Jul

22

Super Strong Metal Discovery

July 22, 2011 | Leave a Comment

PhD student Tianbo Yu at Risø DTU in Denmark has discovered a new phenomenon that will make nanometals more useful in wider use while working at the Materials Research Division at Risø. Yu has taken the research a step further in discovering the new phenomenon. The new discovery could speed up the practical application of strong nanometals. The discovery is significant enough that it has been published in the highly esteemed journal ”Proceedings of the Royal Society” in London in the form of a paper running 30 pages written by three authors from Risø DTU.

The Risø DTU press release, first reported in the U.S by Brian Wang at NextBigFuture notes super strong nanometals are beginning to play an important role in making cars even lighter, enabling them to withstand collisions without fatal consequences for the passengers. Today, the chassis and body of an ordinary automobile consists of something on the order of 193 different types of steel. The steel for each part of the car has been carefully selected and optimized. It is important, for example, that all parts are as light as possible because of the fuel consumption, whereas other parts of the car have to be super strong in order to protect passengers in a collision.

Super strong nanostructured metals are now entering the scene, aimed at making cars even lighter, enabling them to withstand collisions in a better way without fatal consequences for the passengers.

Yu’s research task was to determine the stability in new nanostructured metals, which are indeed very strong, but also tend to become softer, even at low temperatures. This is due to the fact that microscopic metal grains of nanostructured metals are not stable – a problem that Yu’s discovery now offers an explanation.

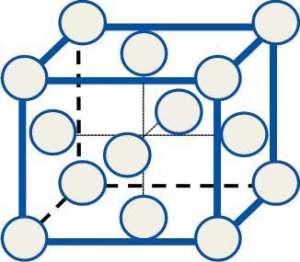

The press release explains that a fine structure consists of many small metal grains. The boundaries between these metal grains can move, also at room temperature. At the same time a coarsening of the structure takes place and the strength of the nanometal is consequently weakened. Yu has now shown that the boundaries of the grains can be locked, when small particles are present and that the solution is technologically feasible. The work explains a manufacturing process for car components to be made of nanometals.

The press release sidebar explains further. Nanometals contain very small metal grains – from 10 to 1,000 nanometers. One nanometer is a millionth of a millimeter. The smaller the metal grains become, the stronger the metal becomes. The metal becomes twice as strong, for example, if the individual metal grains are made four times smaller. That is why materials scientists work to reduce the size of the individual metal grains. In steel and aluminum, the particles have been reduced to below 1 micrometer, which is one thousandth of a millimeter. There is a great interest in nanometals and research is conducted worldwide. Nanometals are super strong and their super strength can be combined with other desired properties, too.

Nanostructured metals have been known for many years, but now they have become the subject of scientists’ renewed and strong interest. Current production examples are the thin steel wires used in grand pianos, for strengthening truck tires and specialized containers, which have to withstand an extremely high pressure.

Ms. Dorte Juul Jensen, head of Materials Research Division is happy that the excellent findings also have practical applications, “We are cooperating with a Danish company and also a Danish consulting engineering company with the purpose of developing light and strong aluminum materials with a view to their application in light vehicles where especially deformation at high rate as in a collision is the focus. The new findings will be included in this work.”

Scientists are not only interested in the size of the metal grains. The interfaces between the individual metal grains are also important to a number of properties. A special type of grain boundaries, so-called twin boundaries, provides both strength and good electrical conductivity. When that research becomes commercial for producing thinner wires, material consumption and weight will be reduced and an installation will become easier.

Expect smaller, lighter, stronger aluminum and steel, the existing prime materials across a vast array of products that will become much more efficient, safer and less bulky. All are key aspects to a more energy efficient future.