Nov

16

A Baking Soda Solution for Algae Growth

November 16, 2010 | 3 Comments

A Montana State University team of interdisciplinary researchers has discovered that baking soda, the common name for sodium bicarbonate, can dramatically increase algae’s production of the key oil precursors for biodiesel and biojet fuels. That’s right, the household chemical that causes cookies to rise in the oven, calms upset stomachs and removes odors from refrigerators is the elusive chemical trigger that scientists have sought since the early 1990s to drive extreme algae oil production.

The observation is not an error – when added at a particular time in the growing cycle, baking soda more than doubled the amount of oil produced in half the time in three different types of algae.

Rob Gardner, an MSU graduate student in chemical and biological engineering said, “It took a lot of work. I was pretty thrilled when it all came together. I’m still kind of in shock about it.” Rob, you’re not alone. Twice the product in half the time is stunning.

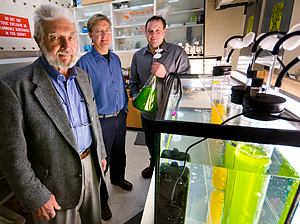

MSU is now offering the algal biofuel technology for licensing. With Gardner the interdisciplinary team members are longtime algae experts — Keith Cooksey, research professor emeritus in microbiology, and Brent Peyton, professor in chemical and biological engineering and associate director of MSU’s Thermal Biology Institute. Representing the College of Engineering and College of Letters and Science, all three belong to MSU’s Algal Biofuels Group, “one of the best cooperative research groups on campus,” according to Cooksey.

Here’s a bit of surprise, way up in Montana, the Algal Biofuels Group is part of MSU’s Energy Research Institute, an umbrella for roughly 35 faculty working in a variety of disciplines. About $15 million in sponsored energy research is conducted at MSU annually. Way up in Montana, no less. Granting agencies take note.

Lee Spangler, the Energy Research Institute director said, “We are looking at everything from biofuels, to fuel cells, to wind, to carbon sequestration. This work by the algal group is an exciting example of how we take university research and make it available to the private sector through licensing.”

The MSU algal group also belongs to the Algal Biomass Organization, the world’s largest group devoted to algal biofuel. Peyton presented MSU’s discovery to that group in late September. It was one of four presentations on biofuel from MSU. It sure took long enough to get the press release out.

On the technical side Cooksey taught Gardner how to grow the algae they used in their experiments. Gardner grew the algae in beakers and tubes in three labs across campus. He then conducted experiments and shared his progress with Cooksey and Peyton. Gardner worked for about 1 1/2 years before the trio confirmed that baking soda was the chemical trigger they’d been seeking. They made their initial discovery in two kinds of brown algae and one type of green. Gardner notes, “It was a lot of trial and error and failure. We finally came across the right combination.”

Cooksey explains the baking soda may work because it gives algae extra carbon dioxide necessary for its metabolism at a key point in its life cycle. If the baking soda is added too early or too late, the algae don’t respond. But when added at just the right time in the growth cycle, algae produce two to three times the oil in half the time of conventional growth models. The oil, or lipid, is composed of triacylglycerides, the key precursors to biodiesel and biojet fuel.

In processing a doubling to tripling production in half the time is a massive improvement. Cookley adds the time issue also helps with algal-producing ponds that are prone to contamination. If growers can produce oil faster, they can reduce the opportunity for contamination to ruin the product. That makes a more, quicker, at less risk process discovery. Congratulations are in order.

Peyton said the three types of algae used in the MSU study were not closely related, so the MSU discovery should have broad application adding, “We are working on demonstrating this in other varieties.”

Such a massive production process improvement should offer the post growth processes a lower cost raw material. There remain many tasks in getting oil separation and oil refining to fuel that keeps algae production too expensive for competitive market growth. But the MSU group has certainly launched a blast of high value innovation that will impact everyone downstream in the algae to fuel research community.

Algae are coming, inching along. MSU just gave us about a yard. Good work!

It seems that sodium bicarbonate producers are stocks to watch now too.

Comments

3 Comments so far

The oceans contain 93% of the world’s carbon dioxide, and 91% of ocean CO2 is as bicarbonate HCO3- . Besides being a very effective buffer, the HCO3 apparently serves as an excellent food for phytoplankton such as algae.

Just like land plants, sea algae love CO2, whether as gas or as the buffer ion.

Keep posting stuff like this i really like it

Great site. A lot of useful information here. I’m sending it to some friends!