Sep

2

Someday You Might Choose Your Car’s Battery Size

September 2, 2014 | 2 Comments

A study by a team from the Institute of Vehicle Concepts, German Aerospace Center (DLR) on the total cost of ownership (TCO) strongly suggests car manufacturers should develop a modular battery design for plug-in hybrid and extended range electric vehicles (PHEVs and EREVs). That simple change would allow consumers a choice of storage capacity to meet individual customer requirements rather than forcing a “one size fits all” approach.

The study has been published in the journal Energy Policy, where the team makes clear they are not suggesting OEMs offer each customer an individual battery size. The team makes the case by offering as an example, three different battery sizes dedicated to drivers with low, average and high mileage. The study suggests development of a modular design for battery packs could help OEMs to change the size with less effort and few implications on the rest of the vehicle.

The idea is quite similar to the way Tesla Motors markets with its two, that was originally three, battery pack capacity sizes offered in the Model S.

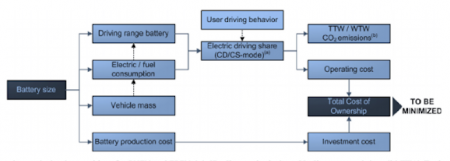

The DLR team analyzed the effect of different driving profiles on the optimal battery setup from a total cost of ownership (TCO) perspective showing that the battery size has a significant effect on the TCO. This does not come as a surprise.

In the study the average German driver who drives 15,000 km/year (9,321 miles), battery capacities of 4 kWh (PHEV) and 6 kWh (EREV) would be cost optimal by 2020. But, the team found the values vary strongly with the driving profile of the user. For example, for an EREV, the optimal size changes to 2 kWh or 13 kWh when respectively, the annual mileage is halved or doubled.

The team recognized optimal battery size is also affected by external factors such as the electricity and fuel prices or battery production costs. The team said, ” . . . the battery is still a very critical component due to the high production cost and heavy weight. Therefore, the right sizing of the battery is the key for electric power trains to meet customer expectations and become cost competitive against conventional technologies.”

The idea isn’t new, and the past work has some major failings in real world application such as not accounting for the heterogeneity across different driver types, not considering that drivers with higher annual mileage typically spend more time on motorways with a higher average velocity than drivers with lower annual mileage with a major effect on energy consumption and the share of electric driving.

The team raises two other points that future buyers will want to have in mind. Previous work hasn’t considered the technical differences between hybrid architectures such as parallel (PHEV) and serial (EREV) configurations. There is always a need for taking into account that batteries are subject to degradation and aging processes which require a substantial over sizing of the initial energy capacity.

The team has taken the fundamentals as they understand them further with a graphic structure of the battery-size optimization problem.

For German market conditions the team considering the battery degradation and secondary effects of additional mass on energy consumption. Their assessment put special focus on the heterogeneity across drivers, by analyzing the impact of different driving profiles on the optimal battery setup from total cost of ownership perspective for the year 2020 in Germany. The most relevant data for this analysis, e.g., energy consumption or battery costs, is based on vehicle simulations and cost models.

They used three representative driving behaviors, based on national data: user A, with 7,500 km (4,660 miles) per year; user B, with the average 7,500 km/year (edit addition: a different driving style); and user C, with 30,000 km (18,641 miles) per year. These a much lower numbers than we experience in North America, but the work makes strong suggestions on which way progress here might go.

Highlight findings are the energy consumption of the PHEV is significantly higher compared to the EREV especially for higher battery sizes. The cost of energy decreased with growing battery size due to the higher share of electric driving. For a given battery size, specific energy costs rise with the mileage of the user.

For PHEV users A, B and C, lowest costs are achieved with battery sizes of 1.5, 3.5 an 5.0 kWh. Then for EREV users A, B and C, lowest costs are achieved with battery sizes of 2.0, 6.0, and 13.0 kWh, respectively, corresponding to 8 km (5 miles), 24 km (15 miles) and 51 km (31.5 miles) of electrical range. Keep in mind that a 13 kWh battery is huge heavy and expensive.

The team also said, which can be a kind of warning, “The results of this paper imply that higher battery capacities would reduce the overall WTW GHG emissions. If the political target is to reduce the GHG emissions even further by encouraging OEMs to design high battery sizes for PHEVs and EREVs, the public authorities may influence the results of TCO by different measure.”

“This can happen in basically two ways: On customer side financial incentives could be provided in the form of a direct purchase bonus or tax benefits which are linked to the battery size of the electric driving range of the new car. Furthermore, policy makers may increase the petrol price by increasing the taxes on it. On OEM side, the legal CO2 regulations could contain norms that reward manufacturers with additional credits depending on the electric driving range of their partial zero emission vehicles (as realized in the ZEV legislation in California). Finally, the electricity to operate plug-in hybrid vehicles in electric mode should be provided from renewable energy sources to reach their full environmental benefit,” they said.

This is the first study of electric vehicle TOC that merits any attention. There is however a huge missing segment, the lighting, and heating and cooling the cabin that needs considered. There are others as well such as ambient temperature effects, hill climbing and more that when added in would immensely impact the results.

For now though, for much of Europe and some segments of the U.S. the market for a computerized sensor to record driving habits is looking like a marketable idea.

Comments

2 Comments so far

“User A” and “User B” in the article are identical.

Sorry, A & B are the noted different driving styles. Thanks for the catch! Edit entered.