May

27

Major Geothermal Drilling Progress

May 27, 2010 | 2 Comments

Potter Drilling’s new technology differs from current air-based techniques because they use hot fluid rather than air to spall the rock. Because spallation occurs in a water-filled borehole, Potter Drilling’s technology can be used to drill to depths required for engineered geothermal system (EGS) plants 12,000 to 30,000 feet. 30K feet is major in that much more heat is available and much more territory becomes viable as a heat source.

The process starts by applying a high-intensity fluid stream to a rock surface to expand the crystalline grains within the rock. When the grains expand, micro-fractures occur in the rock and small particles called spalls are ejected. The process is accelerated by several factors including inherent stress in the rock formation.

Potter Drilling is building on developments of spallation drilling technology. Air spallation drilling was used commercially from 1947 through 1961 for ore mining and was adapted to geothermal drilling by the U.S. Department of Energy in the 1970s. Air spallation demonstrated impressive drilling performance, producing 8in to 12in boreholes to depths of 1,100 feet at rates faster than 50 ft/hr through solid granite.

The engineers at Potter Drilling have developed a spallation-based technology that drills and removes rock without making contact with it – an approach to hard rock drilling they’re claiming has significant cost savings and performance advantages over conventional drilling technology. That seems reasonable, without mechanical contact between equipment and the rock the grinding effect is skipped. One can get an idea of the effect by hammering at granite with a rock hammer and checking one’s progress.

The oil and gas industry’s currently used drilling technology has been optimized over the past century for soft sedimentary rocks where petroleum deposits are found. Sandstone, shales and other sedimentary rocks are much easier to grind apart and the technology works well for extracting fossil fuels, but it’s not well suited for the crystalline hard-rock environment.

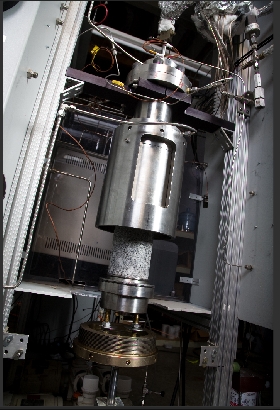

Potter Drilling has tested two different laboratory prototype drills proving that the hydrothermal spallation can be effective in a wide range of rock types from the surface to deep borehole conditions. The demonstrated penetration rates approach 30 ft/hr – five to 10 times higher than is achievable using conventional rotary contact bit technology common in the soft rock drilling field.

Potter Drilling is now proposing to construct a complete prototype drilling system and to conduct field trials to determine the technology’s real-world performance.

Potter Drilling is dedicated to reducing geothermal well costs, making widespread use of engineered geothermal systems an affordable alternative to other power sources. Drilling can represent more than 50% of the total cost of well development, so reducing drilling costs will significantly improved the economics of EGS-development.

The cost breakout for geothermal drilling are listed as rock penetration at 30 to 40%, pulling and reinserting the string of drill pipe at 10 to15%, the bore casing and cementing the casing 33 to 38%, planning running 3 to 8% and trouble allowance 8 to 10%. Potter Drilling’s technology has the potential to reduce the cost of completed EGS wells by 30% to 60% through faster rates of penetration, less tripping time, and dramatically reduced wear, resulting in more linear cost increases with depth. The goal is to move the cost curve for drilling hard-rock wells from exponential cost increases with depth to linear cost increases with depth – dramatically lowering the cost for developing EGS systems.

It seems that the “bit” is really a reaction chamber where unnamed chemical reactants heat the water to 800º C. The water is forced through a nozzle introducing stress to the rock where expansion differences fracture out spalls. The water then carries the spalls out of the well bore.

Potter Drilling isn’t your typical venture capital funded idea. Bob Potter is 88. The bait of geothermal is very tasty, the 2006 MIT study suggested that geothermal could provide 2,500 times the energy now used in the U.S.

The obvious issues are getting the energy down the hole to heat the water, and keep the heating chamber and nozzle from melting or wearing away as 800º C is awfully hot. The challenges are significant, but the payoff would be huge.

Jared Potter, Bob’s son who Bob recruited to run Potter Drilling says, “We think we can cut the cost by 50 percent.” Maybe so, maybe better as the full range of those drilling costs are addressed.

The technology should be in the field in 2010 for prototype trials. As a new, complex and untried device if it works at all outside of the lab – will be significant.

Hydrothermal spallation was invented and patented by co-founder Bob Potter and Jefferson Tester of MIT. The patent is owned by MIT and licensed exclusively to Potter Drilling. Rig guys, you might want to follow Potter’s progress.

Comments

2 Comments so far

All week I have been reading about drilling tech, for my money the white granite pictures show some of the potential and at 30k feet things get very interesting.

Keep posting stuff like this i really like it