Jun

6

A Graphene Catalyst to Replace Platinum in Fuel Cells

June 6, 2013 | 2 Comments

The team from South Korea, Case Western Reserve University and University of North Texas published their findings yesterday in Nature’s Scientific Reports that is open for readers, saying the new catalyst is a step toward eliminating what the fuel cell industry regards as the largest obstacle to large-scale commercialization of fuel cell technology.

Liming Dai, the Kent Hale Smith Professor of macromolecular science and engineering at Case Western Reserve and one of the report’s authors said, “We made metal-free catalysts using an affordable and scalable process. The catalysts are more stable than platinum catalysts and tolerate carbon monoxide poisoning and methanol crossover.”

In their initial tests a cathode coated with one form of catalyst, graphene nanoparticles edged with iodine, proved more efficient in the oxygen reduction reaction generating 33 percent more current than a commercial cathode coated with platinum can generate.

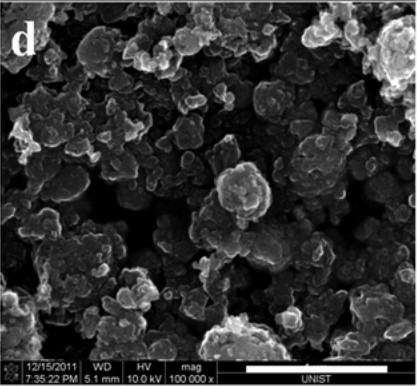

Catalyst of Graphene Doped with Iodine for Fuel Cells. Scale bars are 1 μm. The average grain sizes of finished catalyst are reduced to less than 1 μm. Click image for the largest view. Click the link above to the research paper for more images.

In a test of durability, electrodes coated with the nanoplatelets maintained 85.6 percent to 87.4 percent of their initial current after 10,000 cycles while the platinum electrodes maintained only 62.5 percent.

Like a battery, a fuel cell converts chemical energy into electrical energy. It works by removing an electron from a fuel, usually hydrogen or methanol mixed with water, at the cell’s anode, or positive electrode, creating a current.

Hydrogen ions produced then pass through a membrane to the cathode, or negative electrode. Here, oxygen molecules from the air are split and reduced by the addition of electrons and combined with the hydrogen ions to form water and heat – the only byproducts.

A better, cheaper catalyst than scarce and costly platinum is required if hydrogen fuel cells and direct methanol fuel cells are to become realistic alternatives to fossil fuels, the authors say.

The technology to make alternative catalysts builds on a simple and cheap industrial process several of the researchers developed to make graphene sheets from graphite.

Inside a ball miller, which is a canister filled with steel balls, the researchers broke graphite down into single-layer graphene nanoparticles. While the canister turned, they injected chlorine, bromine or iodine gas to produce different catalysts.

In each case, gas molecules replaced carbon atoms along the zigzag edges of nanoplatelets created by milling. Not only were the edges then favorable to binding with oxygen molecules, but also the bond strength between the two oxygen atoms weakened. The weaker the oxygen bonds became, the more efficiently the oxygen was reduced and converted to water at the cathode.

In testing, a cathode coated with iodine-edged nanoplatelets performed best. The cathode coated with bromine-edged nanoparticles generated 7 percent less current than the commercial cathode coated with platinum, the chlorine-edged nanoplatelets 40 percent less.

Carbon monoxide was added to replicate the poisoning that many scientists blame for the poor performance of platinum at the cathode. The performance of the graphene-based catalysts was unaffected.

When methanol was added to replicate methanol crossover from the anode to cathode in direct methanol fuel cells, the current density of the platinum catalyst dropped sharply. Again, the graphene-based catalysts were unaffected.

A low cost graphene base doped with iodine catalyst with 33 percent more current, electrodes maintaining 85.6 percent to 87.4 percent of their initial current after 10,000 cycles made in an industrial process looks to be a winner.

“This initial research proves such catalysts work better than platinum,” Baek said. “We are working now to optimize the materials.”

There is a long string of alternate catalyst announcements so far. One hopes one breakthrough will finally go to commercial scale and achieve commercial adoption. If a new catalyst would run on methane with the results reported in this post the market would make itself from the efficiency gain alone.

Comments

2 Comments so far

Ha! Very cool, and it looks as if it’s robust. Tantalizing…needs more testing…but tantalizing.

Now we need an efficient system for methane-to-methanol. ARPA-e knows this, funded research for a novel, low-energy system in 2012. How’s it working? Dunno, but lots of groups are looking at this challenge. With very cheap MeOH in hand, transportation fuel looks very different.

what is there in your mind?