Dec

14

A Metal Air Battery Dream Gets Traction

December 14, 2010 | 8 Comments

Scottsdale Arizona-based startup Fluidic Energy is looking far into the future. With a focus on a metal-air ionic liquid battery, Fluidic Energy has just received a $5.13 million research grant from the U.S. Department of Energy to expand its plan. This follows a $3 million grant in July through the Advanced Research Projects Agency for Energy, (see slide 23) which was funded by the American Recovery and Reinvestment Act. The company also has the backing of inverter manufacturer Satcon and Chevron Energy Solutions.

Today’s common metal air models use water-based electrolytes that are prone to evaporation, and in turn, premature battery failure. Water-based batteries also start to decompose when the cell exceeds 1.23 volts, making existing metal-air models virtually useless for long term electric vehicle use. More challenging yet, these kinds of cells are usually not recharged due to dendrite buildup during the recharging cycle. This results in the cell shorting out and not holding a charge when the dendrites connect the anode with the cathode.

Fluidic Energy is researching and developing a simple fix— exchanging water-based electrolytes for liquid salts also known as ionic liquids that can supercharge metal-air batteries such that they have 11 times the energy density of lithium-ion batteries and cost a third of the price. A car running on metal-air could potentially travel 400-500 miles on a single charge, making an extensive electric vehicle charging infrastructure a luxury rather than a necessity.

But metal-air ionic liquid batteries aren’t quite ready for commercial scale. Ionic liquids are expensive today because they are often made in small quantities. But, that could easily change if metal-air becomes the battery of choice for electric vehicles. Meanwhile Fluidic Energy faces a cost barrier.

Another problem is lithium-ion battery facilities are ramping up production around the world, so it will be problematic that an entirely new type of electric vehicle battery will find its way into vehicle production – unless that 11 times capacity and 66% cheaper disruption becomes real. Then all bets on lithium-ion would be quickly called off. Tripling the capacity per unit cost and an order of magnitude improvement can’t be overlooked; the accountants will win on this, easily.

It’s no wonder that major researchers such as IBM who is heavily funding a sort of consortium working to a metal air solution.

Fluidic Energy’s idea stems from Cody Friesen, a professor of materials science at Arizona State and founder of Fluidic Energy. Friesen says the use of ionic liquids overcomes many of the problems that have held back metal-air batteries in the past. “I’m not claiming we have it yet, but if we do succeed, it really does change the way we think about storage.”

The U.S. Air Force Academy began about 25 years ago with experiments with ionic liquids – salts that are a liquid at room temperature, and which often can remain a liquid in sub-zero temperatures or above the boiling point of water. John Wilkes, the leading ionic liquids expert who heads the academy’s chemistry department said, “They’re wonder fluids. They’re remarkable. If you look at these liquids in a bottle, they look like water, except they’re viscous. They’re not volatile, they don’t evaporate, they’re physically stable and they conduct electricity fairly well.” Understandably an excited guy now that his work is finding a developing home.

Friesen takes the thoughts further saying a metal-air battery using an ionic liquid as its electrolyte not only functions significantly longer – because drying out is no longer a problem, but it also gets a big boost in energy density. “These liquids have electrochemical stability windows of up to five volts, so it allows you to go to much more energy-dense metals than zinc.” There’s a future clue and question, what is the Fluidic Energy metal choices beyond zinc?

Hold on, Friesen’s research team will target energy densities of at least 900 watt-hours per kilogram and up to 1,600 watt-hours per kilogram in the DOE-funded project.

The experts across the articles available on the Internet all seem to play on the commercial costs. Friesen is downplaying the matter pointing out that the liquids become quite economical when developed in-house in large volumes. He’s careful, however, not to say too much about the ionic liquids his team has developed, revealing only that there are “several contenders that seem to work well.”

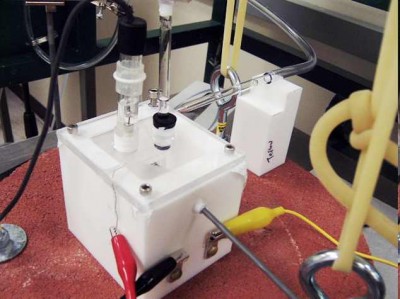

Due to proprietary interests Friesen is cautious when talking about the other key component of Fluidic Energy’s research: a metal electrode structure that overcomes the problem of those dendrites forming and cause a metal-air battery to short-circuit. Dendrite formation happens in rechargeable batteries when the chemical reactions are reversed, limiting the number of charging cycles. Fluidic Energy has developed an electrode scaffold with multi-modal porosity, meaning it has a range of pore sizes down to as small as 10 nanometers. The scaffold surrounds the metal, reported to be zinc for now, and can prevent dendrites that form during charging.

As we saw just yesterday, the coating potential is wide and deep. Fluidic Energy might not have the only pathway to success as other innovations pop up.

Full of confidence and likely justified, Friesen’s ability to eliminate evaporation, and dendrites, plus boost voltage leads to an intriguing comment, “We’re working now on taking it to the next level. It’s about taking everything we’ve done over the last four years and leveraging that work into a battery that looks and feels just like a lithium battery, but has energy densities far beyond that.”

If the reports are right, the cost will be a bit more than equivalent lead acid at weights and capacities 10 to 12 times the range of the 40 mile electric vehicle of today.

Wilkes’ comment puts a little zip in the confidence saying “But some people are making ionic liquids now out of things that are already known and produced in high quantities, like detergents.” IBM and the others need to pick up the pace, the coming bar looks very high. The lithium miner’s growth could also get a major extension into the future.

Then this news slipped out, Fluidic Energy has committed to bringing a manufacturing facility to Maricopa County along with several hundred jobs according to Barry Broome, president and CEO of the Greater Phoenix Economic Council.

Dare to say this technology is getting under way? In the home state of the losing presidential contender? Humm . . .

Comments

8 Comments so far

The 400 mile per charge car is what it’s going to take to make the electric car a viable option.

Not to mention, what this would do for the electric motorcycle which will become a mainstay of the 3rd world.

How does this invention compare to gasoline or diesel for energy density?

JP Straley

jp staley asked “How does this invention compare to gasoline or diesel for energy density?”

Great question. A kilogram of gasoline has 12.8 kWH of energy. A gas engine is 25% efficient so the useful energy content is 3.2 kWH/kg. The target for the battery is 1.6 kWH/kg.

The Chevy Volt uses 0.32 kWH/mile according to a Motor Trend magazine test. 1kg of battery gives 5 miles range. A 60kg battery provides 300 miles range.

A 30 mpg gas car would need 27kg of fuel to travel 300 miles.

This puts the battery weight at two times the weight of gasoline for the same range. In a 1500kg car the battery would be only 4% of vehicle weight. This battery would definitely be practical.

I heard that FluidicEnergy is stepping up to mass produce the battery soon. That’s awesome.

But I do not know where the plant is.

Another interesting line of research regarding energy generation and storage. Somewhere in all this is the brave new world.

What about turning the ionic liquid into something of Gel like texture with addition of elements to create a strong ionic bond. Should help increase the usage of such batteries in harsh environments.

Dare to say this technology is getting under way?

This technology will pick up very soon and will be a very successuful initiative