Jan

23

Arrival of the Organic Sugar BioBattery

January 23, 2014 | 2 Comments

Y.H. Percival Zhang, an associate professor of biological systems engineering in the College of Agriculture and Life Sciences and the College of Engineering at Virginia Tech said, “Sugar is a perfect energy storage compound in nature. So it’s only logical that we try to harness this natural power in an environmentally friendly way to produce a battery.”

The findings have just been published in the journal Nature Communications.

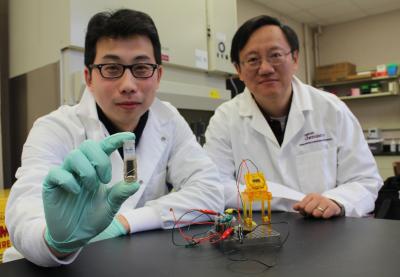

Y.H. Percival Zhang (right), an associate professor of biological systems engineering at Virginia Tech, and Zhiguang Zhu show their new sugar battery. Click image for the largest view. Image Credit: Virginia Tech.

Zhang points out while other sugar batteries have been developed, this one has an energy density an order of magnitude higher than others, allowing it to run longer before needing to be refueled. In as soon as three years, Zhang proposes the new battery could be running some of the cell phones, tablets, video games, and the myriad other electronic gadgets that require power in our energy-hungry world.

“Sugar is a perfect energy storage compound in nature,” Zhang said. “So it’s only logical that we try to harness this natural power in an environmentally friendly way to produce a battery.”

In America alone, billions of toxic batteries are thrown away every year, posing a threat to both the environment and human health, according to the Environmental Protection Agency. Zhang’s development could help keep hundreds of thousands of tons of batteries from ending up in landfills.

This is one of Zhang’s many successes in the last year that utilize a series of enzymes mixed together in combinations not found in nature. He has published articles on creating edible starch from non-food plants and developed a new way to extract hydrogen in an economical and environmentally friendly way that can be used to power vehicles.

In this newest development, Zhang and his colleagues constructed a non-natural synthetic enzymatic pathway that strip all charge potentials from the sugar to generate electricity in an enzymatic fuel cell. Then, low-cost biocatalyst enzymes are used as catalyst instead of costly platinum, which is typically used in conventional batteries.

Like all fuel cells, the sugar battery combines fuel – in this case, maltodextrin, a polysaccharide made from partial hydrolysis of starch – with air to generate electricity and water as the main byproducts.

“We are releasing all electron charges stored in the sugar solution slowly step-by-step by using an enzyme cascade,” Zhang said.

Different from hydrogen fuel cells and direct methanol fuel cells, the sugar as fuel solution is neither explosive nor flammable and has a higher energy storage density. The enzymes and fuels used to build the device are biodegradable.

The battery is also refillable and sugar can be added to it much like filling a printer cartridge with ink.

Now for the impressive details. The team shows that nearly 24 electrons per glucose unit of maltodextrin can be produced through a synthetic catabolic pathway that comprises 13 enzymes in an air-breathing enzymatic fuel cell.

The enzymatic fuel cell is based on non-immobilized enzymes that exhibit a maximum power output of 0.8 mW cm−2 and a maximum current density of 6 mA cm−2, which are far higher than the values for systems based on immobilized enzymes.

The enzymatic fuel cells containing a 15% (wt/v) maltodextrin solution have an energy-storage density of 596 Ah kg−1, which is one order of magnitude higher than that of lithium-ion batteries. Sugar-powered biobatteries could serve as next-generation green power sources, particularly for portable electronics.

The new release leaves virtually all the engineering and usability questions unanswered. It is for now a lab model with prototyping and development to come. Zhang is optimistic and with nearly 600 Ah kg−1 he should be and we are hopeful as well.

Comments

2 Comments so far

Sweet!

I think this is among the most vital information for me.

And i am satisfied reading your article. But want to remark

on some general things, The website style is great, the articles is truly

excellent : D. Good process, cheers