Aug

15

The Path to Saving Fuel By Reducing Weight

August 15, 2008 | 5 Comments

It’s weight, then air resistance, and generally overall efficiency in everything else. While oil spirals downward for the next stage in pricing we might be thinking to get lax and relieved, but it won’t last. Months maybe or a year or so and we’ll be spiraling up again.

In the meantime getting set to invest in things that will actually make a significant difference is key. Not just for consumers, but manufacturers too. I’ve saved back a few news bits to lend hope and actually show what manufacturers are getting the idea to offer products with some highly desirable attributes like serious weight reduction.

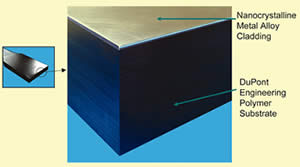

A Canadian firm, Morph Technologies has come up with a process for making assorted vehicle parts out of nano metals with claims the parts are more economical. With new investment from Sustainable Development Technology Canada, Morph is collaborating with auto parts manufacturers hoping to demonstrate two applications if its technology. The technology is called MetaFuse, a nano crystalline metal/polymer hybrid. In lay terms the hybrid is a metal coating over thermoplastic and the nano metal can be used as stock for directly making parts.

The Morph technology as stated by the investor SDTC “Morph Technologies Inc. has developed a nano metal polymer which offers up to 47% weight reduction in engine and drive train vehicle components over equivalent steel parts. The MetaFuse technology combines the cost advantages and formability of plastics with the mechanical properties of metals by marrying high strength nano metal claddings with engineering polymers. This combination allows new designs that reduce the weight of the parts produced, resulting in improved fuel economy and reduced air emissions. The project focuses on different technology applications like: fuel rails (for pressure), valve rockers, transmission spool valves, shift forks (for stiffness and load bearing) or transmission damper skates (for wear).”

Morph is a spin off from another Canadian nano material firm Integran with close ties to the University of Toronto. Dupont Engineering Polymers and Algonquin Automotive have bought in as partners already and Dupont even has an equity stake. Morph is something to watch.

The U.S. Oak Ridge National Laboratory has a new process for making titanium parts that isn’t hot melt so cutting the energy input by perhaps 50%. The product range would drastically increase for titanium with that cost out. Oak Ridge has focused on military use such as doors that protect from those roadside explosions.

The lead researcher at Oak Ridge is Bill Peter who notes that the non-melt approach includes directly making sheets, press and sinter techniques that can shape and produce extrusions. This is a very different set of opportunities for titanium. Peter goes on to say, “This saves a tremendous amount of energy required for processing, greatly reduces the amount of scrap and allows for new alloys and engineered composites.” The introduction of low cost titanium powders plus the new non-melt techniques should bring the famed titanium low weight and extreme strength to more consumer products such as automobiles. The technology is out; Titanium Powders, Ametek and BAE Systems are all in development of technologies to use the powders and non-melt process.

Carbon fiber is a product we’ve heard about for years. Expensive in end products due to the labor involved and the small scale of production it’s been in golf club shafts and other high end or esoteric items. At ten times the strength at one quarter the weight of iron carbon fiber is very attractive. This expense calculation is changing, The Japanese firm Teijin, the world’s second largest producer is up rating production to include a deal with Mitsubishi Chemical for automotive use with expectations of lowering costs and increasing durability.

Then Toray, another Japanese firm, the world’s largest carbon fiber producer announced a deal to develop auto body carbon fiber technology with Honda and Nissan. That might worry other world manufacturers. The plan is to replace enough steel to reduce vehicle weight by 40%. Toray acknowledges that from steel to aluminum the cost factor can be a multiple of 3 to 4 and carbon fiber multiples are from 10 to 100. But steel is getting more expensive and has a limited growth and mines are fully busy now. Carbon fiber has no such limits. With Mitsubishi Chemical involved now, add Mitsubishi Rayon, Toyobo, Seiko, the University of Tokyo and Japan’s Ministry of Economy, Trade and Industry is funding US $18.5 million to start.

Which might be too late, or it was to cover some early costs. Within a few weeks Toray announced with Nissan and “others” that they have developed a technology that speeds up the resin molding process, which makes carbon fiber a mass production item. Toray expects to have the technology commercialized in three years.

Just to cap it all, Toray has announced a new plant, the world’s largest, being built in southwestern Japan will begin production in 2010 at 4,000 tons of annual production, bringing Toray to better than 30,000 tons of total annual production.

It seems the Japanese are intent on improving the personal vehicle’s fuel efficiency by every means possible.

Which makes an American wonder why anyone wastes their time fussing over government mandated fuel mileage. Things are going to get lighter, at least some from Japan, and that’s a good thing.

Comments

5 Comments so far

Whatta nice articles…

Recently most people like to save their fuel in whatever way…

By using hydrogen is one of them…

I just find this blog if u like its articles…

http://hidrogen-fuel.blogspot.com/2008/08/understanding-hydrogen-as-alternative.html

🙂 cool!

found your site on del.icio.us today and really liked it.. i bookmarked it and will be back to check it out some more later

Useful post can i translate into Greek for our sites readers? Thanks

cool content my friend . i will share this to my friend in facebook