Apr

28

New Battery Tech Recharges Tens of Thousands of Times

April 28, 2016 | Leave a Comment

University of California, Irvine (UCI) researchers have invented a nanowire-based battery material that can be recharged hundreds of thousands of times. Scaled up and marketable the tech would get us closer to a battery that would never require replacement. The breakthrough work could lead to commercial batteries with greatly lengthened lifespans for computers, smartphones, appliances, cars and spacecraft.

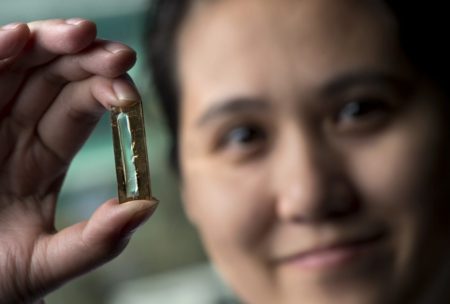

UCI chemist Reginald Penner and doctoral candidate Mya Le Thai (shown) have developed a nanowire-based technology that allows lithium-ion batteries to be recharged hundreds of thousands of times. Image Credit: Steve Zylius at UCI. Click image for the largest view.

The study leader, UCI doctoral candidate Mya Le Thai, cycled the testing electrode up to 200,000 times over three months without detecting any loss of capacity or power and without fracturing any nanowires. The findings have been published in the American Chemical Society’s Energy Letters.

The UCI researchers solved the recharge cycling problem by coating a gold nanowire in a manganese dioxide shell and encasing the assembly in an electrolyte made of a Plexiglas-like gel. The combination is reliable and resistant to failure.

Reginald Penner, chair of UCI’s chemistry department said, “Mya was playing around, and she coated this whole thing with a very thin gel layer and started to cycle it. She discovered that just by using this gel, she could cycle it hundreds of thousands of times without losing any capacity.”

“That was crazy,” he added, “because these things typically die in dramatic fashion after 5,000 or 6,000 or 7,000 cycles at most.”

The researchers think the goo plasticizes the metal oxide in the battery and gives it flexibility, preventing cracking.

“The coated electrode holds its shape much better, making it a more reliable option,” Thai said. “This research proves that a nanowire-based battery electrode can have a long lifetime and that we can make these kinds of batteries a reality.”

Scientists have long sought to use nanowires in batteries. Thousands of times thinner than a human hair, they’re highly conductive and feature a large surface area for the storage and transfer of electrons. However, these filaments are extremely fragile and don’t hold up well to repeated discharging and recharging, or cycling. In a typical lithium-ion battery, they expand and grow brittle, which leads to cracking.

The study was conducted in coordination with the Nanostructures for Electrical Energy Storage Energy Frontier Research Center at the University of Maryland, with funding from the Basic Energy Sciences division of the U.S. Department of Energy.

This is just the kind of thing that is “disruptive” to an existing industry, not that there is any battery tech that isn’t getting disruption right along. But this news is likely to attract the attention of battery researchers worldwide and set off an hunt for better and cheaper versions

Out in the real world a lithium battery is doing pretty well in holding up to buyer expectations at 1-2000 charging cycles. Most electric vehicles are projected in a few years to need a new battery pack. Now suppose that instead of a few years a car needs a new battery pack – the battery pack outlasts several cars.

The economic impact would be enormous. Congratulations to Mya Le Thai, your humble writer’s nomination for the Nobel prize in “serendipity”.