Feb

12

A Better Thin Film Electrical Conductor

February 12, 2013 | 2 Comments

University of Illinois at Urbana-Champaign (UI) researchers have devised a method of making ferroelectric thin films with exceptional performance. The new material has improved properties, but also has entirely new properties. Most notably, the films have a built-in electric field, called an intrinsic potential. This means that it can perform some functions without needing an external current or field applied to it.

Ferroelectric materials are metal oxides with special polarization properties that are used in a number of advanced electronics applications. When electricity is applied, they can switch their polarization, or the direction of their internal electric field, which makes them useful in devices such as computer memories and actuators. Ferroelectric materials are especially useful in aerospace applications because they are less susceptible to radiation than traditional semiconductors.

Introducing “strain” in these materials can alter their properties and improve their performance. A lot of research in ferroelectric materials has focused on making strained thin films with alternating layers only a few nanometers thick of materials with slightly different crystal structures.

Lane Martin, a professor of materials science and engineering who leads the group describes the UI work with, “It turns out that if you put pressure on certain types of materials, the properties completely change. In our case we administer pressure by straining or stretching thin versions of these materials like one would stretch plastic wrap to fit on a bowl. You can induce things that don’t exist at ambient conditions; you can make phases and properties that don’t exist.”

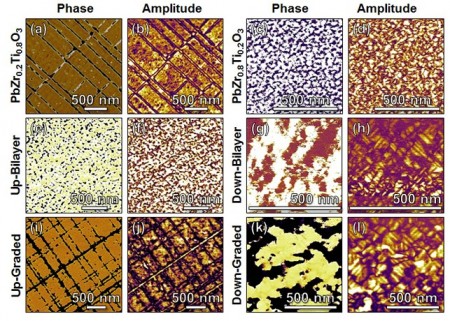

UI’s thin films are made of lead zirconate titanate (commonly called PZT). The relative amounts of zirconium (Zr) and titanium (Ti) in the films determine the shape of the crystals. Traditionally, films of PZT have been made up of a single composition, grown directly on a substrate with a slightly different crystal structure to cause strain in the PZT. However, too much strain causes the PZT to revert to its original crystal structure. This limits researchers’ ability to change the properties of these materials for better device performance.

The UI group overcame this limitation by gradually shifting the concentrations of Zr and Ti as they grew the thin films, incrementally changing the crystal structure. From layer to layer, the structures are very similar, yet the composition of the PZT at the top and bottom of the film is very different, transitioning from a PZT composition with an 80% Zr to a 80% Ti. This gradual change, instead of the usual layered approach, results in little localized strain but large overall strain.

Martin explains the results, “We have taken a material with similar mechanical properties to a dinner plate, the same kind of hardness, and effectively figured out a way to stretch that plate without breaking it. With our method, we’ve been able to extend our ability to strain these materials. We go to the nanoscale so we can pull on these films and dramatically change the shape, and that affects the properties.”

Building up a circuit of the new highly strained PZT composite material not only has improved properties, but also entirely new properties. Most notably, the films have a built-in electric field, called an intrinsic potential. This means that it can perform some functions without needing an external current or field applied to it. In addition, it means that the material has a preferred polarity, which opens the door for new applications.

Graduate student and co-author of the paper Karthik Jambunathan explores the manufacturing advantages, “This sort of built-in field is very useful, otherwise you have to engineer similar effects using features not native to the materials to have the same thing happen, but it is much more difficult and less easily controlled. Here, it’s grown into the material to begin with.”

As a practical example, ferroelectric materials have been widely used in memory applications that rely on spontaneous polarization. But to read a bit of data in computer memories made with a traditional ferroelectric material, its polarity is physically switched. That means every time the bit is read, it has to be re-written and compared to a reference bit. But if the material had a built-in electric potential, engineers could make bits that would not need to have their polarity switched to be read, so computer components made with the new material could be smaller, faster and longer lasting.

Next up the UI team plans to explore potential applications further, as well as apply their gradient film technique to other types of ferroelectric materials in search of even more novel and unexpected properties.

A confident Professor Martin said, “This is just the beginning. There are an infinite number of varieties of gradients that you could think about. This is a smooth gradient, but we could skew it, or change what the end members are. Each one of these is going to give its’ own set of structures and potential properties that we haven’t even begun to scratch the surface of. I think the capacity for finding new types of materials and properties is really open here.”

These are impressive results. The possibilities range across the whole field of electrical materials, circuits and products. This is innovative thinking at its best.

Comments

2 Comments so far

What’s up friends, how is all, and what you wish for to say concerning this article, in my view its actually remarkable in favor of me.

you are in reality a good webmaster. The site loading speed is incredible.

It seems that you’re doing any unique trick. Also, The contents are masterwork.

you have performed a excellent job in this subject!