May

9

Tiny 3-D Lithium Ion Batteries

May 9, 2018 | Leave a Comment

Batteries might seem like they come in every shape and size that you can imagine. But as electronic devices become tinier and skinnier without reducing their power and energy demands, they challenge engineers to design batteries that can fit into smaller and smaller spaces without compromising on performance.

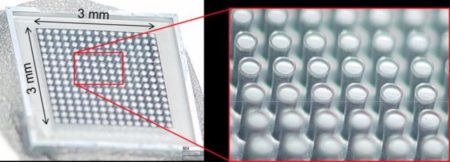

This photograph depicts the 3-D batteries developed by Janet I. Hur, Leland C. Smith, and Bruce Dunn. Image Credit: Janet Hur, UCLA.

The working group’s research paper has been published in the journal Joule.

Senior author Bruce Dunn, a professor of materials science and engineering at the University of California, Los Angeles (UCLA) said, “For small sensors, you need to re-design the battery to be like a skyscraper in New York instead of a ranch house in California. That’s what a 3D battery does, and we can use semiconductor processing and a conformal electrolyte to make one that is compatible with the demands of small internet-connected devices.”

Even the most innovative two-dimensional batteries are limited in the shapes they can take. The basic battery takes a slice of anode and a slice of cathode and packs an ion-conducting electrolyte between the two to complete the circuit. On the other hand, there are in principle innumerable ways to craft a 3D anode and a 3D cathode that snap together like puzzle pieces (still necessarily separated by a small amount of electrolyte).

The setup chosen by Dunn’s group is called a “concentric-tube” design, where an array of evenly spaced anode posts are covered uniformly by a thin layer of a photo-patternable polymer electrolyte and the region between the posts is filled with the cathode material.

Despite this apparent simplicity, many researchers have only been able to build half of a 3D battery, creating anodes and cathodes that are stable on their own, but fail when trying to assemble these electrodes into one functional battery. Meanwhile, nearly all of the 3D batteries which have been assembled have not been significantly better than ordinary two-dimensional versions.

Dunn and postdoctoral scholars, Janet Hur and Leland Smith, overcame these hurdles by taking methods normally used to make semiconductors and modifying them to carve silicon into a grid of precisely-spaced cylinders that they wanted for the anode. “That’s something the battery world just does not do,” Dunn said.

To complete the battery, they applied thin layers of electrolyte to the silicon structure and poured in a standard lithium-ion cathode material, using the anode as a mold to ensure that the two halves would fit together just right. The resulting battery achieved an energy density of 5.2 milli-watt-hours per square centimeter, among the highest reported for a 3D battery, while occupying a miniscule 0.09 square centimeter footprint and withstanding 100 cycles of charging and discharging.

Dunn notes that this particular 3D battery has not yet reached its full potential, as he hopes that he and his team can boost its energy density with further tuning of battery components and assembly. “Another challenge with batteries is always the packaging,” he adds. “You need to seal them up, keep them small, and make sure they function just as well in the real world as in the glovebox.”

One day, not so far out, there will lots of small devices feeding the internet of things concept. Many more per person that we might imagine now. That probability suggests this technology has legs and the better the batteries are, the less problematic the devices will be.