Apr

22

New Fracking Idea for Geothermal and Oil and Gas

April 22, 2015 | Leave a Comment

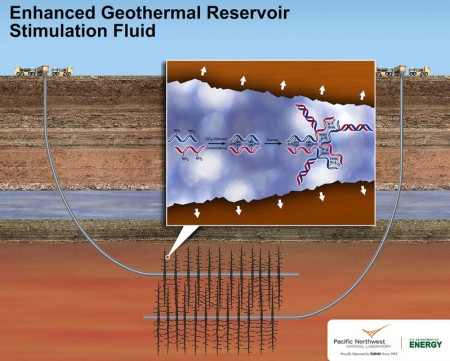

Pacific Northwest National Laboratory (PNNL) has developed a new geothermal stimulation fluid that could make geothermal power production more environmentally friendly and less costly where conventional geothermal doesn’t work. PNNL recently started a now funded study to examine a similar fluid for unconventional oil and gas recovery. The oil and gas extraction fluid being considered would use a different polyamine that is related to the chemical used in the geothermal extraction fluid.

Both fluids are stable and can withstand extreme temperatures, pressures and acidity levels.

PNNL’s geothermal fluid is a solution of water and 1 percent polyallylamine, a chemical made of a long carbon chain with nitrogen attachments that’s similar to well-understood polymers used in medicine. The fluid is pumped into a well drilled at a geothermal hot spot.

Soon after, workers also inject pressurized carbon dioxide, which could come from carbon captured at fossil fuel power plants. Within 20 seconds, the polyallylamine and carbon dioxide link together to form a hydrogel that expands the fluid up to 2.5 times its original volume.

Enhanced Geothermal Stimulation Fluid Graphic from PNNL. Pacific Northwest National Laboratory’s new geothermal stimulation fluid could make geothermal power production more environmentally friendly and less costly where conventional geothermal doesn’t work. The nontoxic fluid is designed to be used in enhanced geothermal systems, where fluids are injected into drilled wells that lead to underground geothermal reservoirs. The fluid expands when exposed to carbon dioxide underground, which creates tiny, but deep cracks in otherwise impermeable rock. Image Credit: Pacific Northwest National Laboratory. Click image for the largest view.

The swelling gel pushes against the rocks, causing existing cracks to expand while also creating new ones. The expansion is expected to cut in half the amount of water and time needed to open up an enhanced geothermal reservoir, which shrinks the cost of power generation.

The new reservoir stimulation fluid is an environmentally friendly polymer that greatly expands the fluid’s volume creating tiny cracks in deep underground rocks to improve power production. The fluid could also substantially reduce the water footprint and cost of enhanced geothermal systems.

Lead fluid developer Carlos Fernandez, a chemist at the Department of Energy’s Pacific Northwest National Laboratory said, “Our new fluid can make enhanced geothermal power production more viable. And, though we initially designed the fluid for geothermal energy, it could also make unconventional oil and gas recovery more environmentally friendly.”

To test the fluid’s performance, geophysicist and co-author Alain Bonneville led the development of an experimental set up. Five cylindrical samples of rocks, about the size of C batteries, taken near a working enhanced geothermal power plant in California, were placed inside a high-pressure, high-temperature test cell created by the PNNL team. Small amounts of the fluid and liquid carbon dioxide were injected into the test cell. Pressure and temperature were gradually adjusted to match the conditions of underground geothermal reservoirs.

The researchers found their fluid consistently created small, but effective cracks in rock samples. Some of the new fractures were too small to be seen with a high-resolution imaging method called X-ray microtomography. But when they watched fluids such as water or carbon dioxide being injected, the team saw liquids moving through the previously impermeable rock samples. Moving liquids did not pass through rock samples that were injected with plain water or the common hydraulic fracturing chemicals sodium dodecyl sulfate and xanthan gum. The team reasoned larger-scale tests might produce bigger cracks.

The new fluid gets better: Two other benefits are the fluid’s potential to be recycled and cut costs. The fluid could be recycled by reducing or stopping the fluids that are pumped underground, or by injecting an acid.

Modeling shows either would cause the hydrogel to disassemble into its original components: the water-polyallylamine solution and carbon dioxide. A pump would move the separated fluids to the surface, where they would be retrieved and used again. The fluid’s recyclability hasn’t been tested in the lab yet, however.

The operational cost of enhanced geothermal systems could also be reduced with the new fluid. With less liquid to pump underground, there will be less water to purchase, capture and treat, which lowers project costs. However, a detailed analysis is needed to precisely quantify by how much the fluid could lower enhanced geothermal’s price tag.

Additional studies are needed to further evaluate the fluid’s performance for enhanced geothermal systems. Fernandez and his team are planning lab studies to examine the fluid’s recyclability and its ability to fracture larger pieces of rock. Their ultimate goal is to conduct a controlled field test.

This is remarkable news. The team has shown a great streak of innovation here. Both the geothermal and oil and gas fracturing industries are sure to watching this, if not already thinking about how the idea can be used with other expanding compounds. A 2.5 increase in volume would have a huge effect in breaking up deep underground rock to release heat and hydrocarbons.

One could very well anticipate this technology might be one of the most important found this decade. Congratulations to the team!