Mar

13

The Nuke The Anti Nuke Crowd Should Love

March 13, 2013 | 2 Comments

Transatomic, a Massachusetts Institute of Technology spinoff is developing a nuclear reactor designed to overcome the major barriers to nuclear power. For the anti nuclear folks the design offers to burn up the existing spent fuel from the world’s fleet of nuclear reactors in a design that doesn’t offer a chance for a meltdown. That should be nirvana for those alarmed about atomic energy and weapons proliferation.

For everyone else, the first offering is we would see a reduction in spent fuel containment costs and get electrical energy, lots of it, instead. The second is the design would be factory produced cutting build costs in a huge way and the reactors would be larger than the currently trendy Small Modular Nuclear Reactors (SMNRs) offering the chance to install at existing locations saving on the generation and grid connection costs.

Transatomic, founded by a pair of very smart and innovative young nuclear engineers, has updated the molten-salt reactor, a reactor type that’s highly resistant to meltdowns. Molten-salt reactors were demonstrated in the 1960s at Oak Ridge National Lab, where one test reactor ran for six years. What remains is raising $5 million to run five experiments to help validate the new basic design.

Russ Wilcox, Transatomic’s new CEO estimates that it will take eight years to build a prototype reactor at a cost of $200 million. The company has already raised $1 million in seed funding, including some from Ray Rothrock, a partner at the venture capital firm Venrock.

The cofounders, Mark Massie and Leslie Dewan, who we met here in April last year, are still PhD candidates at MIT. Yet the design has attracted some top advisors, including Regis Matzie, the former CTO of the major nuclear power plant supplier Westinghouse Electric, and Richard Lester, the head of the nuclear engineering department at MIT.

The new reactor design called the Waste-Annihilating Molten Salt Reactor (WAMSR) so far exists only on paper. Ray Rothrock says the company will face many challenges. “The technology doesn’t bother me in the least,” he said. “I have confidence in the people. I wish someone would build this thing, because I think it would work. It’s all the other factors that make it daunting.” We’ll get to those daunting factors in a moment.

Background – today’s conventional nuclear power plant is cooled by water, which boils at 100º C a temperature far below the 2,000° C at the core of a fuel pellet. Even after the reactor is shut down, it must be continuously cooled by pumping in water until the whole internal core apparatus is below 100º C. The inability to do that properly is what has caused the problems at troubled plants. Oddly, the nuclear industry and regulatory agencies haven’t come to realize the notion of mixing water and nuclear fuel is the dangerous matter.

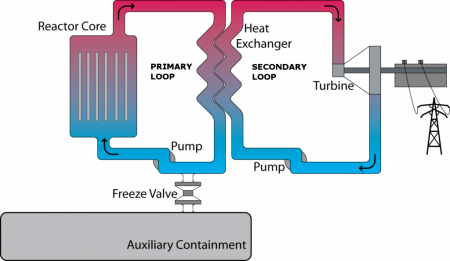

The big problems can be solved by using molten salt, instead of water as the coolant, which is mixed in with the fuel. Molten salt has a boiling point higher than the operating temperature of the fuel. That way the reactor has a built-in thermostat – if it starts to heat up, the salt expands, spreading out the fuel and slowing the reactions cooling the thing off.

In the event of a power outage where cooling circulation would stop carrying away the heat, a plug at the bottom of the reactor melts and the fuel and salt mixture flows by gravity into a holding tank, where the fuel spreads out enough for the reactions to stop. The salt then cools and solidifies, encapsulating the radioactive materials.

Ms Dewan now the company’s chief science officer says, “It’s walk-away safe, if you lose electricity, even if there are no operators on site to pull levers, it will coast to a stop.”

She needs only $5 million to prove it.

Technology – Transatomic’s design improves on the original molten-salt reactor by changing the internal geometry and using different materials. Transatomic is keeping many of the proprietary design details to itself, but one change involves eliminating the graphite that made up 90% of the volume of the Oak Ridge reactor. The company has also modified conditions in the reactor to produce faster neutrons, which makes it possible to burn most of the material that is ordinarily discarded as waste.

The design offers a couple other real strong incentives. Because it runs at atmospheric pressure rather than the high pressures required in conventional reactors the amount of steel and concrete needed to guard against accidents is greatly reduced. The technical approach will work for uranium or for the future thorium fuels as well.

Here is the comparison that should light up the hearts of the antinuclear crowd. A conventional 1,000-megawatt reactor produces about 20 metric tons (44,000 lbs.) of high-level waste a year, and that material needs to be safely stored for 100,000 years. The 500-megawatt Transatomic reactor will produce only four kilograms (8.8 lbs.) of such waste a year, along with 250 kilograms (550 lbs.) of waste that has to be stored for a few hundred years.

In the presentation the duo projects some warming numbers for both the low cost power and the anti nuclear folks. Conventional nuclear reactors can utilize only about 3% of the potential fission energy in a given amount of uranium before it has to be removed from the reactor. The Transatomic design captures 98% of this remaining energy. A fully deployed Transatomic reactor fleet could use existing stockpiles of nuclear waste to satisfy the world’s electricity needs for 70 years, now through 2083 when about 99.2% of today’s dangerous spent fuel – would be burned away.

Even though the basic idea of a molten-salt reactor has been demonstrated the Nuclear Regulatory Commission’s (NRC) certification process is set up around light-water reactors. NRC spokesman Scott Burnell said for the next few years, the NRC will be focused on certifying the more conventional designs for SMNRs. But he also said that the commission is aware of Transatomic’s concept but that designs haven’t been submitted for review yet. The certification process for Transatomic will take at least five years once the company submits a detailed design, with additional review needed specifically for issues related to fuel and waste management.

The detailed design is years and $4 million more dollars away. Wilcox estimated that it will take eight years to build a prototype reactor – at a cost of $200 million. Low cost power customers and the antinuclear folks might want to coordinate getting the Congress to rewrite the NRC’s procedures to speed things up.

After all, China is reported to be investing $350 million over five years to develop molten-salt reactors of its own. It plans to build a two-megawatt test reactor by 2020.

It’d be a pity to miss out on a trillion dollar industrial a market and trillions more in electricity savings. Plus get rid of all that weapons ready, costly to store used fuel.

A hat tip goes to Brian Wand for spotting the latest update to Tranatomic’s progress.

Comments

2 Comments so far

Fine as a nuclear waste disposal unit, but for energy purposes it is too expensive.

Competition for Kirk Sorenson’s Liquid Fluoride Molten Salt (LFTR) designs? Competition is good. As more people become aware of molten salt reactors, the more likely for MSR development to be funded. I’d like to see commercial designs for boilers available by 2023. We’d be well served, also, by designs to produce industrial heat, mainly to make cheap hydrogen to upgrade heavy hydrocarbons.