Feb

12

Poking Holes in Corn for Ethanol

February 12, 2009 | 8 Comments

Electroporation or electropermeablization is electrical pulses quickly applied to cell’s walls or the cell plasma membrane that poke holes or permeate cells such that materials can be sent into a cell or extracted. It’s being used now in the medical field to introduce medicines into cells. The process is now about to come to market to create pores corn cells to allow the starches out and allow enzymes in to speed and reduce the costs to produce ethanol. We’ll be back to that, but first:

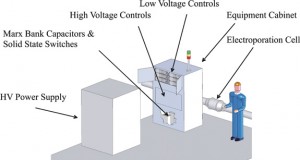

OptiSwitch of San Diego California became interested in ethanol about two years ago. With experience from critical military applications with reliable solid state switches from their own investment and a $10 million contract from the Department of Defense, OptiSwitch is producing high-power, short-duration electrical systems, or “pulsed power,” which use high voltages—10,000 to more than 100,000 volts—and high currents—10,000 to more than 100,000 amperes—for durations of hundreds of microseconds or less. That experience leads to a process of small amounts of electricity used to speed up the starch extraction and enzyme infiltration.

Optiswitch is looking into the process as a pretreatment for cellulosic feedstocks that may eliminate the need for steam explosion or acid hydrolysis, both issues that reduce the feedstock yields for fermentation.

The process is also in research for algae based biodiesel production. The process promises to solve in a large way the dewatering of algae and the extraction of the oil or lipids. Some processes now use hexane, a petroleum product as a solvent to extract the lipids, but that’s expensive. The company’s research, a collaboration with a team at Arizona State, presented its results at the Algae Biomass Summit showing the hexane could be reduced to a third and the time for the process reduced by a third.

The dewatering collaboration with Washington State University on the dewatering of algae uses direct-current and sacrificial metal electrodes in a process called electroflocculation (EF), or electrocoagulation (EC). Those results show that 99.9% of the algae was removed from the samples in about 20 minutes with costs perhaps lower than one penny per gallon. Those are significant cost reductions.

OptiSwitch’s technology is another example of an old, commonly used process researched, developed and uniquely applied to make a completely new and different process application in completely different field.

Now, back to the research ready for market. OptiSwitch has asked Anna Austin at Ethanol Producer Magazine for an article that is quite complete in exploring the corn ethanol design process. It’s a couple of pages long and pretty complete. To cover the highlights:

The early research called for a look at an electroporation effort in Germany trying to increase yields in sugar beets. What the Germans tried to do was use a spark between two electrodes. The effort would work, but self eroded which limited the system life and reliability. From that OptiSwitch applied its experience with the high performance semiconductor solid-state switches reengineering for high voltage and amperages.

OptiSwitch conducted experiments at Southern Illinois University at Edwardsville with evaluations at the National Corn -to-Ethanol Research Center. That collaboration found that a significantly high amount of fermentable sugars were released when measured and compared with control samples.

The high power electroporation process is offering a 3% to more than 5% extra ethanol per unit of corn feedstock.

The company’s team has experience in commercial scaled pulsed electric fields built for food pasteurization that kill bacteria. That know how is also being applied to remove the wayward bacteria that contaminate the corn during fermentation.

The main breakthrough is the current handling abilities. The company’s new switches are said to handle “100,000 amps and volts” (a pre apology to Ms Austin, but that quote needs corrected to make more sense). That power handling capability makes the process viable up to a flow rate of about 25 million gallons of ethanol per year, or four units to pre treat a 100 mmgy plant’s throughput. Occupying a small space, the payback could be about 15 months with installation needing only a few days.

A deal is working for a research unit at full scale installed at a large ethanol producer’s facility, due to go online by the fall of 2009.

Important as this is for ethanol production, the story is interesting in the connections from electroporation in medicine, with defense needs for switches on to applied technology in the current field of corn ethanol production with good prospects for use in cellulosic ethanol and on to algae oil production. Where this technology goes from there is another group of problems yet to be understood or today, even yet to exist.

Comments

8 Comments so far

Breaking cell walls and allowing liquid fats out has been a major headache with algae. This will be a big leap forward if successful.

Yes, and so can nuclear bombs break algae walls. This application is crazy…and then you still need hexane. Another great example of algae hyperbole – though most seem to come from penny stock companies or cash strapped companies desperate for any PR they can get.

Thank you so much for your opinion on Poking Holes in Corn for Ethanol | New Energy and Fuel , I totally agree with you. It is fantastic to see a fresh outlook on this and I look forward to more.

I REALLY liked your post and blog! It took me a minute bit to find your site…but I bookmarked it. Would you mind if I posted a link back to your post?

Great read. Thanks for the info!

Thanks for posting. Good to see that not everyone is using RSS feeds to build their blogs 😉

Hello, this is my first time i visit here. I found so many interesting in your blog especially on how to determine the topic. keep up the good work.

Intriguing post. I have been searching for some good resources for solar panels and discovered your blog. Planning to bookmark this one!