Jun

21

The Incredible Shrinking LED

June 21, 2011 | 1 Comment

Many expect that LED technology is the electric light source for the future. It would be a very good bet. LEDs offer very low power consumption and long life. The current downside is the initial investment and the replacement cost projection. The economics work, but it takes years.

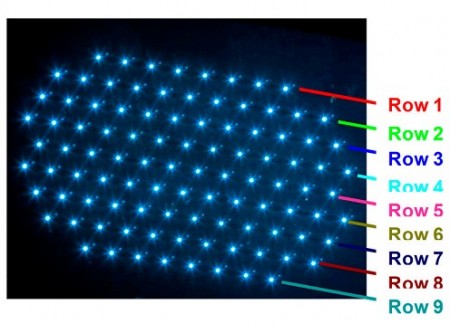

University of Miami professor at the College of Engineering, Jizhou Song, has helped design a LED lamp that uses an array of LEDs one hundred times smaller than today’s conventional LEDs. Some clever build research is paying off with a lab sample with 100 LEDs on a chip.

100 LEDs on a Chip. Research on LED building at the University of Miami. Click image for the largest view.

The new device has design flexibility, maintains lower temperature and has an increased life span over existing LEDs. The findings have been published online by the Proceedings of the National Academy of Science. These may be small, but its no small progress step.

The point of the effort at Miami was focused on improving certain features of LED lights, like size, flexibility and temperature. Song’s role in the project was to analyze the thermal management and establish an analytical model that reduces the temperature of the device.

Song explains his model saying, “The new model uses a silicon substrate, novel etching strategies, a unique layout and innovative thermal management method. The combination of these manufacturing techniques allows the new design to be much smaller and keep lower temperatures than current LEDs using the same electrical power.”

Not satisfied with that the multi university team would also like to make the device stretchable, so that it can be used on any surface, such as deformable display monitors and biomedical devices that adapt to the curvilinear surfaces of the human body.

The paper at the National Academy has a pretty complete review of the build of the new LED design. One can even get a good grasp of the technology from the supporting information. The pleasant surprise is the tiny LEDs when laid out carefully on the chip can be cooled without an airflow or other cooling apparatus. The design simply uses direct thermal transport through the thin-film metallization used for the electrical interconnect. That allows for providing an enhanced and scalable means to integrate the devices into modules for white light generation.

Miami’s press release results introduces an impressive team including John Rogers, the Lee J. Flory Founder Chair in Engineering and professor of Materials Science and Engineering at the University of Illinois at Urbana-Champaign, senior authors include Ralph Nuzzo, G. L. Clark professor of Chemistry at University of Illinois at Urbana-Champaign, and Yonggang Huang, Joseph Cummings professor of Civil and Environmental Engineering and Mechanical Engineering at Northwestern University.

The study paper title “Unusual Strategies for Using Indium Gallium Nitride Grown on Silicon (111) for Solid-State Lighting” could also be “Thoughtful engineering expertise creates a high potential LED design.”

If these fellows can build an LED that could be stretched over a hemisphere at good cost savings the commercial scale will come.

There will be lots of industry engineers checking the study paper very carefully. Its very good work and makes one wonder what more can come from the strategy.

Comments

1 Comment so far

Very nice article.