Oct

24

A Two Step Pyrolysis For Making Fuels

October 24, 2012 | Leave a Comment

The new gasifier is a second step in a two-stage pyrolysis process.

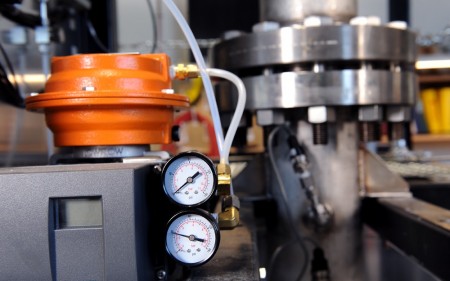

The ISU team starts with a dark gray pipe that’s a few inches across, its wrapped in insulation and fits inside the pressure vessel. It’s the system’s reactor. It’s made of silicon carbide and can operate at temperatures exceeding 1,800 degrees Fahrenheit. The pressure vessel is a 6-inch diameter, stainless steel pipe, which is essential for the system’s operation. It’s a little over three feet long and about a foot across. It can contain pressures up to 700 pounds per square inch.

A finger-sized nozzle mixes bio-oil with oxygen and sprays it into the top of the reactor. The system uses toggle switches, electronics, pipes, a sturdy frame and some very thick bolts to make a bio-oil gasifier. The device allows ISU researchers to combine two thermochemical technologies to produce the next generation of fuels from renewable resources such as corn stalks and wood chips.

To get the bio-oil biomass is fed into a fast pyrolysis unit where it’s quickly heated without oxygen. The end product is a thick, brown oil that can be refined and further processed into fuels. Researchers sometimes describe bio-oil as “densified biomass” that’s much easier to handle and transport than raw biomass.

Then the bio-oil is sprayed into the top of the team’s new gasifier where heat and pressure vaporize it to produce a combination of (mostly) hydrogen and carbon monoxide that’s called synthesis gas.

Synthesis gas can be processed into transportation fuels. It can also be used as boiler fuel to create the steam that turns turbines to produce electricity.

Robert C. Brown, the director of Iowa State’s Bioeconomy Institute, an Anson Marston Distinguished Professor in Engineering and the Gary and Donna Hoover Chair in Mechanical Engineering explains the goal, “We hope to be able to use cellulosic biomass as opposed to using corn grain for the production of fuels. This helps us move toward cellulosic biofuels.”

Brown explains the predicament: researchers have yet to perfect ways to biologically break down plant cellulose to get at the sugars that are converted to fuels. And so the Iowa State researchers are turning to nature’s solution. “Nature uses high temperatures to quickly decompose biomass,” Brown said.

The new bio-oil gasifier has been fully operational since June and has been converting bio-oil made from pine wood into synthesis gas. As the project moves beyond its startup phase, researchers will use bio-oil produced by ISU researchers and fast pyrolysis equipment.

ISUs Kong and Creager with Oil Samples and a Gasifier Core. Click image for the largest view. Image credit: Bob Elbert, ISU.

Looking down the road, Song-Charng Kong, an associate professor of mechanical engineering who’s leading the latter project, will build a computer simulation model of bio-oil gasification. The model will take into account changes in temperature, pressure and biomass. It will allow researchers to understand, predict and ultimately improve the gasification process.

Kong’s computer project will also develop a systems simulation tool that allows researchers to examine the technical, economic and big picture implications of bio-oil gasification. And finally, the project will develop a virtual reality model of a full-size plant that will allow researchers to see, study and improve a plant before construction crews are ever hired.

Kong said, “The physics and chemistry will be behind all these models and images. This is a very new area to study. We can use these models as a tool to understand what will happen as this technology is scaled up.”

The ultimate goal of all the modeling and testing is to develop a new biorenewables landscape for Iowa and the country. The ISU idea calls for biomass to be transported to small, local fast pyrolysis plants that would convert crop biomass into liquid bio-oil. The bio-oil would be easily transported to bigger, regional facilities where it could be gasified and processed into transportation and boiler fuels.

For now Creager is at the high bay facility on the north side of Iowa State’s Biorenewables Research Laboratory putting the bio-oil gasifier back together after completing some gasification trials. The plan is to run the gasifier at higher pressures later, which is required for efficient fuel synthesis.

Once the machine is fully tested and operating at full speed, Creager said it could continuously gasify nearly 4.5 pounds of bio-oil an hour, enough to help researchers understand how the technology could one day contribute to an advanced bio-economy.

Pyrolysis is a fine way to process biomass. Its still capital intensive, needs a lot of energy and some expertise to build and operate. But it’s the technology that works with some useful byproducts as well. The ISU team may well make the bio-oil a better value and the processing picture might make the biomass to fuel picture more practical. The questions may not hinge on the technology but the economics.

For that only more research, experimentation and trials at scale will tell the winner.