Jan

3

A New High Reported For Hydrogen Production

January 3, 2018 | 3 Comments

Ulsan National Institute of Science and Technology (UNIST) scientists have introduced the highest reported electrochemical performance in hydrogen production. The joint research team’s Hybrid-Solid Electrolysis Cell (Hybrid-SOEC) system has attracted much attention as a new promising option for the cost-effective and highly efficient hydrogen production as it shows excellent performance compared with other water-electrolysis systems.

The breakthrough has been led by Professor Guntae Kim in the School of Energy and Chemical Engineering at UNIST in collaboration with Professor Tak-Hyoung Lim of Korea Institute of Energy Research (KIER) and Professor Jeeyoung Shin of Sookmyung Women’s University.

The team’s study paper has been published in the journal Nano Energy.

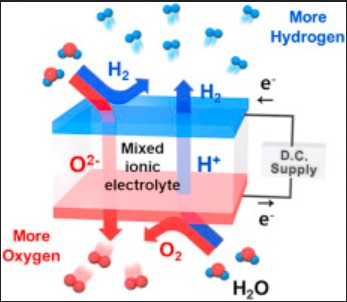

Hybrid-Solid Electrolysis Cell Process Graphic. Image Credit: UNIST. Click image for the largest view.

A solid oxide electrolyzer cell (SOEC) consists of two electrodes and an electrolyte that are all in a solid-state. These are strongly desired as new candidates for hydrogen production because they require no need to replenish lost electrolytes and eliminate the corrosion problems. Additionally the SOECs also operate at relatively high temperatures (700-1000 °C), which helps to offer reduced electrical energy consumption.

Professor Kim and his research team have been seeking ways to improve energy efficiency of hydrogen production, using a SOEC. In the study, the research team has demonstrated the novel concept of Hybrid-SOEC based on the mixed ionic conducting electrolyte, allowing water electrolysis to occur at both the hydrogen and air electrodes.

Existing SOEC electrolytes allow the transport of either only one of the hydrogen or oxygen ions to the other electrode. For the cases like the SOEC electrolytes that transport oxygen ions, water electrolysis occurs at the anode and this results in the production of hydrogen. In contrast, the SOEC electrolytes that transport hydrogen ions cause water electrolysis to occur at the cathode and this results in the production of oxygen. Here, hydrogen travels through the electrolyte to the anode.

Theoretically, using electrolytes that transport both hydrogen and oxygen ions, allows the production of two electrolysis products, hydrogen and oxygen, on both sides of the cell. This could improve the hydrogen production rate greatly. In the study, the research team paid attention to the control of properties of electrolyte.

In this study, Professor Kim and his research team reported their new findings in exploring a SOEC based on a mixed-ion conductor that can transport both oxygen ion and proton at the same time, which is denoted as a ‘Hybrid-SOEC’.

In comparison to other SOECs and representative water-electrolysis devices reported in the literature, the proposed system demands less electricity for hydrogen production, while exhibiting outstanding electrochemical performance with stability. Moreover, the Hybrid SOEC exhibits no observable degradation in performance for more than 60 hours of continuous operation, implying a robust system for hydrogen production.

Junyoung Kim who is in the doctoral program of Energy and Chemical Engineering and the first author of the study said, “By controlling the driving environment of the hydrogen ion conductive electrolyte, a ‘mixed ion conductive electrolyte’ in which two ions pass can be realized. In a Hybrid-SOEC where this electrolyte was first introduced, water electrolysis occurred at both electrodes, which results in significant increase in total hydrogen production.”

A layered perovskite with excellent electrochemical properties was used as the electrode of the Hybrid-SOEC. By adding an excellent electrode material on mixed ionic conducting electrolyte resulted in enhanced electrochemical performance. As a result, the corresponding yields of hydrogen produced were 1.9 L per hour at a cell voltage of 1.5 V at 700 °C. This is four times higher hydrogen production efficiency than the existing high-efficient water electrolytic cells.

A four fold increase in production is a very impressive result. That gain might be enough to compensate for the energy used to get the process system and water input up to an operating temperature of over 700º C.

The hydrogen production race is still on, but this is a breakout breakthrough that really raises the stakes.

Comments

3 Comments so far

We all should support such kind of research, this is good for human beings.

The hydrogen production race is still on, but this is a breakout breakthrough that really raises the stakes.

These are strongly desired as new candidates for hydrogen production because they require no need to replenish lost electrolytes and eliminate the corrosion problems.