Jan

30

New Photocatalyst Makes Syngas From CO2 and Methane

January 30, 2020 | Leave a Comment

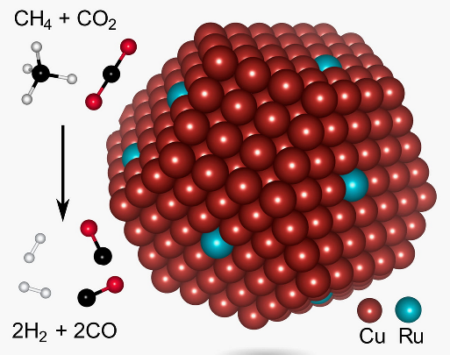

Rice University researchers boosted the stability of their low-energy, copper-ruthenium syngas photocatalysts by shrinking the active sites to single atoms of ruthenium (blue). Image Credit: John Mark Martirez/UCLA. Click image for the largest view.

The particle, tiny spheres of copper dotted with single atoms of ruthenium, is the key component in a green process for making syngas, or synthesis gas, a valuable chemical feedstock that’s used to make fuels, fertilizer and many other products. Researchers from Rice, UCLA and the University of California, Santa Barbara (UCSB), describe the low-energy, low-temperature syngas production process this week in Nature Energy.

Rice chemist and engineer Naomi Halas, a co-corresponding author on the paper said, “Syngas can be made in many ways, but one of those, methane dry reforming, is increasingly important because the chemical inputs are methane and carbon dioxide, two potent and problematic greenhouse gases.”

Syngas is a mix of carbon monoxide and hydrogen gas that can be made from coal, biomass, natural gas and other sources. It’s produced at hundreds of gasification plants worldwide and is used to make fuels and chemicals worth more than $46 billion per year, according to a 2017 analysis by BCC Research.

Catalysts, materials that spur reactions between other chemicals, are critical for gasification. Gasification plants typically use steam and catalysts to break apart hydrocarbons. The hydrogen atoms pair up to form hydrogen gas, and the carbon atoms combine with oxygen in the form of carbon monoxide. In dry reforming, the oxygen atoms come from carbon dioxide rather than steam. But dry reforming hasn’t been attractive to industry because it typically requires even higher temperatures and more energy than steam-based methods, explained study first author Linan Zhou, a postdoctoral researcher at Rice’s Laboratory for Nanophotonics (LANP).

Halas, who directs LANP, has worked for years to create light-activated nanoparticles that insert energy into chemical reactions with surgical precision. In 2011, her team showed it could boost the amount of short-lived, high-energy electrons called “hot carriers” that are created when light strikes metal, and in 2016 they unveiled the first of several “antenna reactors” that use hot carriers to drive catalysis.

One of these, a copper and ruthenium antenna reactor for making hydrogen from ammonia, was the subject of a 2018 Science paper by Halas, Zhou and colleagues. Zhou said the syngas catalyst uses a similar design. In each, a copper sphere about 5-10 nanometers in diameter is dotted with ruthenium islands. For the ammonia catalysts, each island contained a few dozen atoms of ruthenium, but Zhou had to shrink these to a single atom for the dry reforming catalyst.

Zhou explained, “High efficiency is important for this reaction, but stability is even more important. If you tell a person in industry that you have a really efficient catalyst they are going to ask, ‘How long can it last?'”

Zhou said the question is important for producers, because most gasification catalysts are prone to “coking,” a buildup of surface carbon that eventually renders them useless.

“They cannot change the catalyst every day,” Zhou said. “They want something that can last.”

By isolating the active ruthenium sites where carbon is dissociated from hydrogen, Zhou reduced the chances of carbon atoms reacting with one another to form coke and increased the likelihood of them reacting with oxygen to form carbon monoxide.

“But single-atom islands are not enough,” he said. “For stability, you need both single atoms and hot electrons.”

Zhou said the team’s experimental and theoretical investigations point to hot carriers driving hydrogen away from the reactor surface. “When hydrogen leaves the surface quickly, it’s more likely to form molecular hydrogen,” he said. “It also decreases the possibility of a reaction between hydrogen and oxygen, and leaves the oxygen to react with carbon. That’s how you can control with the hot electron to make sure it doesn’t form coke.”

Halas said the research could pave the way “for sustainable, light-driven, low-temperature, methane-reforming reactions for production of hydrogen on demand.”

“Beyond syngas, the single-atom, antenna-reactor design could be useful in designing energy-efficient catalysts for other applications,” she said.

The technology has been licensed by Syzygy Plasmonics, a Houston-based startup whose co-founders include Halas and study co-author Peter Nordlander.

Syngas is something that should make the green folks happy, it can be sourced from renewables and can be upgraded to replace fossil fuels as well as use as an industrial feedstock. But none of those routes are feasible just yet with crude oil and natural gas pricing so low.

For now though, syngas has a substantial sized market that could be exploited with this product – one that also points to way to using more renewable sources as market conditions change.