Aug

26

Robot Energy Consumption Cut By Up To 40 Percent

August 26, 2015 | Leave a Comment

The Chalmers team developed a new optimization algorithm that optimizes the robot’s movements reducing acceleration and deceleration, as well as the time the robot is at a standstill since being at a standstill also consumes energy.

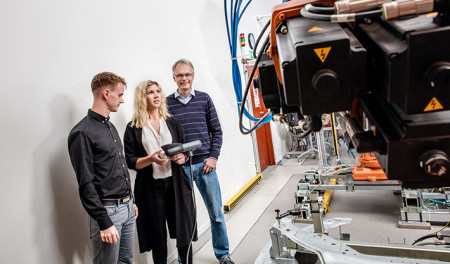

Dr Kristofer Bengtsson, master’s student Emma Vidarsson and Professor Bengt Lennartson in the Robotics and Automation Laboratory at Chalmers University of Technology. Image Credit: Oscar Mattsson, Chalmers University. Click image for the largest view.

Professor Bengt Lennartson initiated the research together with, among others, General Motors. Industrial robots are counted in the millions worldwide now and consume a substantial amount of electrical power. They range in size from huge assembly, press and weldment machines to tiny little actuators types that perform simple repetitive motions on to exacting robots that operate where humans simply cannot be such as contaminant free computer processor building.

Lennartson explained, “We simply let the robot move slower instead of waiting for other robots and machines to catch up before carrying out the next sequence. The optimization also determines the order in which the various operations are carried out to minimize energy consumption – without reducing the total execution time.”

The optimization never changes the robot’s operation path, only the speed and sequence.

“Thus, we can go into an existing robot cell and perform a quick optimization without impacting production or the current cycle,” he said.

To achieve safe optimization, several robots moving in the same area need to be coordinated. The optimization tool will therefore initially identify where robots may collide, and the entry and exit positions for each collision zone, and for each robot path.

Kristofer Bengtsson, who is responsible for the implementation of the new optimization strategy explains the next step, “The first test results have shown a significant improvement, such as a 15 to 40 percent energy reduction, but the results are still preliminary. In order to estimate the actual energy savings, further testing in industry is required.”

In robot-intensive manufacturing industries, such as bodywork factories in the automotive industry, robots consume about half of the total energy used for production.

The optimization program starts by logging the movements of each robot during an operations cycle, as well as any collision zones. This information is processed by the optimizer, which generates new control instructions that can be directly executed by the robots.

Bengtsson sums up with, “The goal is to make this kind of optimization standard, and included in robots from the start. At each adjustment of the operating sequences, a new optimization is conducted by default. But as we all know, it takes time to bring a development product into a robust production process, with several years of engineering work,”

The research group at the Department of Signals and Systems also includes PhD students Oskar Wigström and Sarmad Riazi. The optimization tool is being developed in the EU research project Areus.

Readers may have seen assembly line robot systems, they have been becoming more widespread with each passing year. They do work that is dirty, dangerous, nasty and quite unpleasant that is getting very hard to find employees to do or employ safely without huge costs.

Even if the industrial application comes in midway say at 25 to 30% the savings would be huge for what sounds like is mostly a software upgrade. One does wonder why it has taken so long for the research to have gotten underway.