Nov

6

Progress on Zinc-Air Batteries

November 6, 2009 | 3 Comments

ReVolt, a Swiss company, plans to sell small “button cell” batteries for hearing aids starting next year. ReVolt has developed rechargeable zinc-air batteries that can store three times the energy of lithium ion batteries, by volume, while costing only half as much. The company plans to incorporate its technology into ever-larger batteries, introducing cell-phone and electric bicycle batteries in the next few years and is starting to develop large-format batteries for electric vehicles.

The source of the technology was developed at SINTEF, a research institute in Trondheim, Norway. ReVolt was founded to bring it to market and has 24 million euros in investment capital to start.

Conventional batteries like alkaline and lithium are sealed with all the reactants needed to generate electricity self-contained within. Zinc-air, and the other ‘air” batteries rely on oxygen from the atmosphere for reacting to generate the current. The battery chemistry is also comparatively safe because it doesn’t use volatile materials, thus zinc-air batteries are not prone to self-ignition such as some lithium-ion battery technology. In prior decades back to the 1980s zinc air was considered one of the most promising battery technologies because of their high theoretical energy-storage capacity.

The nonrechargeable zinc-air batteries have been on the market for hearing aids in particular for a long time. They’re available at most pharmacy and personal care stores at low prices. But making them rechargeable has been a challenge.

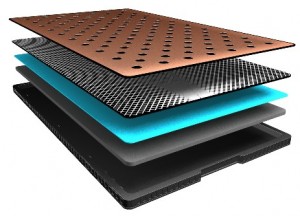

Inside an air battery, a porous ‘air’ electrode draws in oxygen and, with the help of catalysts at the interface between the air and a water-based electrolyte, reduces it to form hydroxyl ions. These travel through an electrolyte to the zinc electrode, where the zinc is oxidized the reaction that releases electrons to generate a current. To recharge the process is reversed, the zinc oxide is converted back to zinc and oxygen is released back from the air electrode. With repeated charge and discharge cycles the air electrode will be deactivated, slowing, then stopping the oxygen reactions.

One way to deactivate is the liquid electrolyte being gradually pulled too far into the zinc’s pores, another is if it dries out or if zinc builds up unevenly so forming zinc crystal structures that form a short circuit between the electrodes.

ReVolt claims it has developed methods that control the shape of the zinc electrode malformations using certain gelling and binding agents) and for managing the humidity within the cell. ReVolt also tested a new air electrode that has a combination of carefully dispersed catalysts for improving the reduction of oxygen from the air during discharge and that boosts the production of oxygen during charging. The prototypes have operated well beyond one hundred discharge and recharge cycles.

The company’s first products are expected to be useful for a about two hundred cycles. James McDougall, the company’s CEO,hopes to increase this to between 300 and 500 cycles, a point that will make them useful for perhaps mobile phones and electric bicycles. They’re going to have to be cheap, even at 350 cycles that’s only a year of cell phone recharges.

To answer the huge demands of vehicles ReVolt is developing a unique zinc-air battery structure that’s reminiscent of a fuel cell. Its first vehicle battery designs use two flat electrodes, which are similarly sized. One electrode will be a liquid a sort of zinc slurry. The air electrodes will be in the form of tubes. To generate the electricity, the zinc slurry stored in one compartment in the battery, is pumped through the tubes where it’s oxidized, forming zinc oxide and releasing the electrons. The zinc oxide then accumulates in another compartment in the battery. During recharging, the zinc oxide flows back through the air electrode tubes, where it releases the oxygen, reforming back into zinc again.

The key in that design is the amount of zinc slurry can be much greater than the amount of material used making in the air electrode tubes thus substantially increasing the energy density. Such a system can be thought of such that the zinc slurry would essentially act as a fuel as its pumped through the air electrode like the hydrogen in a fuel cell or the gasoline in a combustion engine. That’s plausible; the zinc slurry gets filled with energy from electric charged and discharges that energy back in the reversed reaction. No combustion, but still a “fuel like” operation.

McDougall says the ReVolt battery research could develop longer life, from 2,000 to perhaps as much as 10,000 cycles. Due to the very low risk chemistry, if one part fails, such as the air electrode tubes they could be replaced, perhaps in a module, eliminating the need to buy a whole new battery.

Zinc-air is still a chemical battery though. For large current draws and quick regenerative braking charges as would be seen in vehicles they’ll need capacitors for fast action.

ReVolt isn’t alone in the zinc-air field. Issues like operating temperatures, ambient temperature effects, weight, efficiency factors, new costs and the lifespan issues challenge all the up and coming researchers and companies. But pound for pound, zinc air has a huge and tantalizing advantage that must worry the lithium investors.

Better count ReVolt in the leader’s group. After all, they’re sharp enough to set up in Switzerland, the low tax, business friendly, bastion of sanity in the European Union.

Comments

3 Comments so far

Anyone any idea of the energy efficiency of the process zinc-zinc oxide-zinc?

We are obviously in a very different game if it is, say, 25% compared to 80%.

This is an excellent article. Thanks for the information.

This is such a great resource that you are providing and you give it away for free. I enjoy seeing websites that understand the value of providing a prime resource for free. I truly loved reading your post. Thanks!