Jun

26

Virent is the Bio Fuel Producer to Beat

June 26, 2009 | 6 Comments

Virent Energy Systems is receiving one of the five 2009 Presidential Green Chemistry Challenge Awards for Small Business for its BioForming process, the water-based, catalytic method to make bio gasoline, diesel, or jet fuel from the sugar, starch, or cellulose of plants that requires little external energy beyond that of the biomass feedstock.

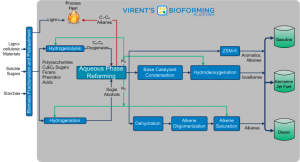

Virent’s catalytic bio forming process combines its proprietary aqueous-phase reforming technology with conventional catalytic processing technologies used in petroleum refining. The petroleum processes include catalytic hydrotreating and catalytic condensation processes, including ZSM-5 acid condensation, base catalyzed condensation, acid catalyzed dehydration, and alkylation. When combined as shown in the process chart it leads to petroleum substitutes in the same range of hydrocarbon molecules now refined from petroleum.

As with a conventional petroleum refinery, each of these process steps in the bio forming process series can be optimized and modified to produce a particular set of desired hydrocarbon products. Gasoline products can be produced using the zeolite (ZSM-5) based process, jet fuel and diesel can be produced using a base catalyzed condensation route, and a high-octane fuel can be produced using a dehydration/oligomerization route.

The Virent technique is in direct chemical contrast to biological fermentation. Virent’s process can use mixed sugar streams, polysaccharides, and C5 and C6 sugars derived from cellulosic biomass. First, water-soluble carbohydrates are catalytically hydrotreated for fractionation as a pre treatment. Next, in Virent’s APR (Aqueous Phase Reforming) process, the resulting sugar alcohols react with water over another proprietary heterogeneous metal catalyst to form hydrogen and chemical intermediates. Then the product stream is processed with one of multiple catalytic routes, which turns these chemicals into gasoline, diesel, or jet fuel components. The technology also produces alkane fuel gases and other chemicals.

The pretreatment and fractionation followed by the APR process uses more of the plant mass per acre, provides better land use and higher value for farmers. The technology needs little energy input, nearly self-sustaining, and can be completely renewable.

The gasoline to diesel fuel products are non miscible so they separate naturally from water. As a result, the process eliminates the energy-intensive alcohol distillation step to separate and collect biofuels required by other biology process technologies.

The hydrocarbon biofuels from Virent’s process are interchangeable with petroleum products, matching them in composition, functionality, and performance; they work in today’s engines, fuel pumps, and pipelines. Preliminary analysis suggests that Virent’s BioForming process can compete economically with petroleum-based fuels and chemicals at crude oil prices of $60 a barrel.

If all that’s true at scale its an award well worth the win.

Virent saw a big year in 2007. The big news was the start of collaboration with Shell Oil. Then in 2008 Virent produced more than 40 liters of biogasoline for engine testing and began fabrication of its first 10,000-gallon-per-year pilot plant to produce biogasoline. The collaboration agreement with Shell runs for five years focusing on optimizing the process for the production of gasoline like molecules.

Virent is exclusive licensee of the APR process—developed by its co-founders Dr. Randy Cortright and Dr. Jim Dumesic at the University of Wisconsin – Madison—for the conversion of readily available biomass-generated sugar feedstocks to carbon-neutral hydrocarbon fuels or hydrogen. The sugars can be sourced from non-food sources like corn stover, switch grass, wheat straw and sugarcane pulp, in addition to conventional biofuel feedstocks like wheat, corn and sugarcane. The BioForming process is Virent’s first commercial application of the APR pathway.

The BioForming process can speed the use of non-food plant sugars to replace petroleum as an energy source, thus both decreasing dependence on fossil hydrocarbons and minimizing the impact on global water and food supplies.

The BioForming platform is near commercialization. With Shell on board there is little doubt that the APR process with the refining skills will get a shot at going to commercial scale.

The Presidential Green Chemistry Challenge is now in its 14th year. Run by the Environmental Protection Agency the award promotes research and development of less-hazardous alternatives to existing technologies that reduce or eliminate waste, particularly hazardous waste, in industrial production. An independent panel of technical experts convened by the American Chemical Society selected the winners from nearly 100 nominated technologies.

That’s the leader. For this week at least. They’re claiming to be commercial at $60 oil equivalent. There’s the target.

Comments

6 Comments so far

Sharing current technology with the oil industry is positive. Oil companies will look at this as a petroleum process that just uses a differnt feedstock.

[…] will gain immediate market acceptance, is carbon neutral and uses catalysts, instead of bugs. Preliminary analysis suggests that its BioForming process is close to commercialization and can compete with petroleum […]

Keep posting stuff like this i really like it

This post makes a lot of sense !

I would like to say “wow” what a inspiring post. This is really great. Keep doing what you’re doing!!

Thanks for posting. Good to see that not everyone is using RSS feeds to build their blogs 😉