Apr

25

A New Idea On Getting the Energy From Oil Shale

April 25, 2011 | 2 Comments

A team at Stanford University is proposing using solid oxide fuel cells as the basis for a method for electricity production from oil shale with in situ carbon capture called “electricity production with in situ carbon capture” (EPICC) as a means to provide transportation services from oil shale with greatly reduced CO2 emissions.

If such an idea would work at scale billions of barrels of oil shale — now regarded as off-limits because of the huge amounts of carbon dioxide released in its production would be available as an energy source.

The authors of a paper in the ACS journal Energy & Fuels Adam Brandt and Hiren Mulchandani, explain that almost 3 trillion barrels of oil are trapped in the world’s deposits of oil shale, a dark-colored rock laden with petroleum-like material. The United States has by far the world’s largest deposits in the famed Green River Formation, which covers parts of Colorado, Utah, and Wyoming. Estimates put that total domestic oil resource at 1.2 trillion to 1.8 trillion barrels.

The problem today is the processes now available generate huge CO2 emissions that won’t sell politically and consume so much heat that commercial viability commands a reliable very high price of crude oil – another not politically viable premise.

The Stanford scientists’ idea goes to a process that would be self-fueling, using the process’s own fuel release to keep the process going.

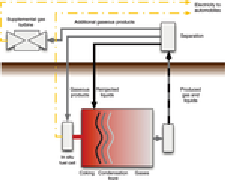

EPICC System Diagram. This is as large as it gets - no fair use allowed. Click image for more information.

In the EPICC process waste heat from a solid oxide fuel cell (SOFC) that’s placed in the formation is transferred via conduction into the oil shale. The heat causes kerogen and bitumen to decompose into liquid and gaseous hydrocarbons in a simple process called retorting.

As the heated and vaporized liquid hydrocarbons move toward producer wells and contact cooler shale, some condensation occurs. As further heating continues the liquid hydrocarbons crack into low-molecular weight gases like methane, hydrogen, carbon monoxide and carbon dioxide (CH4, H2, CO, CO2) and char or a kind of shale rock infused with charcoal.

The process would convert much of the organic carbon lacking the necessary hydrogen in oil shale into the char, which is simply left in the formation. The key is to get a temperature and heat front moving such that all the hydrogen and the proper amount of carbon move out together.

Production of hydrocarbon gases are then fed back into the fuel cell to generate electricity and to provide more waste heat for the retorting to continue. The excess gas can be sent to a combined cycle gas turbine to produce additional electricity.

In this plan the solid oxide fuel cell primarily generates electricity, its secondary heat releases more fuel that can be used for more power generation.

What makes the idea so interesting goes beyond the CO2 emission matter. The first SOFC output is electricity for sale. The second is the waste heat runs the fuel recovery right into the oil shale. Little is wasted, little in the way of emissions. Then the excess product not used to drive the fuel cell is for sale.

The key is the reordering of output. The chemical energy in the oil shale is converted first to electricity in the formation instead of a spending a great effort to recover chemicals and burn them outside the fuel source.

Brandt and Mulchandani try to make clear in the paper that using the EPICC process for straight to natural gas production would consume significant amounts of primary energy and result in a lower value product than the oil that was destroyed to produce gas. EPICC produces gas from the electricity production waste heat. For this idea to work economically – be happy to get the electricity first.

The paper also makes clear that high carbon taxes would impact the idea’s viability quite favorably. Leaving the char behind instead of digging the oil shale whole and processing that way leaves a serious carbon tax out of the forecast of costs.

Other points are the practicality of running a solid oxide fuel cell deep underground, the issues of controlling the gas and fluid pressures, unexpected heat and product migrations, and the matter that the process of retorting takes quite a lot of time.

But if the market goes the way of looking for electricity, accepting a mostly hydrogen stripping out of the largest oil reserve on earth, and the willingness to leave an unknown stranding of energy – the Stanford idea might look pretty good.

The value of the Brandt and Mulchandani work is the innovative way of looking at the points of resource use and the revenue streams from the process. Here the pair has shown ingenuity, innovation and exemplary computer modeling work. What becomes of the Green River Formation isn’t a sure thing or that it will ever be exploited. But some impressive minds are at work and the newest idea might be something market worthy. Lets hope the research continues so the EPICC can get firmed up so its more than just an idea in a computer model.

Comments

2 Comments so far

An interesting seed for an idea. Any plan for kerogen shale will need to be very sparing of water, and cause virtually no change to the natural landscape.

In order to make it a full-featured plan, one would need to add some features:

make the unit a rock-mobile robot by adding a self-powered drilling module and traction capacity

design the robotic unit to lay pipeline and power cable behind it as it passes through the kerogen shale formation along a carefully planned route

for extra heating capacity, pack the robot with well-shielded used nuclear fuel

alternatively, for more efficient operation, ditch the SOFC and use a robotic small modular nuclear reactor (SMR) instead, for CHP (combined heat and power) and have the robot lay the pipeline for the hydrocarbon product and power cable for excess electric power as it goes AND provide the pumping power to pump product to the surface.

Even better, locate SMR(s) at the surface for in situ release of hydrocarbon from the rock by methods which use minimal or no water, such as Raytheon’s microwave technology, which uses super-critical CO2 as extraction fluid.

The price of oil will plummet as soon as the world discovers Dr. Rossi’s cold fusion. See why at http://nickelpower.org/2011/04/13/what-will-happen-to-the-price-of-oil/ If the price of oil plummets, will oil from oil shale survive? I doubt it.