Aug

26

Battery Voltage Runs Low Cost Hydrogen Production

August 26, 2014 | 5 Comments

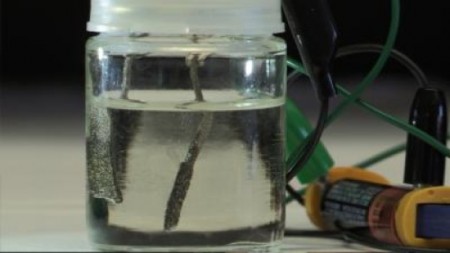

Stanford University scientists have developed a low-cost, emissions-free device that uses an ordinary AAA battery to produce hydrogen by water electrolysis. Unlike other water splitters that use precious-metal catalysts, the electrodes in this device are made of inexpensive and abundant nickel and iron.

Professor Hongjie Dai and colleagues have developed a cheap, emissions-free device that uses a 1.5-volt battery to split water into hydrogen and oxygen at room temperature. The hydrogen gas could be used to power fuel cells in zero-emissions vehicles.

The new technology could become significant as Toyota and other manufacturers plan in 2015 to offer American consumers fuel cell cars. Although touted as zero-emissions vehicles, most of the cars will run on hydrogen made from the fossil fuel natural gas.

Professor Dai explains, “Using nickel and iron, which are cheap materials, we were able to make the electrocatalysts active enough to split water at room temperature with a single 1.5-volt battery. This is the first time anyone has used non-precious metal catalysts to split water at a voltage that low. It’s quite remarkable, because normally you need expensive metals, like platinum or iridium, to achieve that voltage.”

Dai also noted that in addition to producing hydrogen, the novel water splitter could be used to make chlorine gas and sodium hydroxide, important industrial chemicals.

Splitting water to make hydrogen doesn’t necessitate fossil fuels and could emit no greenhouse gases. But scientists have yet to develop an affordable, active water splitter with catalysts capable of working at industrial scales.

“It’s been a constant pursuit for decades to make low-cost electrocatalysts with high activity and long durability,” Dai said. “When we found out that a nickel-based catalyst is as effective as platinum, it came as a complete surprise.

“The discovery was made by Stanford graduate student Ming Gong, co-lead author of the study. “Ming discovered a nickel-metal/nickel-oxide structure that turns out to be more active than pure nickel metal or pure nickel oxide alone,” Dai said. “This novel structure favors hydrogen electrocatalysis, but we still don’t fully understand the science behind it.”

The nickel/nickel-oxide catalyst significantly lowers the voltage required to split water, which could eventually save hydrogen producers billions of dollars in electricity costs, according to Gong.

The next goal is to improve the durability of the device.

“The electrodes are fairly stable, but they do slowly decay over time,” Gong said. “The current device would probably run for days, but weeks or months would be preferable. That goal is achievable based on my most recent results”

The researchers also plan to develop a water splitter than runs on electricity produced by solar energy.

“Hydrogen is an ideal fuel for powering vehicles, buildings and storing renewable energy on the grid,” said Dai. “We’re very glad that we were able to make a catalyst that’s very active and low cost. This shows that through nanoscale engineering of materials we can really make a difference in how we make fuels and consume energy.”

The new technology may be quite significant as solar power research enters the field. Its worth noting the other authors of the study are Wu Zhou, Oak Ridge National Laboratory (co-lead author); Mingyun Guan, Meng-Chang Lin, Bo Zhang, Di-Yan Wang and Jiang Yang, Stanford; Mon-Che Tsai and Bing-Joe Wang, National Taiwan University of Science and Technology; Jiang Zhou and Yongfeng Hu, Canadian Light Source Inc.; and Stephen J. Pennycook, University of Tennessee.

Driving hydrogen production costs low enough, fuel cell prices down far enough and storage systems cheap enough, could make the hydrogen enthusiasts’ dream a reality.

Comments

5 Comments so far

I would like to know the ratio of energy input vs. energy output.

Agreed. What is the ratio of energy out (ie the energy that can be produced by consuming the H2 & O2 in a fuel cell), vs. the energy provided by the the battery to run the process? This ratio would need to exceed 1.0 by a pretty good margin (because you’ll lose energy in the loop recharging batteries etc…), otherwise you’d be better off simply powering the cars directly from batteries.

Bruno, first, there’s no chance that that ratio will exceed 1.0. Second, it need not do so to be useful. Hydrogen’s energy density is far greater than that of any current battery technology. Thus, storing enough to prevent “range anxiety” is much easier with hydrogen. There are other issues, of course, such as how to store it, safety, etc. In terms of efficiency, it may be true (but it may not). It depends on the efficiency of charging and discharging the battery, the efficiency of the fuel cell, etc. Nonetheless, if hydrogen can be cheaply derived from water using renewable energy and stored for use in a fuel cell to make a vehicle with the kind of range people require, it’s a breakthrough. Further, refueling your hydrogen tank will take much less time than recharging a battery using any current technology.

Same Joe as above. What needs to be done is to have third party verification of energy input vs. output. Also, since strides have been made with regard to storing hydrogen at relative low hydrogen gas pressure, it may be possible for a car to be charged with hydrogen gas at a gas station, so-to-speak, that produces hydrogen gas on site.

I do not see how this is different to an Edison battery patented over 100 years ago. Nickel oxide and nickel as one electrode and Iron as the electrode, with KOH as the electrolyte were part of the standard Edison cell. The battery has special vents to allow for the release of HHO gas and needs to be topped up regularly with water. The Edison battery can last 40-100 years and still work. How come the Stanford invention only lasts a few days? What is the difference? Perhaps the Stanford team need to rediscover the Edison battery.