro-Flow and goes to Micro-Flow by Implossion – Only One Compression Step; Inflow, Compression and outflow at one simple circular dynamic motion / New Concept. To see a Imploturbocompressor animation, is possible on a simple way, just to check an Hurricane Satellite view, and is the same implo inflow way nature.

·2-IMPLOTURBOCOMPRESSOR; One Moving Part System Excellence Design – The InFlow Interaction comes from Macro-Flow and goes to Micro-Flow by Implossion – Only One Compression Step; Inflow, Compression and outflow at one simple circular dynamic motion Concept.

*·“Excellence in Design” because is only one moving part. Only one unique compression step. Inflow and out flow at the same one system, This invention by its nature a logic and simple conception in the dynamics flow mechanics area. The invention is a wing made of one piece in a rotating motion, contained in a pair cavity system connected by implocavity, and interacting dynamically with a flow, that passes internally “Imploded” through its simple mechanism. This flow can be gas (air) or liquid (water). And have two different applications, in two different form-function; this one can be received (using the dynamic flow passage, as a receiver). Or it can be generated (with a power plant, generating a propulsion).

An example cut be, as a Bike needs a chain to work from motor to wheel. And for the Imploturbocompressor application, cut be as; in a circumstance at the engine, as an A-activate flow, and with a a tube flow conduit going to the wheel as a B-receiving-flow the work use.

To see a Imploturbocompressor animation, is posible on a simple way, just to check the Hurricane Satellite view, and is the same implo inflow way nature.

And when the flow that is received and that is intended to be used at best, must no necessarily by a exhausting or rejection gas, but must be a dynamic passing gas or liquid flow with the only intention to count it or to measure it. This could be possible at the passing and interacting period when it passes inside its simple mechanism. This can be in any point of the work flow trajectory.

In case the flow that is received is a water falling by gravity, and a dynamo is placed on the rotary bar, the Imploturbocompressor can profit an be obtained by generating? electricity such as obtained by the pelton well, like I say before. The “Imploturbocompressor”, is a good option to pump water, or a gas flow, and all kinds of pipes lines dynamic moves.

Or only receive the air-liquid flow, in order to measure its passage with a counter placed on the bar, because when this flow passes through the simple mechanism of a rotating wing made of only one piece it interacts within the implocavities system. And this flow can be air wind, with the difference of can have an horizontal work position, and that particle technical circumstances make an easy way for urban building work new use application, and have wind flow from all the sides 180 grades view. The aforementioned information about this invention refers to technical applications, such as a dynamic flow receiver. (whether being gas or liquid).

With the appropriate power plant and the appropriate dimensioning and number of RPM this invention is also feasible to generate an atmospheric air propulsion and the auto-propulsion of an aircraft. Being an effective and very simple system that implodes and compresses the atmospheric air permits the creation of a new concept of propulsion for aircrafts, due to its simple mechanism and innovative nature. At the place of the aircraft were the system appears and the manner how the propulsion direction can be oriented with a vectorial flow (no lobster tail) with I call “yo-yo system” (middle cut (at the shell) to move, one side loose), guided and balanced is feasible to create a new concept of TOVL-vertical take-off landing, Because the exhaust propulsion can going out radial in all the 360 vectorial positions, going out direct all the time in all the vectors direction. With his rotor cover for an better furtive fly, like going down of a bridge for example.

Likewise, with the due form and dimensioning, and considering the liquid density and the due revolutions for this element there could be generated a propulsion (water) in order to move an aquatic ship, whether on surface or under water. Also can be a good option to pump liquid combustion for a rocket propulsion.

Making a metaphoric comparison with the intention to expose it more clearly for a better comprehension of this innovative technical detail, it would be similar to the trajectory and motion of a dynamic flow compared with a rope (extended) that passes through the system would have now a knot (without obstructing the flow), so the complete way of the flow at the imploturbocompresor system have three direct ways and between make two different turns; direct way (entrance) – turn – direct way (implocavity) – turn – direct way (exit), all this in a 1 simple circular move system concept.

Its prudent to mention that the curves and the inclinations of the blades of a rotating wing made of this invention, is conferred by its shape and function a structural rigidity allowing it to conduct and alter appropriately the dynamic flow passing through its system. L8334 <(^_^<).

Featured Project Development: State of the Art Novel InFlowTech 1-Gearturbine RotaryTurbo, 2-Imploturbocompressor One CompressionStep: |/ *1; Gearturbine Project, Rotary Turbo, Have the similar basic system of the Aeolipilie Heron Steam Turbine device from Alexandria 10-70 AD · With Retrodynamic = DextroRPM VS LevoInFlow + Ying Yang Way Power Type – Non Waste Looses · 8X/Y Thermodynamic CYCLE Way Steps. 4 Turbos, Higher efficient percent. No blade erosion by sand & very low heat target signature Pat:197187IMPI MX Dic1991 Atypical Motor Engine Type. |/ *2; Imploturbocompressor; One Moving Part System Excellence Design – The InFlow Interaction comes from Macro-Flow and goes to Micro-Flow by Imploducted Implossion – Only One Compression Step; Inflow, Compression and outflow at one simple circular dynamic motion / New Concept. To see a Imploturbocompressor animation, is possible on a simple way, just to check an Hurricane Satellite view, and is the same implo inflow way nature. http://stateoftheartnovelinflowtech.blogspot.mx/

It’s been 9+ years since this was published, and there’s still no Bladon/UKTSVB micro-turbine power plant suitable and available for small land vehicle use.

IMHO, since the engineering and manufacturing processes have been proven for slightly larger static location applications (commercial electric power turbine-generators), the only reason for this not to have happened is prohibitive cost.

Featured Project Development – State of the Art Novel InFlowTech; ·1-Gearturbine RotaryTurbo, ·2-Imploturbocompressor One Compression Step:

*Wordpress Blog State of the Art Novel InFlow Gearturbine Imploturbocompressor:

http://stateoftheartnovelinflowtech.blogspot.mx/

*1-GEARTURBINE BEHANCE Images Gallery Portafolio:

https://www.behance.net/gallery/21019191/Novel-Rotary-Turbo-InFlow-Tech-Gearturbine-Project

-YouTube; * Atypical New • GEARTURBINE / Retrodynamic = DextroRPM VS LevoInFlow + Ying Yang Thrust Way Type – Non Waste Looses https://www.youtube.com/watch?v=0cPo9Lf44TE

·1; Rotary-Turbo-InFlow Tech / – GEARTURBINE PROJECT Have the similar basic system of the Aeolipilie Heron Steam Turbine device from Alexandria 10-70 AD * With Retrodynamic = DextroRPM VS LevoInFlow + Ying Yang Way Power Type – Non Waste Looses *8X/Y Thermodynamic CYCLE Way Steps. 4 Turbos, Higher efficient percent. No blade erosion by sand & very low heat target signature Pat:197187IMPI MX Dic1991 Atypical Motor Engine Type.

*2-IMPLOTURBOCOMPRESSOR BEHANCE Images Gallery Portafolio:

https://www.behance.net/gallery/21691891/Imploturbocompressor

·2; Imploturbocompressor; Implo-Ducted, One Moving Part System Excellence Design – The InFlow Interaction comes from Macro-Flow and goes to Micro-Flow by Implossion – Only One Compression Step; Inflow, Compression and outflow at one simple circular dynamic motion / New Concept. To see a Imploturbocompressor animation, is possible on a simple way, just to check an Hurricane Satellite view, and is the same implo inflow way nature.

+PLUS; *State of the Art, Novel Technology, Featured Project Development / Space, Satellite and Habitat, Power-Plant, Generator, Self-Feed Unit; H2O=>HHO=>H2O=>HHO=>Etc… *4 Systems All in One Unit, One By One, Plus Four-4 Projects added One to Other; *·1-Gearturbine, ·2-Imploturbocompressor, ·3-Dynamic Generator, ·4-Electrolysis System:

·1-GEARTURBINE; Rotary-Turbo-InFlow Tech,Have the similar basic system of the Aeolipilie Heron Steam Turbine device from Alexandria 10-70 AD * With Retrodynamic = DextroRPM VS LevoInFlow + Ying Yang Way Power Type – Non Waste Looses *8X/Y Thermodynamic CYCLE Way Steps. 4 Turbos, Higher efficient percent. No blade erosion by sand & very low heat target signature Pat:197187IMPI MX Dic1991 Atypical Motor Engine Type.

·2-IMPLOTURBOCOMPRESSOR; Implo-Ducted, One Moving Part System Excellence Design – The InFlow Interaction comes from Macro-Flow and goes to Micro-Flow by Implossion – Only One Compression Step; Inflow, Compression and outflow at one simple circular dynamic motion / New Concept. To see a Imploturbocompressor animation, is possible on a simple way, just to check an Hurricane Satellite view, and is the same implo inflow way nature.

·Note-Plus-This-Two Projects / to complete all the System Work:

(Self-Feed Unit Space Power-Plant-H2O=>HHO)

·3-Dynamic Generator/New Kind.

·4-Electrolysis System/BioDesign.

*(3&4-Hide-Cards-on-the-Hand).

http://stateoftheartnovelinflowtech.blogspot.mx/