Jun

17

A New -And Its Real- Nuclear Reactor

June 17, 2009 | 3 Comments

Babcock & Wilcox announced last week that it’s new subsidiary B&W Modular Nuclear Energy, LLC will be offering a new design that’s passively safe, scalable and modular using the old light water reactor method. That might not sound like a big deal, but in the face of the regulatory thresholds to cross, it’s a very smart strategy.

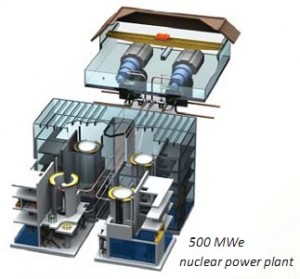

The new modules are sized to the 125 to 750 MWe outputs. Those sizes get to the good sized plant at the large rating and at the small end offers upgrades to current facilities and module reactors can be added as needs increase. The shift out from reactors that shouldn’t need the giant confinement domes may well be coming, so dropping construction costs.

The reactors are five-year fuel cycle devices or they run continuously for five years without a refueling. Emissions are nil outside of the needs for the building and construction of rectors and the sites. This has to make sensible environment types happy and relieve consumers that sure supply at affordable prices might still be the future.

The B&W site lists these features:

- Integral nuclear system design.

- Passive safety systems.

- Underground containment.

- Five-year operating cycle between refueling.

- Scalable, modular design is flexible for local needs.

- Multi-unit (1 to 10+) plant.

- Used fuel stored in spent fuel pool for life of the reactor (60 years).

- North American shop-manufactured.

These features when viewed in a combined set offer a dramatic change in nuclear power. Today a utility would ask the government for permissions to build something that has already been through the bureaucratic grinder. That something would be an approved design. The application then would go through whatever hoops have been set up by law and the regulations. The process takes years, million of dollars and may or may not be approved. It’s a big risk for the utility and its customers. Remember, utilities can go broke, too.

Having smaller reactors that could be ganged together for larger output could well cut those costs, or perhaps reduce the repeated application process. The passive safety design also sets up a simpler and easier to run training and safety program. Mounted below ground minimizes a wealth of issues that above surface installations would need. Perhaps most importantly is the reactor can be manufactured, permitting the economies of volume and standardization to work, in a factory with the opportunity to have more intense quality control and mass-produced parts. One would really like to see the dollar numbers comparing a manufactured unit vs. an on site, single design, custom built with all the safety and containment paraphernalia a current reactor needs.

B&W believes this optimized ALWR Generation III++ nuclear technology can be certified, manufactured and operated within today’s existing regulatory, industrial supply chain and utility operational infrastructure. If they pull that off, the unit can be delivered by rail. Now that’s a major change, indeed.

Another notable issue is the construction period is; now grab your seat belt, only three years. That aspect also is a cost reducing issue that leads to others when considering the modular design. One can be built and running while others are added over time.

The environment is also going to benefit. The estimate is 57 million tons of CO2 will not be emitted over the life of the new reactors. That really means less coal and natural gas gets burned allowing the supply to feed other markets. The local impacts are minimal as well. These reactors are not very big. Underground installation keeps them out of the way from such as tornadoes and terrorist’s planes. The steam condenser is air cooled, which should be a source for secondary energy recovery.

That’s all for the good. The political side isn’t so bright. Obama has killed the Yucca Mountain used fuel repository. The Republicans showed up for the company’s press conference totaling four, three Senators and a Representative. One Democrat showed up. Not good. But we’re here, watching. Fusion and thorium are years off, so this move by Babcock & Wilcox is timely.

The issue of interest though, reactor fuel efficiency isn’t covered, a disappointment. One would expect good numbers here, as it’s a later design.

Yet it’s timely because this is a certain remedy for using so much coal, the excuse behind the cap and trade scheme. It’s a case of using innovation and technology to improve the electrical power supply that may well lead to more and cheaper. It’s just the medicine for an ailing economy and well, energy for economic growth and progress.

That puts the Hyperion small reactor and now the Babcock and Wilcox “mPower” reactor front and center for uranium fueled reactors. Both are modular, transportable and much less expensive than the old technology and likely the huge later generation reactors for new installations. Things are looking very good form a technology standpoint. Now if the economy and the politicians could catch up, an economy with high efficiency electrical power could come to the future soon.

Other takes: The Wall Street Journal, the estimable Geoffrey Styles on Thursday June 11, 2009 and Rod Adam’s Atomic Insights Blog.

Comments

3 Comments so far

April Fool! This is really a schematic for the handle of a Jedi LightSaber.

(Ha ha, made you look!)

Anyway, I really would like to know more about the passive safety features of the reactor.

[…] A New -And Its Real- Nuclear Reactor […]

Thanks for some quality points there. I am kind of new to online , so I printed this off to put in my file, any better way to go about keeping track of it then printing?