Apr

2

Ways to Improve Thermoelectric Performance Explored

April 2, 2020 | Leave a Comment

Osaka University researchers have found that thermoelectric power generators lose a great deal of their possible output power because of thermal and electrical contact resistance. Improving this limitation will help society power interconnected technologies of the future.

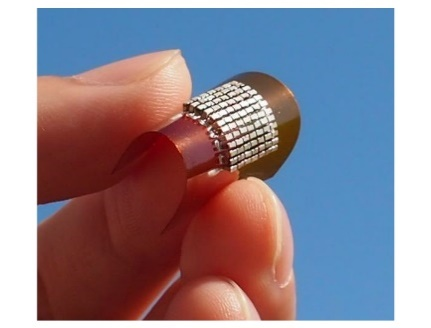

This image shows the external appearance of the developed compact, ultra-lightweight flexible thermoelectric conversion device. Image Credit: Osaka University, Click image for the largest view.

Interconnected healthcare and many other future applications will require internet connectivity between billions of sensors. The devices that will enable these applications must be small, flexible, reliable, and environmentally sustainable. Researchers must develop new tools beyond batteries to power these devices, because continually replacing batteries is difficult and expensive.

In a study published in Advanced Materials Technologies, researchers from Osaka University have revealed how the thermoelectric effect, or converting temperature differences into electricity, can be optimally used to power small, flexible devices. Their study has shown why thermoelectric device performance to date has not yet reached its full potential.

Thermoelectric power generators have many advantages. For example, they are self-sustaining and self-powered, have no moving parts, and are stable and reliable. Solar power and vibrational power do not have all of these advantages. Aviation and many other industries use the thermoelectric effect. However, applications to thin, flexible displays are in their infancy.

To date many researchers have optimized device performance solely from the standpoint of the thermoelectric materials themselves.

Tohru Sugahara, corresponding author of the study explained the team’s effort, “Our approach is to also study the electrical contact, or the switch that turns the device on and off. The efficiency of any device critically depends on the contact resistance.”

In their study, the researchers used advanced engineering to make a bismuth telluride semiconductor on a 0.4-gram, 100-square-millimeter flexible, thin polymer film. This device weighs less than a paperclip, and is smaller than the size of an adult fingernail. The researchers obtained a maximum output power density of 185 milliwatts per square centimeter. “The output power meets standard specifications for portable and wearable sensors,” said Sugahara.

However, approximately 40% of the possible output power from the device was lost because of contact resistance. In the words of Sugahara: “Clearly, researchers should focus on improving the thermal and electrical contact resistance to improve power output even further.”

Japan’s Society 5.0 initiative is aimed at helping everyone live and work together and proposes that the entirety of society will become digitalized. Such a future requires efficient ways to interconnect our devices. Technological insights, such as those by Ekubaru, co-lead author, and Sugahara, are necessary to make this dream a reality.

This research is quite welcome and is really just a start on a whole system look at thermoelectric development. Now that the team has started and the losses are revealed some thermoelectric researchers may do well to re-examine their work to see how much better their work might actually be. More news good coming one hopes.