Aug

17

A Major Zinc Air Battery Improvement

August 17, 2017 | 5 Comments

University of Sydney researchers have found a solution for one of the biggest stumbling blocks of zinc-air batteries. Zinc-air batteries could overtake conventional lithium-ion batteries as the power source of choice in electronic devices.

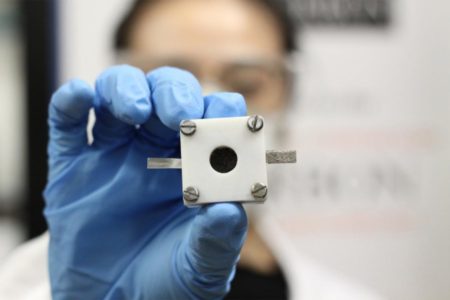

A University of Sydney researcher holds up a rechargeable zinc-air battery. Image Credit: The University of Sydney. Click image for the largest view.

Zinc-air batteries operate with zinc metal and oxygen from the air. Due to the global abundance of zinc metal, these batteries are much cheaper to produce than lithium-ion batteries, and they can also store more energy (theoretically five times more than that of lithium-ion batteries), are much safer and are more environmentally friendly.

Zinc-air batteries are currently used as an energy source in hearing aids, some film cameras and railway signal devices. They are simply disposed of when discharged. Their widespread use has been hindered by the fact that, up until now, recharging them has proved difficult. This is due to the lack of electrocatalysts that successfully reduce and generate oxygen during the discharging and charging of a battery.

According to lead author Professor Yuan Chen, from the University of Sydney’s Faculty of Engineering and Information Technologies, the new method can be used to create bifunctional oxygen electrocatalysts for building rechargeable zinc-air batteries from scratch.

“Up until now, rechargeable zinc-air batteries have been made with expensive precious metal catalysts, such as platinum and iridium oxide. In contrast, our method produces a family of new high-performance and low-cost catalysts,” he said.

These new catalysts are produced through the simultaneous control of the: 1) composition, 2) size and 3) crystallinity of metal oxides of earth-abundant elements such as iron, cobalt and nickel. They can then be applied to build rechargeable zinc-air batteries.

Paper co-author Dr Li Wei, also from the University’s Faculty of Engineering and Information Technologies, said trials of zinc-air batteries developed with the new catalysts had demonstrated excellent rechargeability – including less than a 10 percent battery efficacy drop over 60 discharging/charging cycles of 120 hours.

“We are solving fundamental technological challenges to realize more sustainable metal-air batteries for our society,” Professor Chen added.

Its a bit early to say ‘revolution’, but a cell phone battery with four or five times the capacity of lithium-ion would be welcome, indeed. Assuming the phone manufactures have the sense to make swapping in a new one easy, phone potential would jump up another level.

Comments

5 Comments so far

High-performance and low-cost, which are our common hope!

We trust technology and we trust the wisdom of human, realizing more sustainable metal-air batteries for our society is not dream.

I believe our life will be changed a lot thanks to the development of society. I also believe that the new technology will be the mainstream in the whole society.

Good post! This discovery is good for our environment and sustainable development.

Quite advanced technology! I would like to have a try.