Aug

14

A Breakthrough in Electricity From Wastewater

August 14, 2012 | 2 Comments

Wastewater, more commonly thought of as sewage or gray water is estimated to use 3% of the electrical energy consumed in the United States and other developed countries.

Engineers at Oregon State University have made a breakthrough in the performance of microbial fuel cells that can produce electricity directly from wastewater. There have been other ideas pursued in the past, but the new technology can now produce 10 to 50 more times the electricity, by volume, more than most other approaches using microbial fuel cells, and 100 times more electricity than some.

The new microbial fuel cell technology cleans sewage by a very different approach than today’s aerobic bacteria systems. Microbial fuel cell bacteria oxidize the organic matter and, in the process, produce electrons that run from the anode to the cathode within the fuel cell, creating an electrical current. Almost any type of organic waste material can be used to produce electricity – not only wastewater, but also grass straw, animal waste, and byproducts from such operations as the wine, beer or dairy industries.

Hong Liu, an associate professor in the OSU Department of Biological and Ecological Engineering looks ahead saying, “If this technology works on a commercial scale the way we believe it will, the treatment of wastewater could be a huge energy producer, not a huge energy cost. This could have an impact around the world, save a great deal of money, provide better water treatment and promote energy sustainability.”

The OSU team says the development could eventually change the way that wastewater is treated all over the world, replacing the widely used aerobic “activated sludge” process that has been in use for almost a century. The new approach would produce significant amounts of electricity while effectively cleaning the wastewater.

The biodegradable characteristics of wastewater, if tapped to its full potential, could theoretically provide many times the energy that is now being used for processing, with no additional greenhouse gas emissions. How many times that 3% could be multiplied begs a better answer.

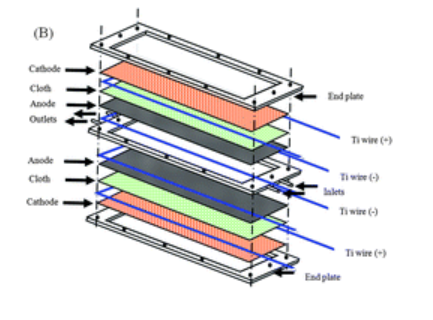

OSU researchers reported several years ago on the promise of wastewater microbial fuel cell technology, but at that time the systems explored produced far less electrical power. With new concepts like reduced anode-cathode spacing, evolved microbes and new separator materials, the technology can now produce more than two kilowatts per cubic meter of liquid reactor volume. This amount of power density far exceeds anything else done with microbial fuel cells.

On the efficiency front the OSU system also works better than an alternative approach to creating electricity from wastewater, based on anaerobic digestion that produces methane. The OSU system treats the wastewater more effectively, and doesn’t have any of the environmental drawbacks of that technology, such as production of unwanted hydrogen sulfide or possible release of methane, a potent greenhouse gas.

The progress level has now been proven at a substantial scale in the laboratory. Lui reports the next step would be a pilot study and funding is now being sought to run such a test. A good candidate, she said, might initially be a food processing plant, which is a contained system that produces a steady supply of certain types of wastewater that would provide significant amounts of electricity.

The OSU team’s press release proposes continued research should also find even more optimal use of necessary microbes, reduced material costs and improved function of the technology at commercial scale.

The team has also looked at the financial matters. While wholly preliminary, once advances are made to reduce high initial costs, the researchers estimate that the capital construction costs of this new technology should be comparable to that of the activated sludge systems now in widespread use today – and even less expensive when future sales of excess electricity are factored in.

The approach may also have special value in developing nations, where access to electricity is limited and sewage treatment if used at all can be at difficult or impossible remote sites.

The ability of microbes to produce electricity has been known for decades. Its great to see technological advances made the production of electricity high enough to be of commercial use.

Comments

2 Comments so far

What do WWTP do? They take a dilute stream of polluted water (typical 300 ppm BOD – bio oxy demand) and transform it to less than 10 soluble BOD. It goes from dilute to extremely dilute. It’s a helluva trick, because we do hate it when the “goodie” is in dilute form. Chem engineers know what I’m saying.

Now, we also have to take the ammonia (comes from breakdown of proteinaceous materia, eh?) Ammonia is toxic in surface water. So in domestic service we go from 50 ppm NH3-N to 2 – 5 ppm NH3-N. Microbes will do this for you, but only in a second stage after you have sucked up most of the BOD.

Oh, yes, to keep waterways from looking like algae farms, we also must encourage our microbes to sequester phosphates. Not easy, but do-able.

Maybe the microbial fuel cell can utilize a side-stream of the waste. Certainly it’s a tantalizing dream to realize a benefit from the waste. But there’s a helluva lot more to it than just grabbing the carbonaceous material, and even if you did, you’d never clean it to the regulatory requirement without some good ol’ micro-organisms.

And other tech battle. You could use anaerobic digester gas (mostly methane), for instance, in a ceramic fuel cell and directly generate volts. So where’s the practical and economic comparison of methods?

JP Straley

jp,

It just may end up being more economical than building anaerobic digesters and there operational headaches. You also have to concentrate the influent sludges with primary treatment or Imhoff Cone Tank designs – not so with this process.

Also, 300 ppm of BOD is just about the national average of domestic raw sewage entering our present treatment plants and 10 ppm is what usually is still present in the final effluents without further expensive treatments either physical, chemical, biological or some combination of all.

These Microbiological Fuel Cells hold great promise in MHO…