Mar

28

Another Way to Bio Gasoline

March 28, 2008 | 1 Comment

Wednesday Royal Dutch Shell and Virent Energy Systems of Madison Wisconsin announced their collaboration to develop biogasoline. The deal is using the existing research and development work of Virent in catalysts that convert plant sugars into hydrogen and fuel gas, a combination of hydrogen, methane, propane and CO2. The research so far has been quite successful in bringing hydrogen off the sugar stock good enough to power a fuel cell with leftover fuel gas that can be used in other ways.

The collaboration seeks to use the research to go further on to a commercial synthetic gasoline. The partners believe it is worthwhile to use the catalyst path to convert plant sugars into hydrocarbon molecules like those produced at a petroleum refinery. Historically man has relied on yeasts to ferment to the alcohol hydrocarbon family, but Shell and Virent realize that going on to the higher energy densities of gasoline, diesel, and jet fuel offer both reduced costs at the consumer level for the investment in equipment and the producer’s storage and transport expenses to make products available.

The press release from the Shell site offers that the feedstocks would be from a broad base of possible non-food sources listing things like corn stover, switchgrass and straw as well as the corn kernels, wheat grains or sugarcane. How accurate that statement is will take time to determine, as the process that can be reviewed outside of the private proprietary details starts with plant sugars and leads to the hydrogen fuel gas products. The enzymes for corn and wheat to push the starch up to sugar are available, but corn stover, straws, and switchgrass are still in the nebulous stage of being cellulosic, not sugar compounds, for now.

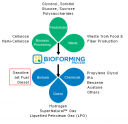

With a year behind the partners already working together the news must have some viability. Shell or Virent, or as partners, have trademarked “BioForming” technology and state that the technology has advanced quickly and exceeded their milestones for yield, product composition and cost. The future effort will focus on improving the technology and scale up for large volume commercial production.

Not to stop there, Shell’s Executive Vice President Future Fuels and CO2 said in part “. . . new fuels on the horizon such as Virent’s, with characteristics similar or even superior to gasoline and diesel are very exciting.” Ah, an understatement, I think. Dr. Randy Cortright, Executive Vice President, Virent’s chief technology officer and co-founder said, “Virent has proven that sugars can be converted into the same hydrocarbon mixtures of today’s gasoline blends. Our products match petroleum gasoline in functionality and performance. Virent’s unique catalytic process uses a variety of biomass-derived feedstocks to generate biogasoline at competitive costs. Our results to date fully justify accelerating commercialization of this technology.”

But the cellulose to sugar matter isn’t resolved. Having another process from plant sugars on to full dose, energy dense, don’t have to replace/modify a billion engines worldwide is great. That cellulose thing that bedevils the ethanol folks is bedeviling here, too? Well, I have calls and emails off to find out.

Virent is the exclusive licensee of the aqueous phase reforming (APR) process – developed by Dr. Cortright and Dr. Jim Dumesic while at the University of Wisconsin, Madison, that converts biomass sugars into carbon neutral fuels or the hydrogen fuel gas path. APR is low cost in that the operating temperatures are in the 180 to 260 degree Centigrade range. The process is thought to be highly efficient in the use of the catalysts. Comparatively low operating pressures are involved. The process operates below the pyrolysis threshold, minimizing decomposition reactions. The feedstock choices come from a wide range of biomass as well as waste products such as glycerin that is building up as it’s removed from biodiesel fuel.

Virent calculates that the BTUs from a crop such as corn could be multiplied out more than 2.4 times from current BTU yield. The APR process itself is adjustable offering a broad range of products from hydrogen on to light liquid petroleum gas such as propane and still on to middle distillates such as diesel and jet fuel.

Is it all real? Very, very likely, as the effort by Shell to publicize and offer as much non-proprietary information as they can in such short order. Moreover, oil companies like Shell have state of the art know how and experience in catalytic reforming and some might have made its way to Virent.

This announcement offers another path from plant sugars, a biological formed source, for using this new chemical process to yield ready to use fuels. While we looked at these other processes here, another that offers lower costs would be welcome. Its also worth noting that the chemical bioconversion using pyrolysis taking biomass to a form of crude oil would bypass the sugar step while still requiring a refining process. The ways from biomass to fuel are getting numerous and soon we’ll be able to assess what paths will cost what investment and be how efficient on a fuel unit per land area unit.

One question is likely to be popular soon. The APR process may quickly displace the ethanol from the corn process as the plants already have facilities that prepare the corn to sugar and have the facilities to use the leftover protein and fiber. Should the APR process be economically adaptable, adoption could be very quick canceling a large share of the ethanol processes fossil fuel use in the distilling segment of production and providing a much easier to transport and use product that has a much higher energy density. Moreover, the APR process may well use the glycerin in the corn oil from the remaining distillers grain yielding even higher value.

This might be a turning point for biomass to fuel. On the other hand that cellulose to sugar issue is still out there. But it looks like each passing day brings technology closer to an economy based more and more on a recycled carbon fuel world, leaving fossil petroleum for the generations to come.

Comments

1 Comment so far

[…] Another Way to Bio Gasoline […]