May

20

GreenCarCongress leads the news about Japan’s Kobe University researchers developing a yeast species capable of directly fermenting ethanol from cellulosic materials. Just how the folks at GreenCarCongress manages that without a press release coming out is a mystery and it also leaves us at some mercy for the writer, Mr. Mike Millikin’s own interpretation. Mr. Millikin is top flight, but lets have another look.

The abstract of the team’s paper explains, “In this study, using our previously developed method to optimize cellulase-expression levels in yeast, we constructed a diploid Saccharomyces cerevisiae (yeast) strain optimized for expression of cellulolytic enzymes, and attempted to improve the cellulose-degradation activity and enable direct ethanol production from rice straw, one of the most abundant sources of lignocellulosic biomass.”

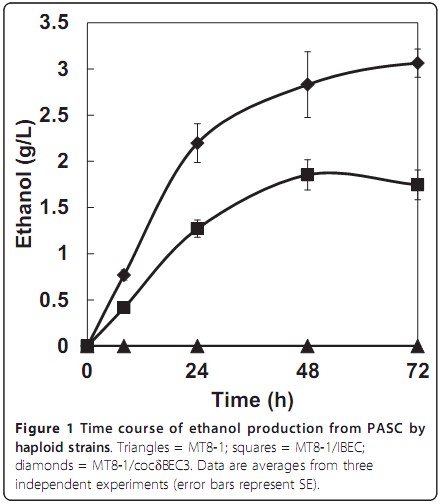

The results? “ . . . displayed approximately six-fold higher phosphoric acid swollen cellulose (PASC) degradation activity . . . When used to ferment PASC, the diploid strain produced 7.6 g/l ethanol in 72 hours, with an ethanol yield that achieved 75% of the theoretical value, and also produced 7.5 g/l ethanol from pretreated rice straw in 72 hours.” Now that 75% recovery of the available theoretical value is quite impressive

New Yeasts Time to Process Cellulose Results Graph. Click image for the largest view. Image Credit: BioMed Central Ltd.

The meat of the conclusion is not so much pointed as getting to the front of the research field. The team says politely, “We have developed diploid yeast strain optimized for expression of cellulolytic enzymes, which is capable of directly fermenting from cellulosic materials.”

And it’s a one-vat treatment, too. As the study conclusion notes, “ . . . it is to our knowledge, the first report of ethanol production from agricultural waste biomass using cellulolytic enzyme expressing yeast without the addition of exogenous enzymes.” In other words there isn’t s powerful chemical or enzyme pretreatment step involved. That simplifies things in a big way and cuts down on the costs to build processing facilities.

The key on this is the genetic modification of the yeast. The Kobe team has introduced not less than three new genes in multiple points along the DNA. What is revealed in the ‘Discussion’ section of the paper is the team isn’t proposing there is certainty as to which gene insertion actually made the yeast so productive. This points up two things. The first is they have a job to do to figure out which placement pays off now and secondly, there is good reason to believe there is room for optimization.

This points up the realization that the Kobe team has a very interesting method to optimize cellulase-expression levels in yeast. The method also works very well at least this once and indicates there is potential for application in other forms.

The team’s paper, Direct Ethanol Production from Cellulosic Materials Using a Diploid Strain of Saccharomyces Cerevisiae with Optimized Cellulase Expression, is published in the journal Biotechnology for Biofuels and is a free pfd download. The technical discussion of the optimization method is absent, as one would expect some intellectual property activity to be underway.

What we do know is the team used a genetic manipulation method that is easy to explain. Two yeast strains were built and mated to make a diploid strain, a descendant with a mix of the DNA from the parents. After going through an undisclosed number of strains the team got its success.

It’s still not a cheap process. Rice straw and other cellulosic materials are still going to need treated to get them in digestible form. For rice straw the simple explanation is clean it twice with hot water, dry it, and grind it very fine. This isn’t going to be as easy as using grains that come nearly ready for processing nor as inexpensive, but biomass should be less costly to acquire.

While this all looks really good the team points out that they have equaled results from materials using to the phosphoric acid swollen cellulose, or PASC. That leaves out the suspected highly crystalline regions of cellulose in the rice straw. Then there is the matter of the hemicelluloses and a lignin matrix surrounding cellulose in the biomass structure. These can be removed or may be addressed with enzymes.

While this post is meant to simplify a complex problem, and the Kobe team has made headway, there is still a way to go. Pulling out 75% is great, but leaving 25% behind and the hemicellulose and lignin is going to leave quite a pile of refuse.

Yet the refuse is going to have value for something. It may be worth more than wood refuse or be a source for other ideas non-fuel in nature. It might be best if the team charges on and makes a refuse pile for examination. Like the algae industry is learning, there might be another path to profit.

It’s great to get to see a full paper without paying an exorbitant sum. The team also has written in a way that many people can understand. It’s not only fine research, it’s research presented quite well, too.

Comments

5 Comments so far

Another step closer to the day farmers will have a silo digesting corn stalks into fuel for the farm. That would isolate farmers from continued economics shocks from the price of oil and would be a major strategic win for American food growers.

I think a enjoyed a period of time to see you here, can also still active. Glad to see you all the recent buzz. .

Musson

Yes, its very interesting indeed!

Have a look also at the article in Science Daily about direct conversion of cellulose to isobutanol, March 7, 2001.

http://www.sciencedaily.com /releases/2011/03/110307124917.htm

ベジライフ酵素液

ダイエット口コミで大人気のベジライフ酵素液の口コミ評判を集めました

Dear ベジライフ酵素液口コミ

Thanks for your ontribution.