Feb

4

A Totally New Way to Build a Hybrid Drive

February 4, 2009 | Leave a Comment

Lino Guzzella, Professor of Thermotronics at the ETH Zurich Machinery Laboratory of Zurich Switzerland (Swiss Federal Institute of Technology) doesn’t think the electric hybrid is the only solution. Guzzella explains, “The apple must be ripe but still hang just low enough to stay within reach.” The idea is a pneumatic hybrid drive.

The new hybrid engine has a compressed air tank connected to the engine instead of a generation set and a battery unit. As needed, such as starting from stopped or at a gear change, compressed air flows into the engine through an electronically controlled valve. Plus, if fuel is also injected, the engine responds quickly with more power from the saved enthalpy. The approach is simpler than an electric hybrid but remains affordable even for people with less purchasing power.

The ingenuity answers several problems that parallel electric hybrids (the Toyota Prius type) bring to the engineering problem. It is expensive to engineer and capitalize the manufacturing facility. Batteries are needed and remain an expensive storage solution, plus dramatically add weight. Controlling both an internal combustion and electric power inputs for good drivability is a complicated computing and electrical switching and metering issue to match and assist while interfacing with mechanical drive.

Even in a series hybrid (The Chevy Volt) where the mechanical connection is just the connection to the generator the battery weight issue and the expense issues remain.

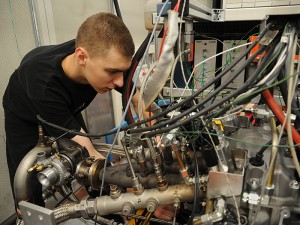

The Guzzella design using compressed air allows the engine constructors to achieve extreme downsizing. Conventional car engines can have peak powers of 150 hp or more, but usually need no more than say 30 hp for everyday driving. Downsizing the research engine halves the number of cylinders from four to two. This also halves frictional losses and increases the engine’s average efficiency. To keep the desired maximum power and thus satisfy the consumer’s drivability demands, the engine is highly supercharged by a turbocharger – which exploits the exhaust gas enthalpy as an energy source, and which boosts the power output to the desired level.

The initial reported test stand results show that Guzzella and his group are on the right track. They were able to increase the engine’s average efficiency in the European Test Cycle from 18 to 24 percent. That works out to a fuel saving of one third. Energy savings of up to 50 percent are achievable in purely urban traffic, because the engine can pump air into the compressed air tank during braking, thus recovering the kinetic energy from the moving mass.

The fuel saving achieved by the pneumatic hybrid is not as large as that of an electric hybrid, it still comes in at 80% of the parallel hybrid layout. The price-performance ratio is distinctly better. So good, in fact, that Guzzella can imagine the pneumatic hybrid also being affordable for use in underdeveloped countries. In the Swiss mind of costs, Guzzella estimates the additional costs compared to a conventional gasoline engine to be approximately 20 percent. On the other hand, the additional costs for an electric hybrid are calculated to be at least 200 percent.

These are difficult numbers to qualify or quantify. Yet the reasoning behind a optimized engine efficiently running at 30 hp with a power reserve 5 times higher with ready to access compressed air at pressures high enough to equal engine compression around 150 psi or more is very attractive. The adding of fuel to the compressed air in accurate amounts would likely offer sparkling performance.

The new engine concept has aroused the interest of several major motor companies and automotive suppliers, who have obtained information at Zurich. Some of the ideas of the new concept have already been patented. Guzzella says he is convinced that he will find people interested in adopting this system, since no other technology is on the horizon that can replace the internal combustion engine.

You have to admit, this is an ingenious idea. Hybrids in both series and parallel forms have steep engineering, manufacturing and sales issues to overcome. Using compressed air offers very simple, low cost and common manufacturing techniques to get to better efficiency.

Just how the variances between a cylinder charge with ambient fueled air, turbocharged fueled air, compressed air and compressed fueled air with their various temperatures and densities is handled promises to be very interesting.

The technical paper is due to appear in the Soc. of Automotive Engineers, April 2009. It is no surprise that the details have gotten out so early. I’m looking forward to this.