May

23

Industrial Demo Confirms Efficient Biofuel Production

May 23, 2018 | 1 Comment

Sweden’s Chalmers University researchers have developed new technologies that can be used to convert industrial plants to produce fossil-free heat, electricity, fuel, chemicals and other materials. The technical potential is enormous. By using only Sweden’s currently existing power plants, renewable fuels equivalent to 10 percent of the world’s aviation fuel could be produced.

Now, after ten years of energy research into gasification of biomass, the researchers offer an array of new technological achievements. They believe there is a chance to switch to renewable sources for heating, electricity and fuel, while also providing new opportunities for several industries to produce large numbers of renewable products.

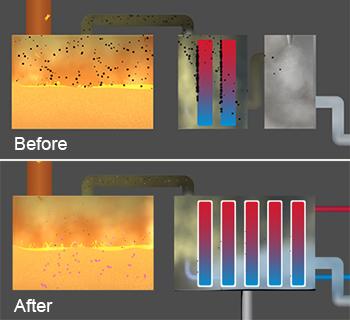

Chalmers fluidized bed gasifier handles the tar problem. Image Credit: BOID, Chalmers University of Technology. Click image for the largest view.

Henrik Thunman, Professor of Energy Technology at Chalmers said, “The potential is huge! Using only the already existing Swedish energy plants, we could produce renewable fuels equivalent to 10 percent of the world’s aviation fuel, if such a conversion were fully implemented.”

Implementing a switch from fossil-fuels to renewables is a problematic issue for many industries. For heavy industries, such as oil refineries, or the paper and pulp industry, it is especially urgent to start, because investment cycles are so long. At the same time, it is important to get the investment right because you may be forced to replace boilers or facilities in advance, which means major financial costs.

Thanks to long-term strategic efforts, the researchers at Chalmers have shown a way for radical changes, which could be applied to new installations, as well as be implemented at thousands of existing plants around the globe.

The solution they presented involves widespread gasification of biomass. This technology itself is not new. Roughly explained, what happens is that at high temperatures, biomass is converted into a gas. This gas can then be refined into end-products which are currently manufactured from oil and natural gas. The Chalmers researchers have shown that one possible end-product is biogas that can replace natural gas in existing gas networks.

Previously, the development of gasification technology has been hampered by major problems with tar being released from the biomass, which interferes with the process in several ways. Now, the researchers from Chalmers’ division of Energy Technology have shown that they can improve the quality of the biogas through chemical processes, and the tar can also be managed in completely new ways. This, in combination with a parallel development of heat-exchange materials, provides completely new possibilities for converting district heating boilers to biomass gasifiers.

Martin Seemann, Associate Professor in Energy Technology at Chalmers said, “What makes this technology so attractive to several industries is that it will be possible to modify existing boilers, which can then supplement heat and power production with the production of fossil-free fuels and chemicals.”

Professor Henrik Thunman explained the cause of such confidence with, “We rebuilt our own research boiler in this way in 2007, and now we have more than 200 man-years of research to back us up. Combined with industrial-scale lessons learned at the GoBiGas (Gothenburg Biomass Gasification) demonstration project, launched in 2014, it is now possible for us to say that the technology is ready for the world.”

The plants, which could be converted to gasification are power and district heating plants, paper and pulp mills, sawmills, oil refineries and petrochemical plants.

The Swedish Energy Agency has funded energy research and infrastructure at Chalmers for many years. The press release offered more points to consider about modifying plants:

· The facilities that could be modified have a type of combustion boiler called a fluidized bed. It is the most common technology in Swedish power and district heating plants, and is also common in many paper and pulp mills and sawmills. In total, over 100 plants in Sweden have fluidized bed boilers.

· If all of these plants were modified to biomass gasifiers, they would be able to produce 346 TWh of biogas (methane) per year, given sufficient biomass availability. This corresponds to approximately one percent of the world’s total natural gas consumption in 2013.

· Alternatively, the plants could produce 278 TWh of aviation fuel per year, equivalent to approximately 10 percent of the world’s total aviation fuel consumption in 2014.

· The biomass consumption in the above scenarios exceeds the production estimates of the Swedish agriculture and forestry industry, so a major conversion to biomass gasification would probably require a mixture of domestic and imported biomass.

· Globally, there are thousands of plants that have fluidized bed combustion, and could therefore be modified to biomass gasification.

Plus the press release offered a list about the material that can be produced:

· The technology is very flexible when it comes to end-products. Gasification of biomass produces syngas – a mixture of hydrogen, carbon monoxide and carbon dioxide – which can then be converted to a variety of hydrocarbons. In addition to biogas and aviation fuel, you can, for example, produce methanol, gasoline and diesel.

· In addition to power and district heating plants and paper-, pulp- and sawmills, the conversion could also include oil refineries and petrochemical plants. The gasification process could provide renewable hydrocarbons that can replace oil in the production of fuels, chemicals and materials. But also, it offers the possibility of supplementing their operations with their own combustion of biomass.

· The technology can also be used to produce electro fuels. These are synthetic vehicle fuels that are produced with carbon dioxide captured from biomass combustion, electricity and water. In a future energy system, with a high proportion of electricity from solar cells and wind power, it could be a method of utilizing electricity during surplus periods. An installation can be designed to switch between the production of electric fuel and other fuel, depending on the current electricity price.

· With sufficient access to biomass, the expanded production could coexist with existing production in the facilities, and provide an increased degree of utilization for today’s infrastructure.

The team’s press release also addresses the biomass availability:

There are differences in opinion over how much biomass can be produced in a sustainable way.

Göran Berndes, Professor of Biomass and Land use at Chalmers said, “My assessment is that biomass can make a significant contribution to the energy supply. But it is not enough to provide for all the applications that currently require fossil fuels. In this perspective, the conversion to gasification is very interesting, as it enables biomass to be used very efficiently to meet several different needs in society.”

Göran Berndes continued, “Regardless of how biomass is used in the end, it is important to ensure that it comes from sustainable forestry and agriculture. Laws, regulations and market-based sustainability certification schemes provide better conditions for sustainable production, but countries and individual actors differ in terms of sustainability priorities. It is therefore likely that the changeover to renewability will still be characterized by a debate regarding the sustainability of different solutions.”

The Chalmers team’s technology may well be ready for scaling up. The real task would then be at hand. Can enough money be made to incentivize the investments and risk?

There is little reason to think that compelling firms to rebuild heat and power facilities is going to work. Those that can will be located at huge sources of very cheap biomass. From forestry and farm waste then on to landfills and other urban repositories there are likely good opportunities.

There will be a few firms that closely read the published study in Energy Science & Engineering. Perhaps a few might take a crack at a new heat plant with the Chalmers design. One hopes that the Chalmers folks choose one that becomes a huge success. As nothing else will grow the new technology faster and better than success and making money.

Comments

1 Comment so far

Biofuels are no doubt a very important resource for the human now. Using it is just the implementation of keeping a sustainable development of our planet. The technologies of turning biomass into fuels will also be much more mature than before.