Mar

1

Material Combines Incompatible Plastics For Recycling

March 1, 2017 | Leave a Comment

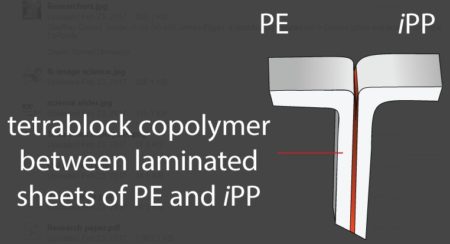

Multi Block Polymers As Adhesives. This graphic shows a welded set of polyethylene and polypropylene strips ready for a test.. Image Credit: Cornell University. Click image for the largest view.

Coates collaborated with a group from the University of Minnesota and together the team’s work is detailed in the paper “Combining Polyethylene and Polypropylene: Enhanced Performance With PE/iPP Multiblock Polymers,” published in Science. James Eagan, a postdoctoral researcher in Coates’ group, is lead author of the paper. Other collaborators included researcher Anne LaPointe and former visiting scientist Rocco DiGirolamo.

When Coates, a professor of chemistry and chemical biology at Cornell University, gives a talk about plastics and recycling, he usually opens with this question: What percentage of the 78 million tons of plastic used for packaging – for example, a 2-liter bottle or a take-out food container – actually gets recycled and re-used in a similar way?

The answer is just 2 percent. Sadly, nearly a third is leaked into the environment, around 14 percent is used in incineration and/or energy recovery, and a whopping 40 percent winds up in landfills.

A major problem is polyethylene (PE) and polypropylene (PP), which account for two-thirds of the world’s plastics, have different chemical structures and thus cannot be repurposed together. Or, at least, an efficient technology to meld these two materials into one hasn’t been available in the 60 years they’ve both been on the market.

Scientists for years have tried to develop a polymer that does what Coates, LaPointe and Eagan have achieved. By adding a miniscule amount of their tetrablock (four-block) polymer – with alternating polyethylene and polypropylene segments – the resultant material has strength superior to diblock (two-block) polymers they tested.

In their test, two strips of plastic were welded together using different multi-block polymers as adhesives, then mechanically pulled apart. While the welds made with diblock polymers failed relatively quickly, the weld made of the group’s tetrablock additive held so well that the plastic strips broke instead.

“People have done things like this before,” Coates said, “but they’ll typically put 10 percent of a soft material, so you don’t get the nice plastic properties, you get something that’s not quite as good as the original material.”

“What’s exciting about this,” he said, “is we can go to as low as 1 percent of our additive, and you get a plastic alloy that really has super-great properties.”

Not only does this tetrablock polymer show promise for improving recycling, Eagan said, it could spawn a whole new class of mechanically tough polymer blends.

“If you could make a milk jug with 30 percent less material because it’s mechanically better, think of the sustainability of that,” he said. “You’re using less plastic, less oil, you have less stuff to recycle, you have a lighter product that uses less fossil fuel to move it.”

It does look like 75 million tons of plastic could be used again, likely in a stronger product. This is a technology that offers a lot of potential. But retraining people to not throw 75 million tons of useful material away is going to be a very difficult part of the cycle.

There remains the matter of sorting. Both polyethylene and polypropylene can be individually recycled when cleared of other plastics. It would be useful for calculating how a recycler might proceed if we knew the parameters of the proportions of polyethylene and polypropylene. That leaves us with the matter of all those other plastics getting in the way.

The world makes a mountain of this stuff every year. One day we’re going to have to figure out some way to not be buried in plastic refuse.

On the other hand, plastic alloys is an intriguing idea all by itself.