Oct

21

New Numbers Equal A Big Synfuel Breakthrough

October 21, 2008 | 8 Comments

Maria Sudiro and her colleagues at the University of Padova, Department of Chemical Engineering in Italy and Foster Wheeler Italiana Spa, Milan, Italy are reporting that a new process could eliminate key obstacles to expanded use of coal gasification. Today’s processes for converting coal into much-needed liquid fuels are uneconomical again at $70 oil and release too much carbon dioxide, a greenhouse gas, and other air pollutants.

The team’s laboratory simulations and comparisons with conventional coal gasification, their system was 71.1 percent more energy efficient, yielded 39.4 percent more fuel and released 31.9 percent less carbon dioxide.

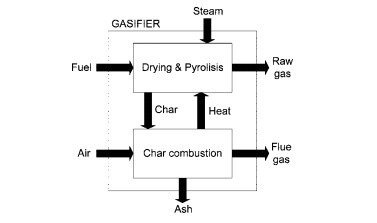

The innovation here is a complex set of testing runs using different process configurations including both power production, by means of an integrated gasification combined cycle (IGCC) plant, and synfuel production, by means of Fischer-Tropsch (FT) synthesis. The basic idea is to thermally couple a gasifier, fed with coal and steam, and a combustor where coal is burnt with air, thus overcoming the need of expensive pure oxygen as a feedstock. As a result, no or little nitrogen is present in the syngas produced by the gasifier. The necessary heat is transferred by using an inert solid as the carrier, which is circulated between the two modules.

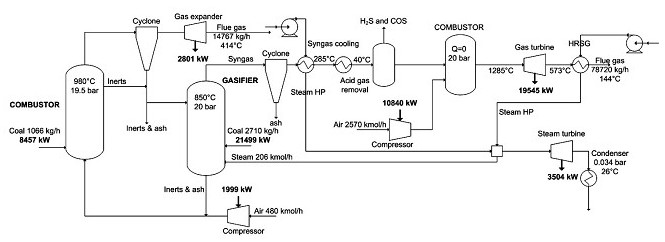

The finalist testing runs is a thermodynamic study of the dual-bed gasification. Then Aspen Plus simulates a dual-bed gasification process, and the efficiency and overall CO2 emissions of the process are calculated and compared with a conventional gasification with oxygen. Eventually, the scheme with the two reactors (gasifier/combustor) is coupled with an IGCC process. This plant configuration simulation is compared with that of a conventional IGCC, where the gasifier is fed by high purity oxygen. With this newly proposed configuration, the global plant efficiency increases by 27.9% and the CO2 emissions decrease by 21.8%, compared to the performances of a conventional IGCC process.

As a second possibility, the same gasifier-combustor configuration is coupled with a coal-to-liquid (CTL) process to convert the syngas into synthetic fuels by a FT reactor. The team showed that, if compared with a conventional CTL plant, the mass yield of liquid synthetic fuel is increased by 39.4%, the CO2 emissions per unit of liquid fuel are decreased by 31.9% and energy efficiency increases by 71.1%.

By every consideration, these are impressive improvements.

Perhaps even more interesting to many is the application of the new principles on biomass fuels. The pdf comments about the FERCO’s SilvaGas process where two reactors are used with sand pumped between them for transferring the heat with reports of high performance results. A commercial scale demonstration plant is running at 200 metric tons per day of capacity.

To convert coal into synthetic fuels, the configuration with two separate reactors (gasifier-combustor) has been coupled with a FT reactor process to convert the syngas into synthetic fuels.

The original goals of avoiding using pure oxygen and reducing the CO2 waste and emission garnered a dramatic improvement in performance. While the paper is based in models, the hardware is running with biomass now making the transition to coal plants a modeling and engineering matter for the vast bulk of the analysis. What is most useful is the news it made, the publication in the American Chemical Society’s peer reviewed Energy and Fuels journal. This is good stuff.

It also illustrates what a determined effort through running many paths from a base to a goal can achieve. When one considers the incredible volumes of coal available to substitute for oil and the pressure to use coal with less CO2 emitted this is an useful enterprise with useful results.

Comments

8 Comments so far

[…] … At low current densities below the 1C-rate, the capacities after the nitridation do not differ much from those for pristine Li 4Ti 5O 12—around 150 mAh g -1. A paper on their work was published online 15 October in the Journal of the American Chemical Society. A number of battery makers … New Numbers Equal A Big Synfuel Breakthrough […]

Today’s processes for converting coal into much-needed liquid fuels are uneconomical again at $70 oil and release too much carbon dioxide, a greenhouse gas, and other air pollutants and new processes could eliminate the key obstacles,this is one of the nice article

It’s really a nice and helpful piece of information. I’m glad that you shared this helpful info with us. Please keep us informed like this. Thanks for sharing.

Hello, this is my first time i visit here. I found so many interesting in your blog especially on how to determine the topic. keep up the good work.

Awesome post. I so good to see someone taking the time to share this information

Good! Thank you! I always wanted to write in my site something like that. Can I take part of your post to my blog?

This post makes a lot of sense !

Great read. Thanks for the info!