Sep

28

Cyanobacteria Closes in On Algae for Fuel Production

September 28, 2012 | 1 Comment

Arizona State University scientists have developed a new method that relies on heat to improve the yield and lower the costs of high-energy biofuels production from cyanobacteria. ASU has also been at the forefront of algae research for renewable energy production.

ASU has run a dual role since 2007 with support from federal, state and industry funding with both algae and cyanobacteria research.

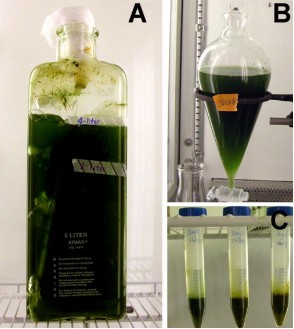

ASU has run several projects that utilize the photosynthetic cyanobacteria microbes as a potential new source of renewable, carbon-neutral fuels. Efforts have focused on developing cyanobacteria as a feedstock for biodiesel production, as well as benchtop and large-scale photobioreactors to optimize growth and production.

Cyanobacteria are like plants, dependent upon renewable ingredients including sunlight, carbon dioxide and water that, through genetic engineering, can be altered to favor biodiesel production. Cyanobacteria offer attractive advantages over the use of plants like corn or switchgrass, producing many times the energy yield with energy input from the sun and without the necessity of taking arable cropland out of production.

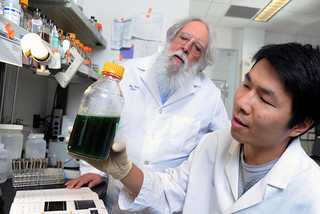

Roy Curtiss, director of the Biodesign Institute’s Centers for Infectious Diseases and Vaccinology and Microbial Genetic Engineering as well as professor in the School of Life Sciences and colleague Xinyao Liu have spent the last few years modifying the cyanobacteria. Their goal is to bypass costly processing steps (such as cell disruption, filtration) for optimal cyanobacterial biofuel production.

Curtiss explains the background, “We wanted to develop strains of cyanobacteria that basically can process themselves. A couple of years ago, we developed a Green Recovery process that is triggered by removing carbon dioxide to control the synthesis of enzymes, called lipases, that degrade the cell membranes and release the microbes’ precious cargo of free fatty acids that can be converted to biofuels.”

However, when growth of cyanobacteria is scaled up to meet industrial needs they become dense, and the self-shading that occurs in concentrated cultures doesn’t let in enough light to produce enough of the lipases to efficiently drive the process. Thus the original Green Recovery was light dependent and maximally efficient at sub-optimal culture densities.

“We keep trying to reach ever deeper into our genetic bag of tricks and optimize bacterial metabolic engineering to develop an economically viable, truly green route for biofuel production,” said Curtiss.

The team looked again at nature to improve their Green Recovery method. The new process uses enzymes found in nature called thermostable lipases synthesized by thermophilic organisms that grow at high temperatures such as in hot springs. These thermostable lipases break down fats and membrane lipids into the fatty acid biodiesel precursors, but only at high temperatures. The study results have been published in the online version of the Journal of Biotechnology.

The team’s new process, called thermorecovery, uses a heat-triggered, self-destruct system. By taking a culture and shifting to a higher temperature, the lipases are called into action. This process occurs with concentrated cultures in the dark under conditions that would be very favorable for an industrial process.

The team tested a total of 7 different lipases from microbes that thrive in hot springs under very high temperatures, a scorching 60-70º C (158º F). The research team swapped each lipase gene into a cyanobacteria strain that grows normally at 30º C (86º F) and tested the new strains.

They found the Fnl lipase from Feridobacterium nodosum, an extremophile found in the hot springs of New Zealand, released the most fatty acids. The highest yield occurred when the carbon dioxide was removed from the cells for one day (to turn on the genes making the lipases), and then treated at 46º C (114º F) for two days (for maximum lipase activity).

Are you sitting down? The yield was 15% higher than the Green Recovery method, and because there were less reagents used, time (one day for thermorecovery vs. one week for Green Recovery) and space for the recovery. Thermorecovery resulted in an estimated 80% cost savings.

On top of all that, in a continuous semi-batch production experiment, the team showed that daily harvested culture releases could release a high level of fatty acid and the productivity could last for at least 20 days. Plus, the water critical to growing the cultures could be recycled to maintain the growth of the original culture.

Curtiss winds up the news with academic understatement, “Our latest results are encouraging and we are confident of making further improvements to achieve enhanced productivity in strains currently under construction and development. In addition, optimizing growth conditions associated with scale-up will also improve productivity.

Curtiss has been at this a while. He’s a microbiologist who uses genetic engineering of bacteria to develop new vaccines. Cyanobacteria like algae is a single cell organism, but is a very different critter from a metabolism point of view. The potential hasn’t garnered the attention that algae has, yet cyanobacteria may prove to be much superior.

The yield improvement is a pleasant surprise, but that cost cutting is astonishing, especially when one recalls the cyanobacteria will be releasing ready to process fuel and chemical precursors.

Comments

1 Comment so far

Good luck to Professor Dumbledore and his whole team.